Laminated electric heating auto glass with transverse transition zones

A technology for electrically heating glass and transition zones, applied in windshields, transparent/reflective heating devices, vehicle components, etc., can solve problems such as affecting the heating effect, the semi-resistance zone can only be heated, and the film layer can only be slightly heated, etc. To achieve the effect of improving the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

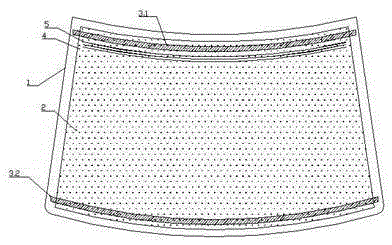

[0043] Such as figure 1 As shown, the present invention includes a glass substrate 1, and an electrically heated conductive film assembly is plated on the glass substrate 1. The electrically heated conductive film assembly is composed of a conductive film layer 2, a first bus bar 3.1 and a second bus bar 3.2. The film layer 2 is plated on the glass substrate 1, the first bus bar 3.1 and the second bus bar 3.2 are respectively connected to the upper and lower ends of the conductive film 2, and the first bus bar 3.1 and the second bus bar 3.2 are respectively arranged on the glass substrate 1. The upper edge and the lower edge; a transition area 4 is provided on the conductive film layer 2 of the glass substrate 1, and the transition area 4 is composed of several conductive transition strips 5, and the several conductive transition strips 5 are printed on the conductive film layer by silver paste 2 and / or a metal foil strip, the transition zone 4 is close to the first bus bar 3...

Embodiment 2

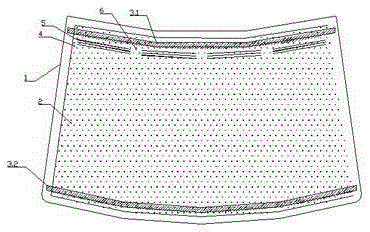

[0059] figure 2 gives something like figure 1 The structure of each group of conductive transition strips 5 is provided with gaps 6, and the gaps 6 are in the same position.

Embodiment 3

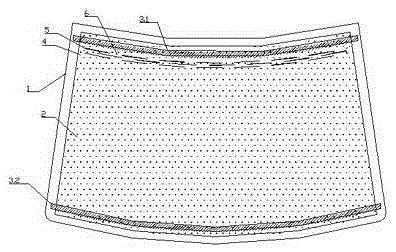

[0061] image 3 gives something like figure 1 structure, wherein the gaps 6 of the conductive transition strips 5 are arranged alternately.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com