Steel bar eccentric connection half grouting sleeve and using method thereof

A technology of semi-grouting sleeves and steel bars, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems that have not been effectively solved, the increase of the concrete protective layer, and the impact on the quality of the project, so as to achieve convenient connection and improvement Anti-seismic energy dissipation capacity and the effect of improving project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

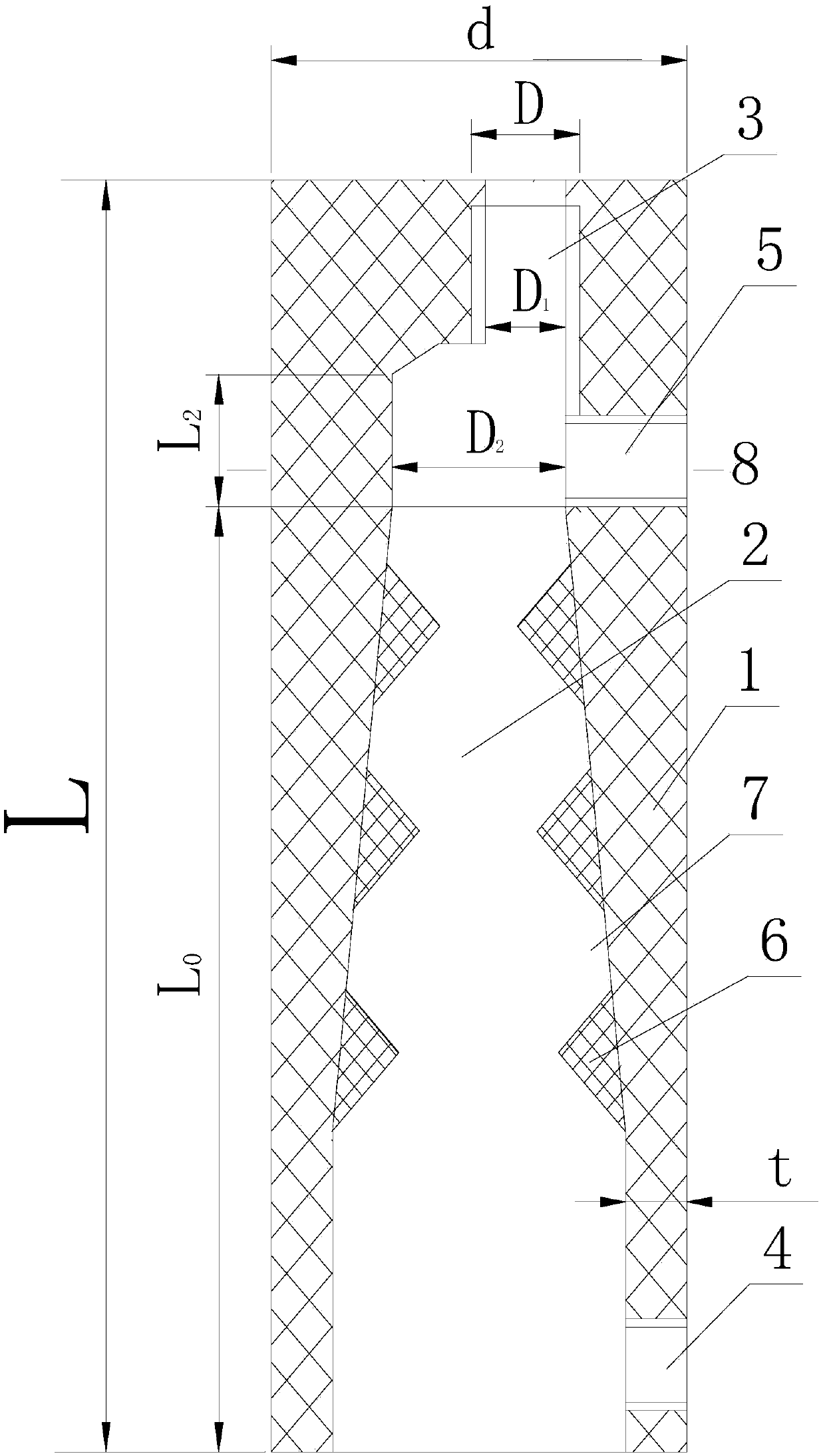

[0019] Such as figure 1 As shown, a semi-grouting sleeve for eccentric connection of steel bars includes a sleeve body 1 with a grouting hole 4 and a grouting hole 5, a threaded hole 3 is provided on the upper part of the sleeve body 1, and a lower internal cylinder 2, the threaded hole 3 is in communication with the lower inner cylinder 2; The inner surface of the inner surface is provided with barbs 6, and the barbs 6 make it difficult to pull out after the steel bar and the sleeve body 1 are connected by high-strength grouting material, which improves the connection performance of the steel bar sleeve. The barbs 6 are raised ring-shaped structures with reduced diameters arranged at regular intervals on the inner surface of the lower inner cylinder 2, with their tips facing the inside of the cylinder and capable of resisting the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com