Board position detection method and device

A detection method and board card technology, which are applied in measurement devices, optical devices, image enhancement, etc., can solve the problems of high complexity and high cost of board position system, and achieve the effect of reducing cost and precise positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

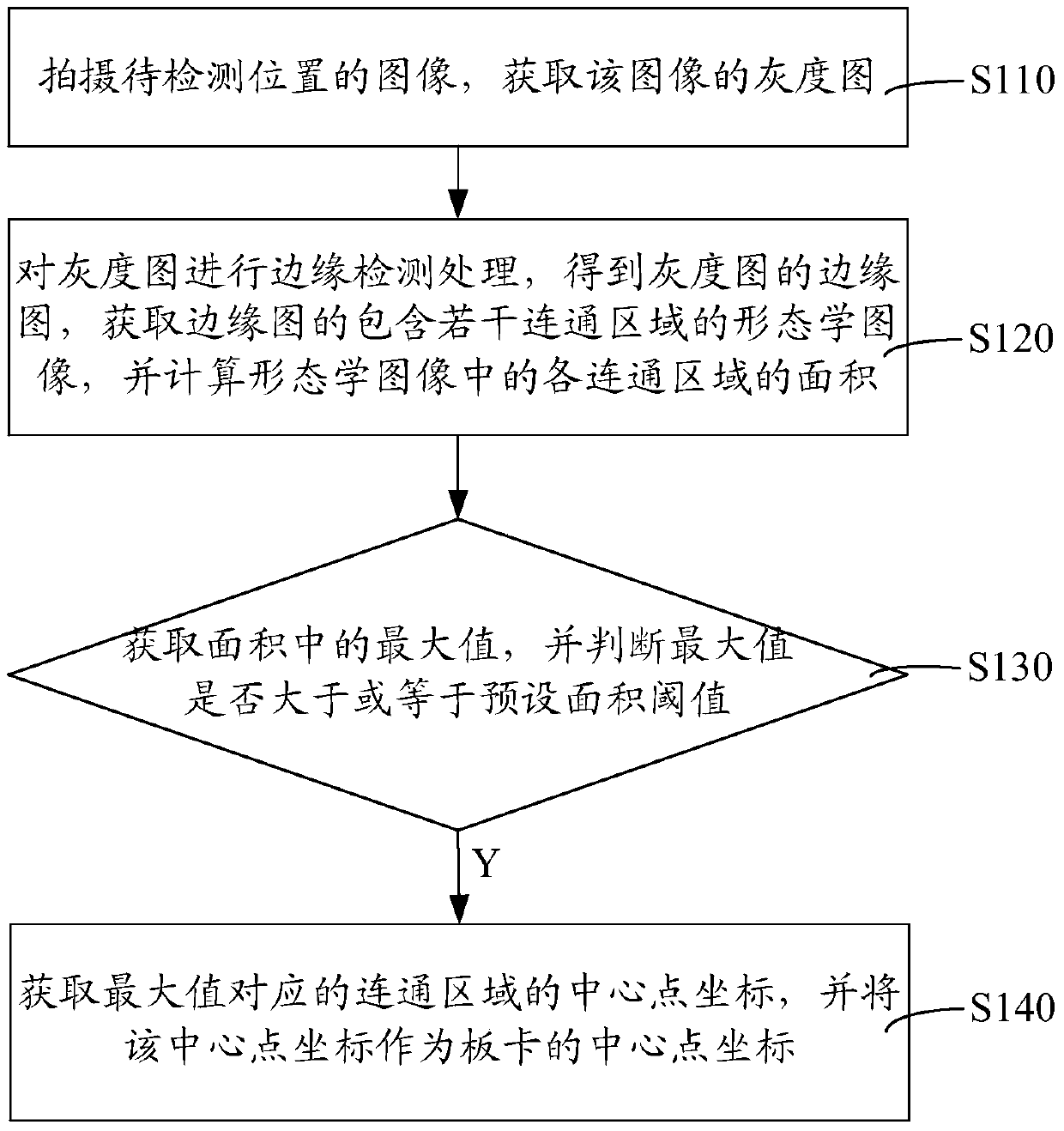

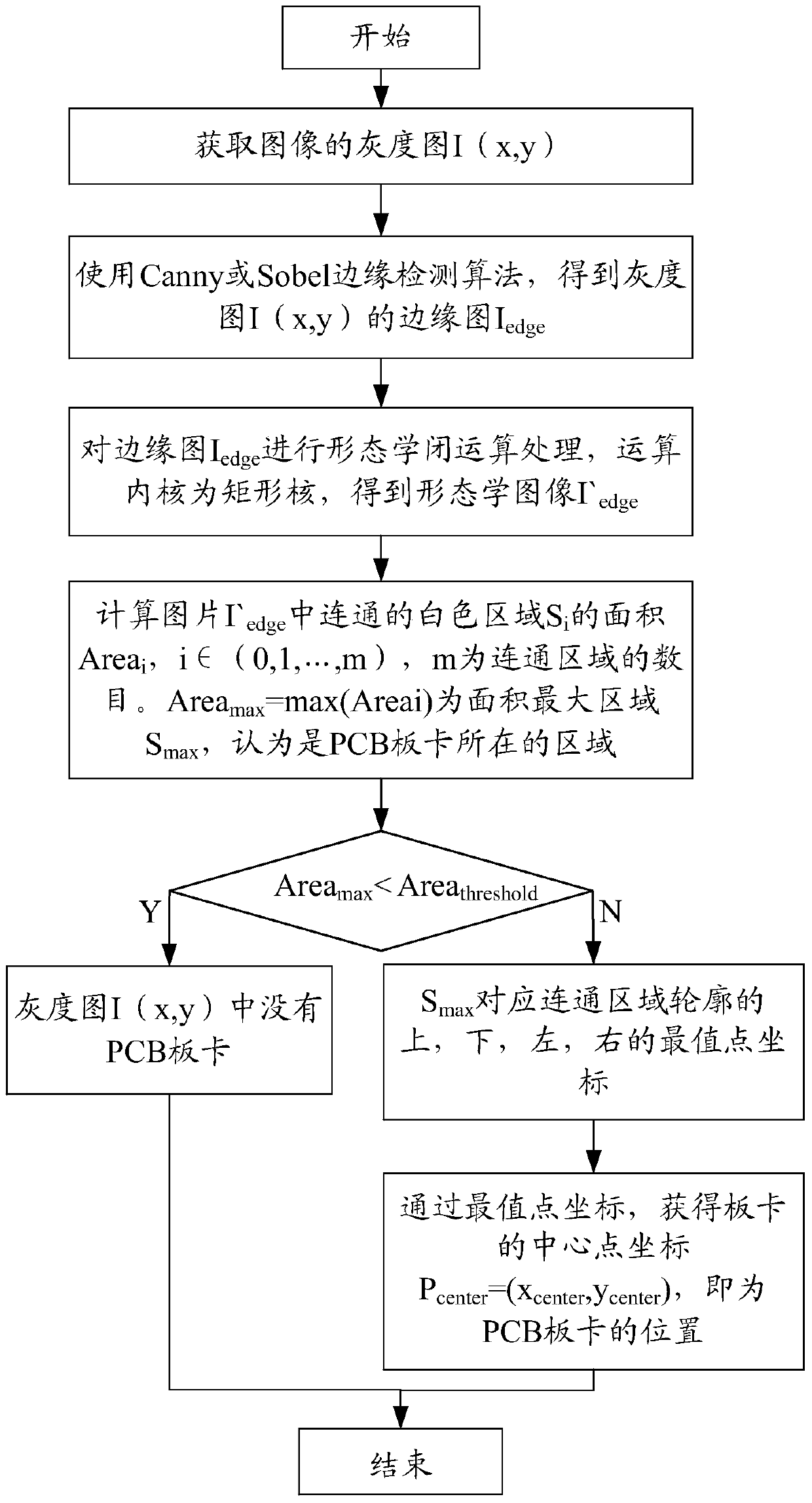

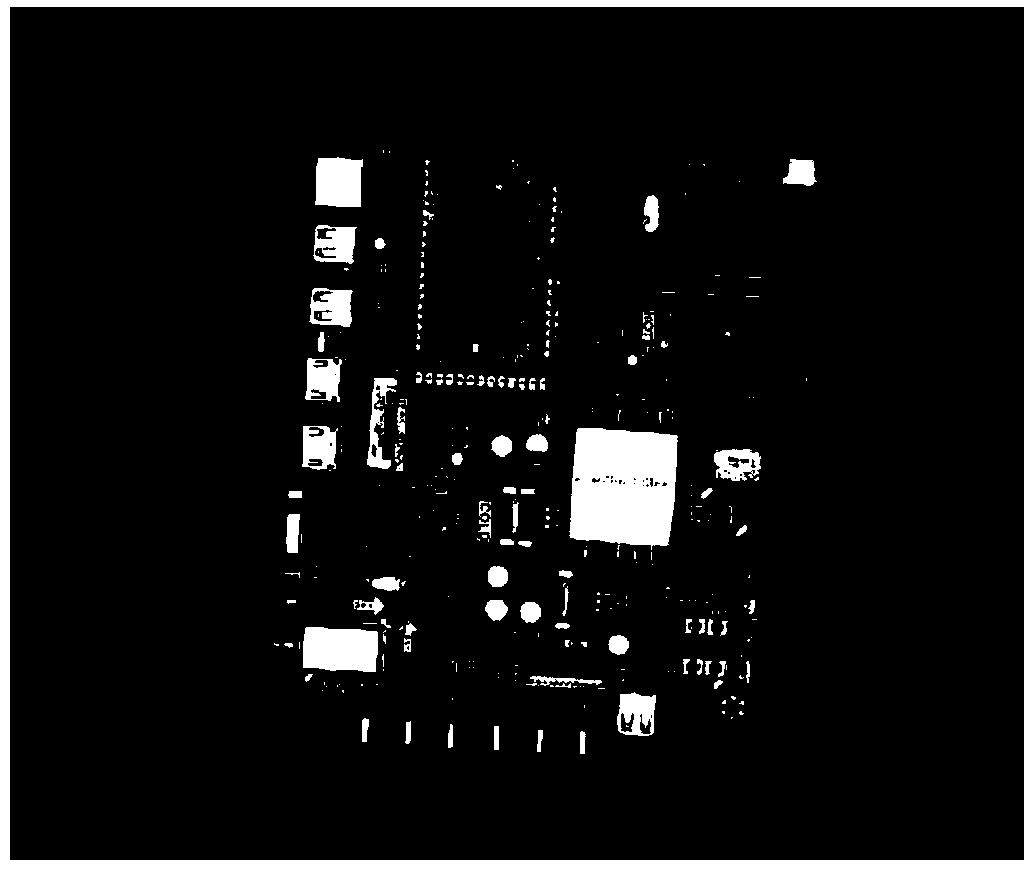

Method used

Image

Examples

Embodiment 1

[0075] Aiming at the technical problem of judging the position of the board by the AOI system, the present invention also provides a device for detecting the position of the board; Image 6 It is a structural schematic diagram of Embodiment 1 of the board position detection device of the present invention, as Image 6 Shown: The board position detection device includes:

[0076] The image acquisition module 610 is used to take an image of the position to be detected, and obtain a grayscale image of the image; in a specific embodiment, obtain the grayscale image of the image captured by the AOI system assembly line camera;

[0077]The image processing module 620 is used to perform edge detection processing on the grayscale image to obtain an edge image of the grayscale image; and obtain a morphological image of the edge image that includes several connected regions; and calculate the area of each connected region in the morphological image ; In a specific embodiment, promptl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com