Bulking machine for ready-to-eat fish and shrimp foods

An extruder and food technology, which is applied in the field of aquatic product processing, can solve the problems of not having fish bones and large individuals, and achieve the effects of low manufacturing cost, reduced production cost, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

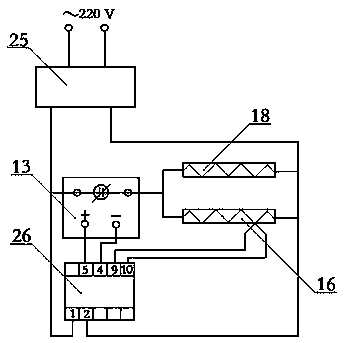

[0011] The solid state relay 13 , the lower heater 16 , the upper heater 18 , the leakage protector 25 and the intelligent temperature controller 26 in the present invention are all in the prior art, and the wiring diagram is shown in FIG. 3 , which will not be repeated here.

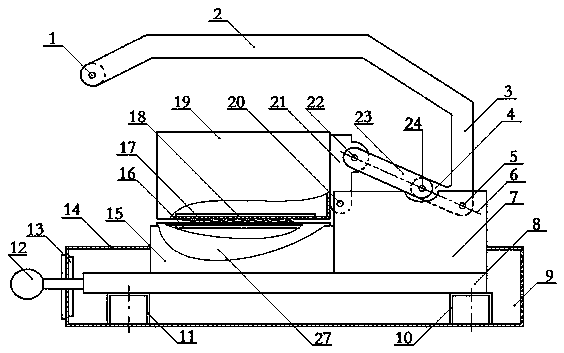

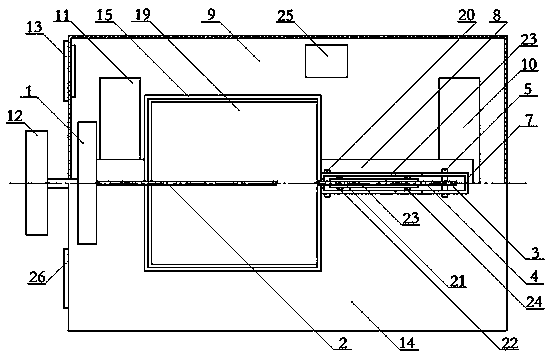

[0012] The handle 1 and the base armrest 12 can be made of materials with slow heat conduction. Rear base 10, front base 11, upper shell cover 14, load-bearing guard 15, lower pin 20 of rocking back link, 21 rocking back link, upper pin 22 of rocking back link, intermediate link 23 and pressure The pin shaft 24 of the connecting rod arm can be made of metal material, because the upper pressing block 19 and the lower pressing fast 27 are in direct contact with the fish and shrimp slices 17, so they can be made of stainless steel. The installation relationship of all components has been given in the attached drawings. One intermediate link 23 can also be used, and the geometric dimensions of the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com