Manufacturing device suitable for busbar

A technology for manufacturing devices and busbars, which is applied in the field of busbar manufacturing devices, which can solve problems such as the influence of the conductive performance of the connection surface, uneven busbar molding, and errors in lead liquid, so as to improve conductive stability and avoid lead liquid backflow , The effect of convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

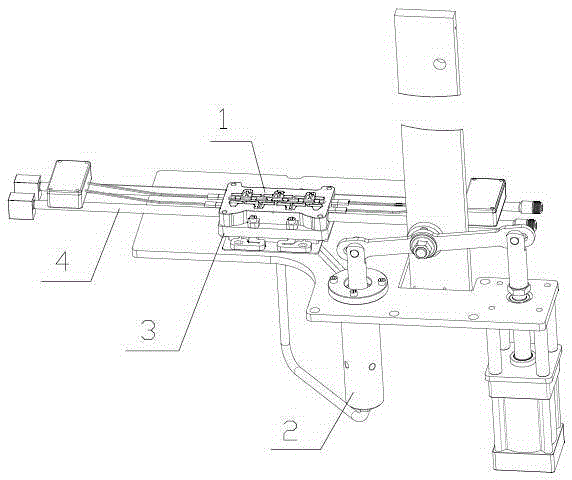

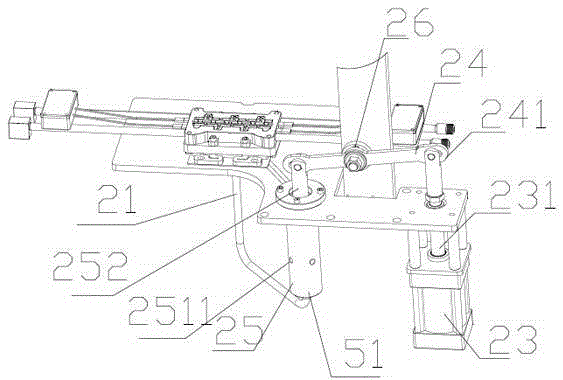

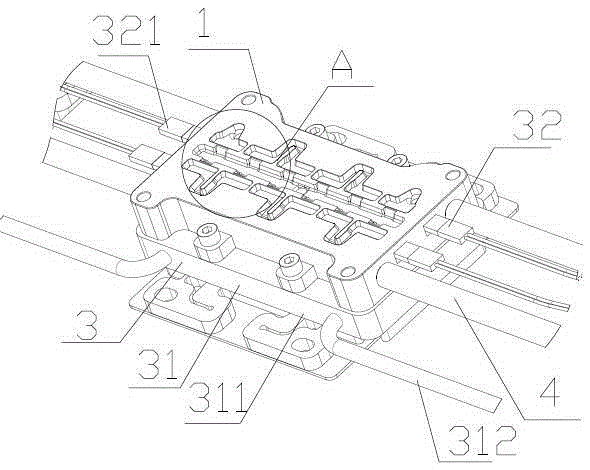

[0040] Example 1, such as figure 1 and figure 2Shown: a manufacturing device suitable for busbars, including a lead pot and a mold 1, and also includes a quantitative lead replenishing device 2 for quantitatively pressing the lead liquid in the lead pot into the mold 1, and a heating device for heating the mold 1 The heating device 3 and the cooling device 4 for cooling the mold 1, the mold 1 is located above the liquid level of the lead pot, and the mold 1 includes a base road 13 and an inlet that is opened on the base road 13 and penetrates the mold 1 downwards. Liquid port 15, a cover plate is provided on the top of the mold 1, and a forming groove is provided at the side end of the base channel 6; the quantitative lead replenishing device 2 includes an extrusion pump 25, a driving device 23 for driving the extrusion pump 25, and a connection between the liquid inlet 15 and the The guide pipe 21 of the squeeze pump 25 is provided with a liquid inlet hole 2511 for the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com