Large-diameter internal gear broaching tool with long rear handle

A large-diameter, internal gear technology, applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., can solve problems such as safety production accidents, broach breakage, broach scrapping, etc., and achieve safety Guarantee, reduce the use of materials, and reduce the effect of tool manufacturing costs

Active Publication Date: 2016-03-02

EST TOOLS

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

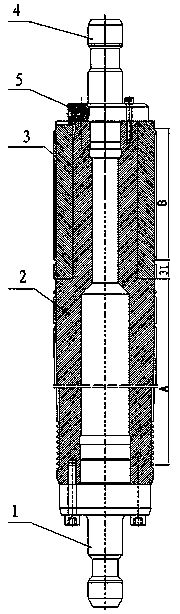

However, since the fine-drawing and expanding gear sleeve 3 is arranged on the outer wall of the rear end of the rough broach body 2, there is a large diameter drop in the front and rear sections of the rough broach body 2 regardless of the outer circle or the inner hole. During the heat treatment and quenching process due to temperature changes The stress concentration at the step caused by asynchrony is prone to quenching cracks or potential hidden dangers of broach breakage caused by stress release during application, which will inevitably cause losses such as scrapping of the broach and damage to the machine tool. What is more serious may be caused by this Causing production safety accidents

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

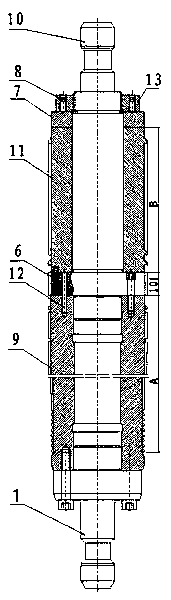

The invention discloses a large-diameter internal gear broaching tool with a long rear handle. The large-diameter internal gear broaching tool with the long rear handle comprises a front handle, a rough broaching tool body, a finish broaching and tooth expanding tool sleeve and the rear handle. The rear handle is lengthened. The rough broaching tool body is in the shape of a straight cylinder. The front handle and the rear handle are fixedly connected to the two ends of the rough broaching tool body respectively. The outer wall of the rear handle is sleeved with the finish broaching and tooth expanding tool sleeve. The rough broaching tool body and the rear handle are limited in the circumferential direction through cylindrical pins. The finish broaching and tooth expanding tool sleeve and the rear handle are limited in the circumferential direction through a flat key. By the adoption of the tool, the potential hidden danger that the tool is broken can be completely avoided when the tool is applied to heat treatment quenching and broaching, it can be guaranteed that the process is safe, and the existing precision and performance of the tool are guaranteed.

Description

technical field The invention relates to a large-diameter internal gear broach with a long back shank structure, in particular to a large-diameter internal gear broach in the form of a structure in which a fine-drawing and expanding gear sleeve is directly installed on the outer wall of the broach back shank. Background technique Compared with traditional processing techniques such as gear shaping, large-diameter internal gear broaching has become the mainstream manufacturing process choice in mass production due to its extremely high production efficiency. Large-diameter internal gear broaches generally have an outer circle of more than 200mm. In order to improve the heat treatment hardenability of the broach and reduce the self-weight of the broach, the broach body is usually hollow, and the broach generally adopts an assembled structure, as shown in Figure 1, consisting of the front handle 1, the gradually formed rough broach body 2, and the same Contour-type fine-drawin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23F21/26

Inventor 何勤松陈子彦杨益波孙洪卫顾拥民

Owner EST TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com