A cryostat for superconducting cables

A cryostat and superconducting cable technology, applied in superconducting devices, usage of superconducting elements, superconducting/high-conducting conductors, etc., can solve problems such as high cost of use, lack of flow meters, and fast consumption of liquid helium , to achieve the effects of low production and use costs, real-time monitoring of calorific value, and meeting low temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

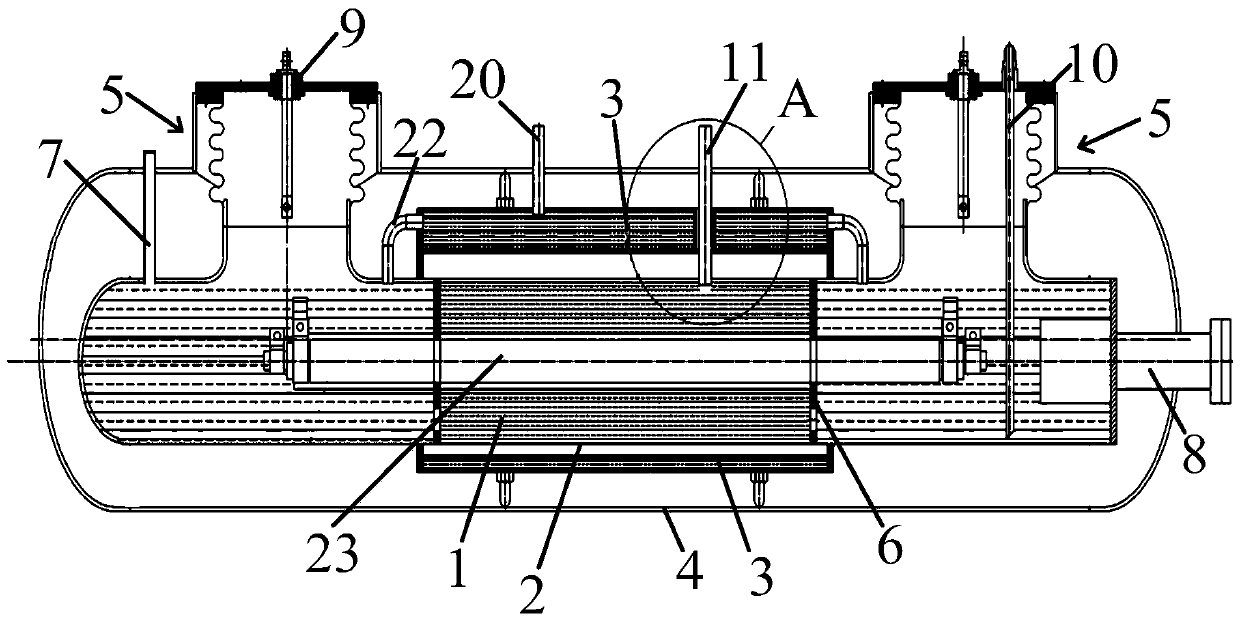

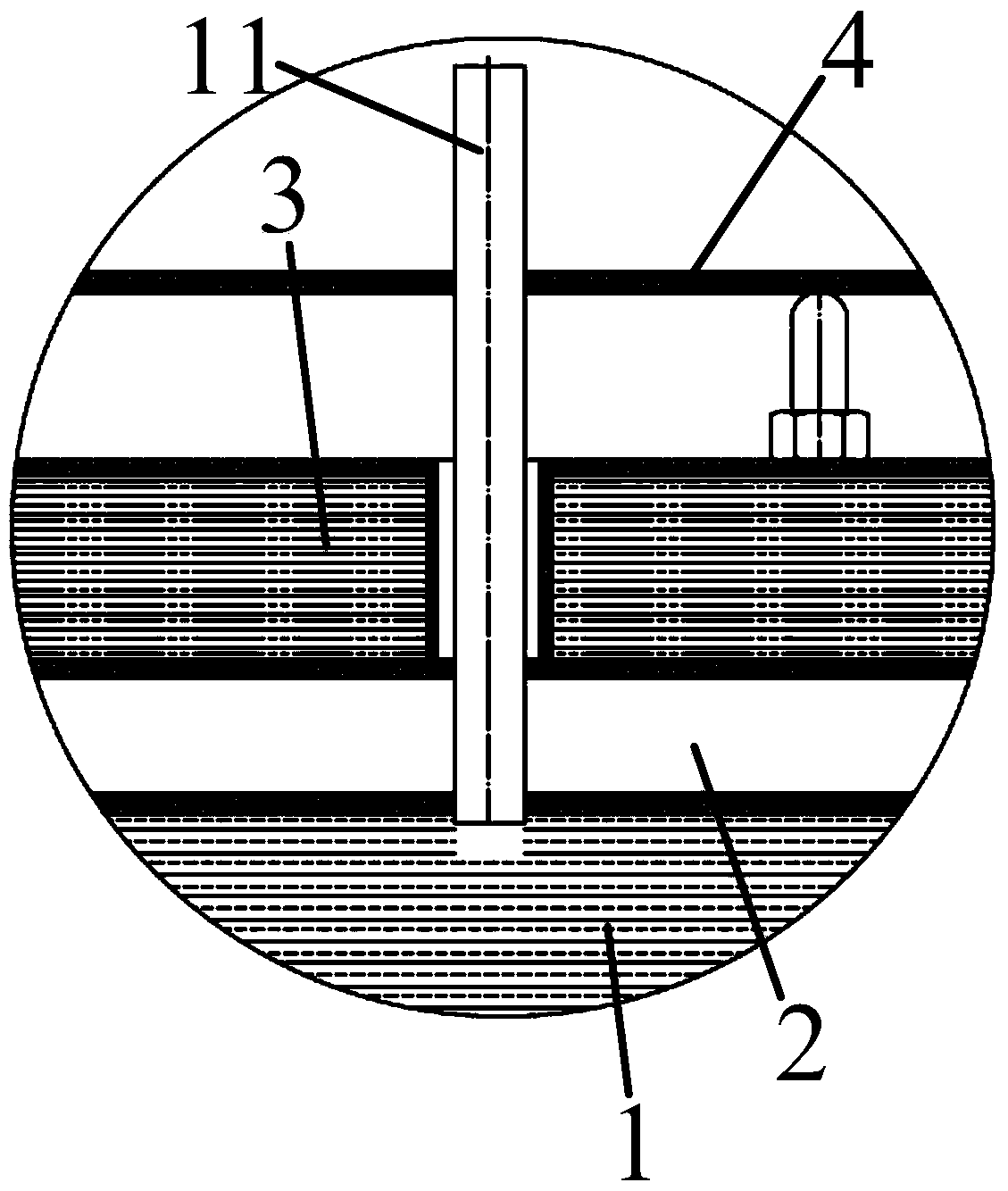

