Drafting unit having a fiber guiding element

A technology for guiding elements and fibers, used in drafting equipment, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of weakened pressing effect, complex design of fiber guiding devices, etc., and achieve the effect of reducing maintenance work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

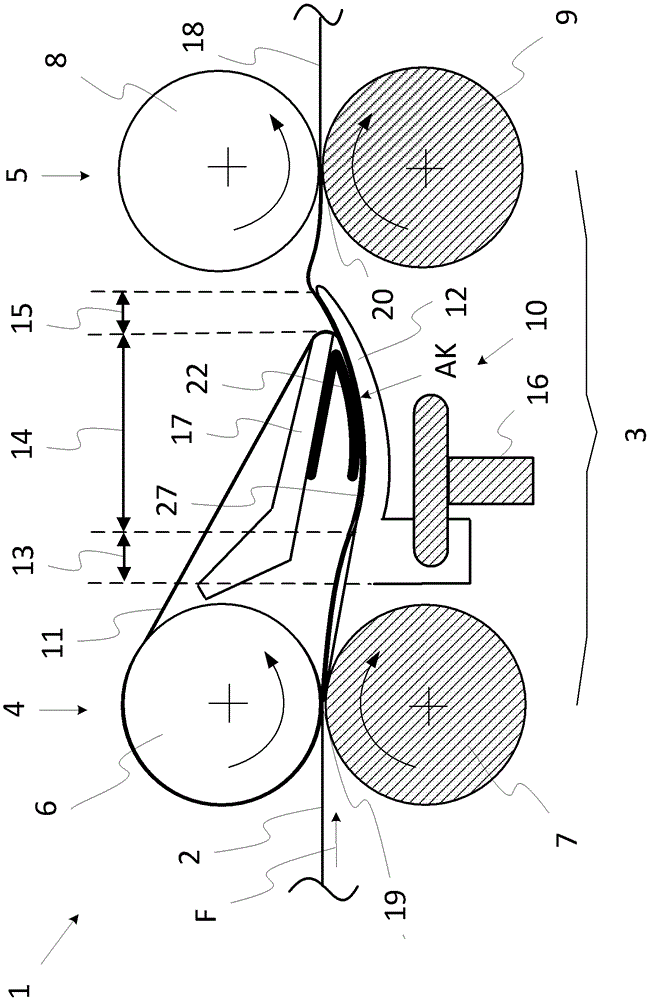

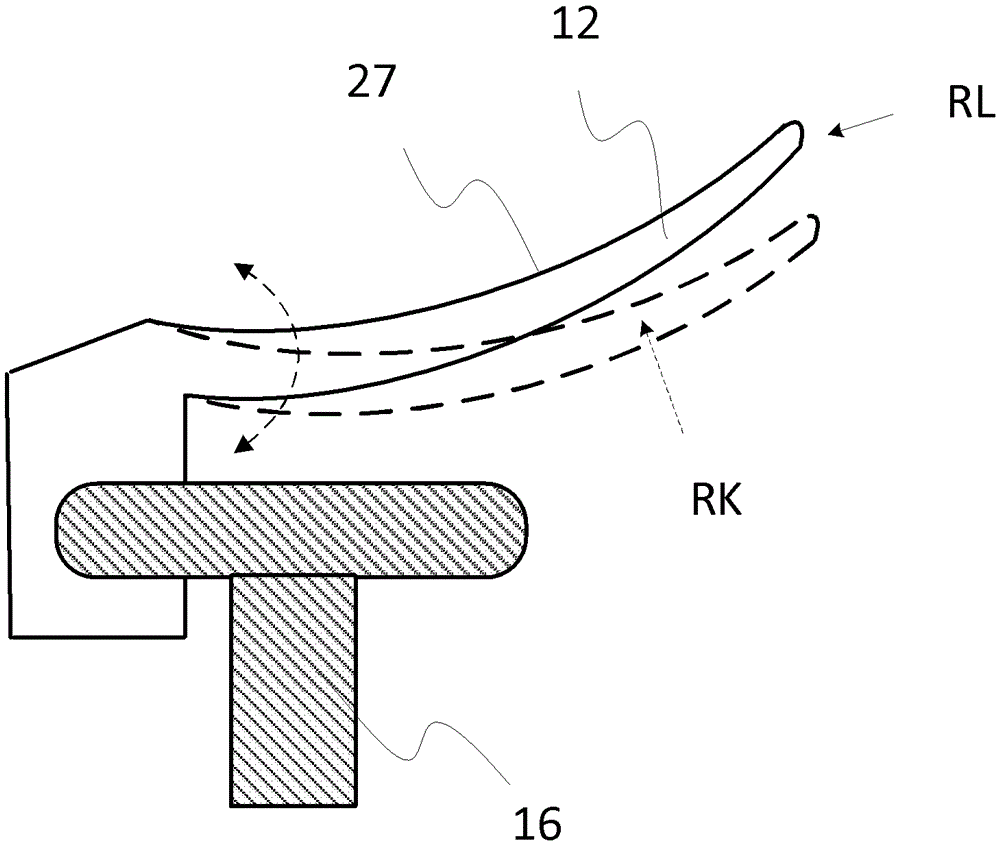

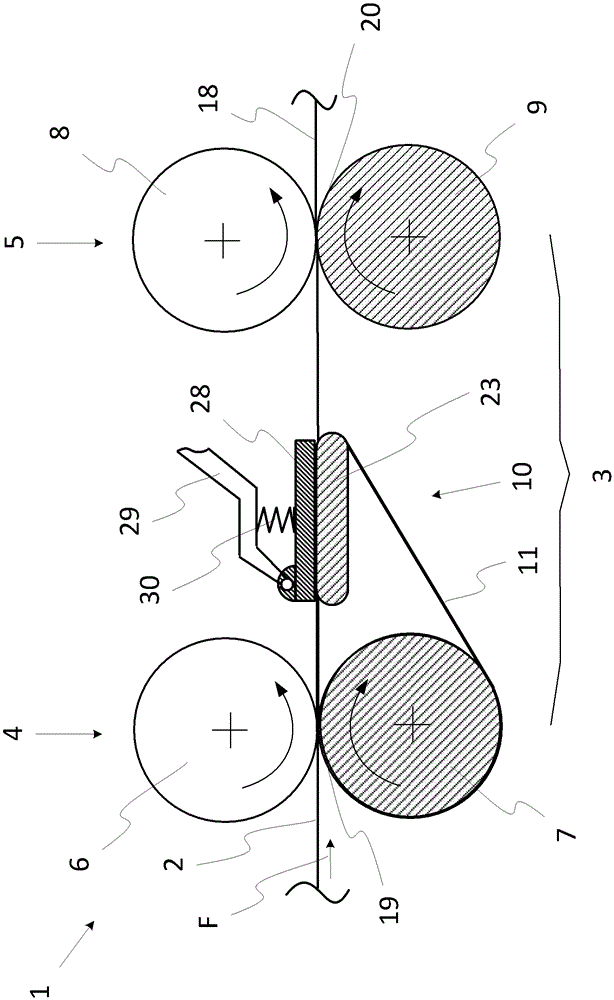

[0028] figure 1 A schematic side view of a drafting roller 1 of a spinning machine with a conventional fiber guiding device 10 (as known in the prior art) is shown. The spinning machine may in particular be a spinning preparation machine such as a flyer spindle or a draw frame or a spinning machine such as a ring spinning machine. Drafting rollers 1 are arranged to draft feed fiber bundles 2 , for example fiber slivers or rovings, in a drafting zone 3 so that a uniformly raised fiber bundle 18 is obtained. The drafting zone 3 is located between the nip line 19 of the pair of rollers 4 on the infeed end and the nip line 20 of the pair of rollers 5 on the delivery end.

[0029] Similar to the bottom roller 9 on the delivery end, the bottom roller 7 on the infeed end is mounted in a stationary support and driven. The bottom roller 7 on the infeed end is assigned to the movable and loaded top roller 6 on the infeed end so that the extracted fiber bundle 2 is clamped on the top r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com