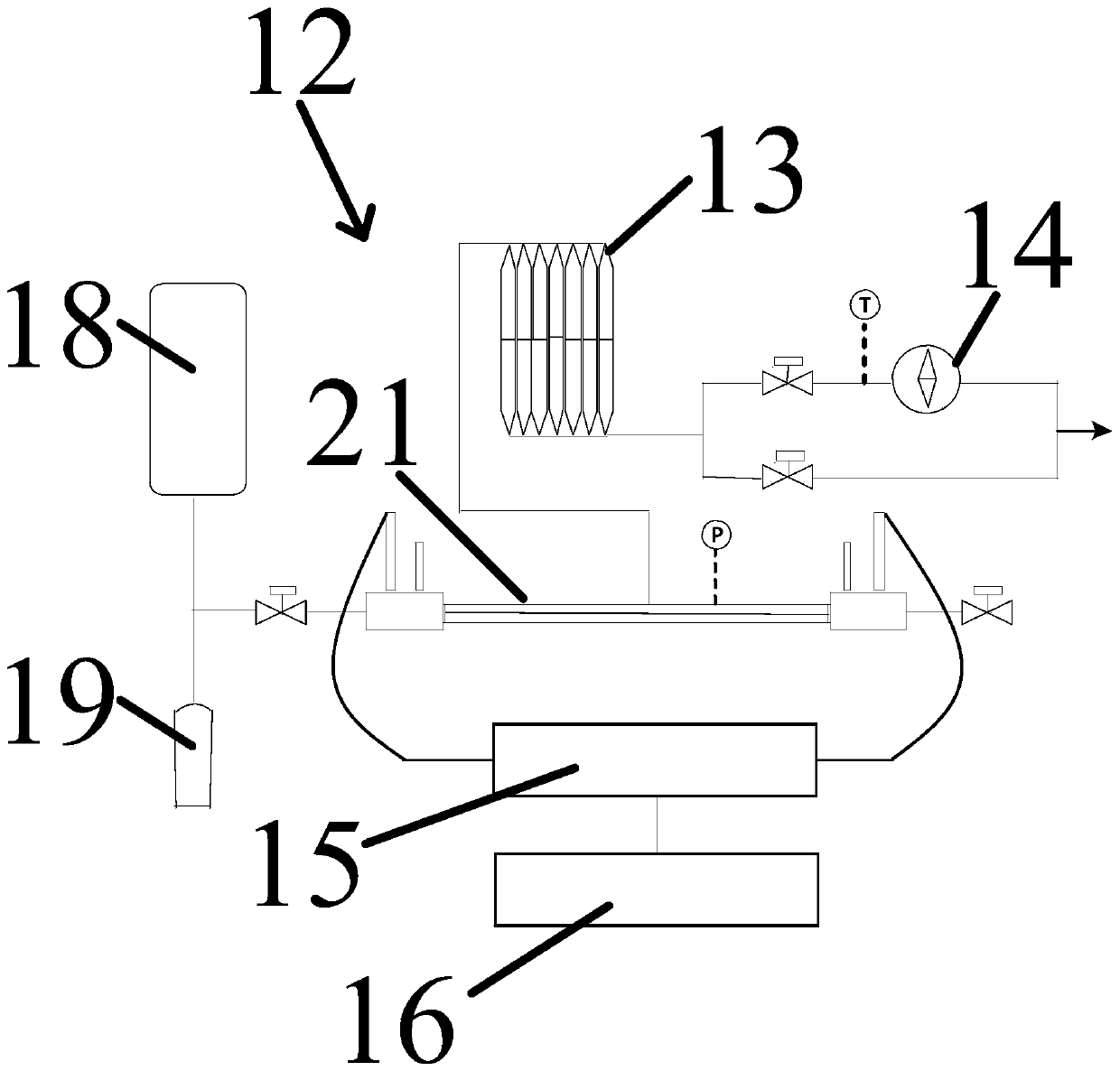

[0030] Such as figure 1 As shown, a cryostat for a superconducting cable, the superconducting cable 23 includes a cable skeleton located at the axis of the cable and a superconducting tape, an insulating tape, and a low-temperature holding inner of the cable skeleton arranged outward in sequence. tube, insulating layer and outer sheath; the cryostat includes a cooling jacket 1, a vacuum jacket 2, a liquid nitrogen cooling Screen casing 3 and shell 4,

[0031] Both ends of the cooling jacket 1 connected to the calorific value measuring device 12 are respectively connected to a liquid nitrogen cold shield 5 containing liquid nitrogen.

[0032] The liquid nitrogen cold shield 5 is a T-shaped cold shield composed of an X-direction liquid nitrogen pipe coaxially arranged with the cooling jacket 1 and a Y-direction liquid nitrogen pipe perpendicular to the axial direction of the X-direction liquid nitrogen pipe. Screen.

[0033] Between the X-direction liquid nitrogen pipe and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com