An aluminized steel transmission tower

A technology of transmission towers and aluminized steel, applied in towers, solid diffusion coatings, coatings, etc., can solve the problems of transmission tower materials and energy waste, increase construction difficulty, poor performance of transmission tower anti-dancing devices, etc., to achieve Avoid economic loss and social impact, fast pickling and rust removal, and improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

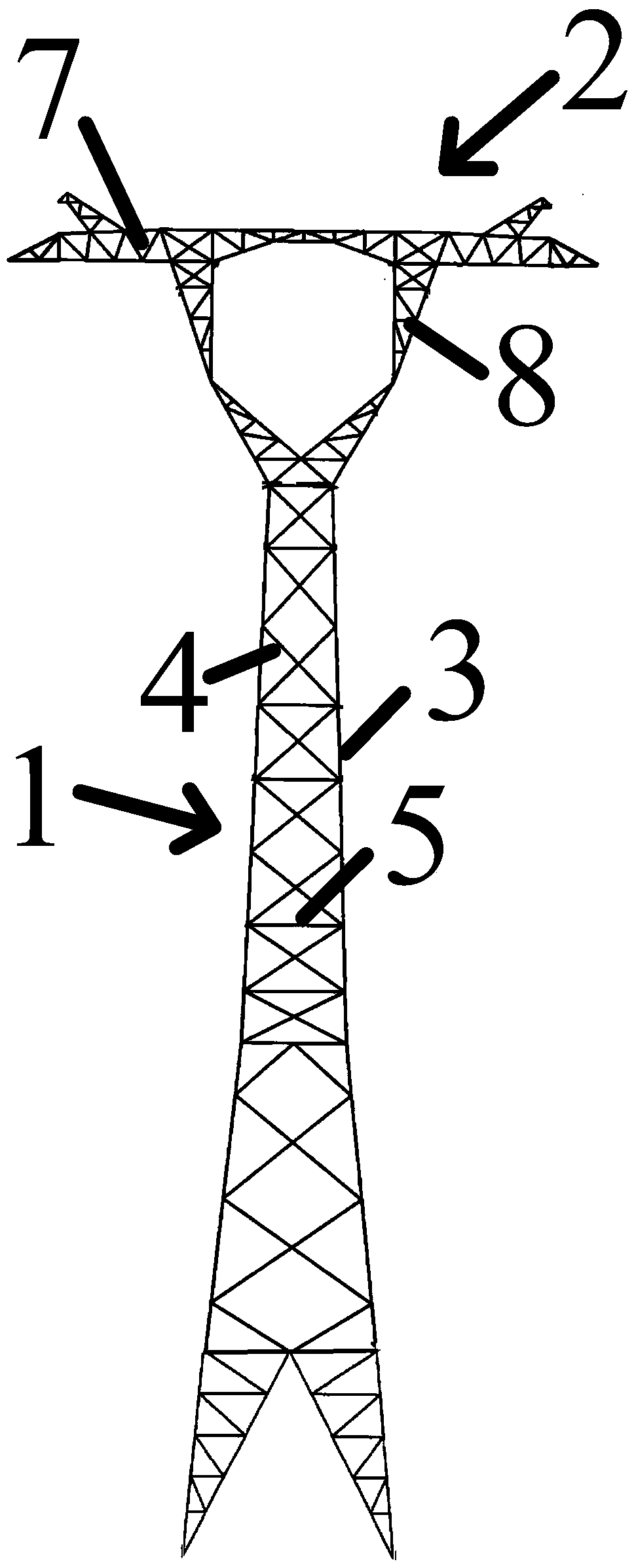

[0054] Such as figure 1As shown, an aluminized steel transmission tower, the transmission tower includes a vertically arranged tower body 1, a tower head 2 arranged horizontally on the upper end of the tower body 1, and a transmission wire arranged on the tower head 2,

[0055] The tower body 1 is a frame structure formed by staggered connection of angle steel main material 3, angle steel oblique material 4 and angle steel horizontal material 5 vertically arranged with the angle steel main material 3;

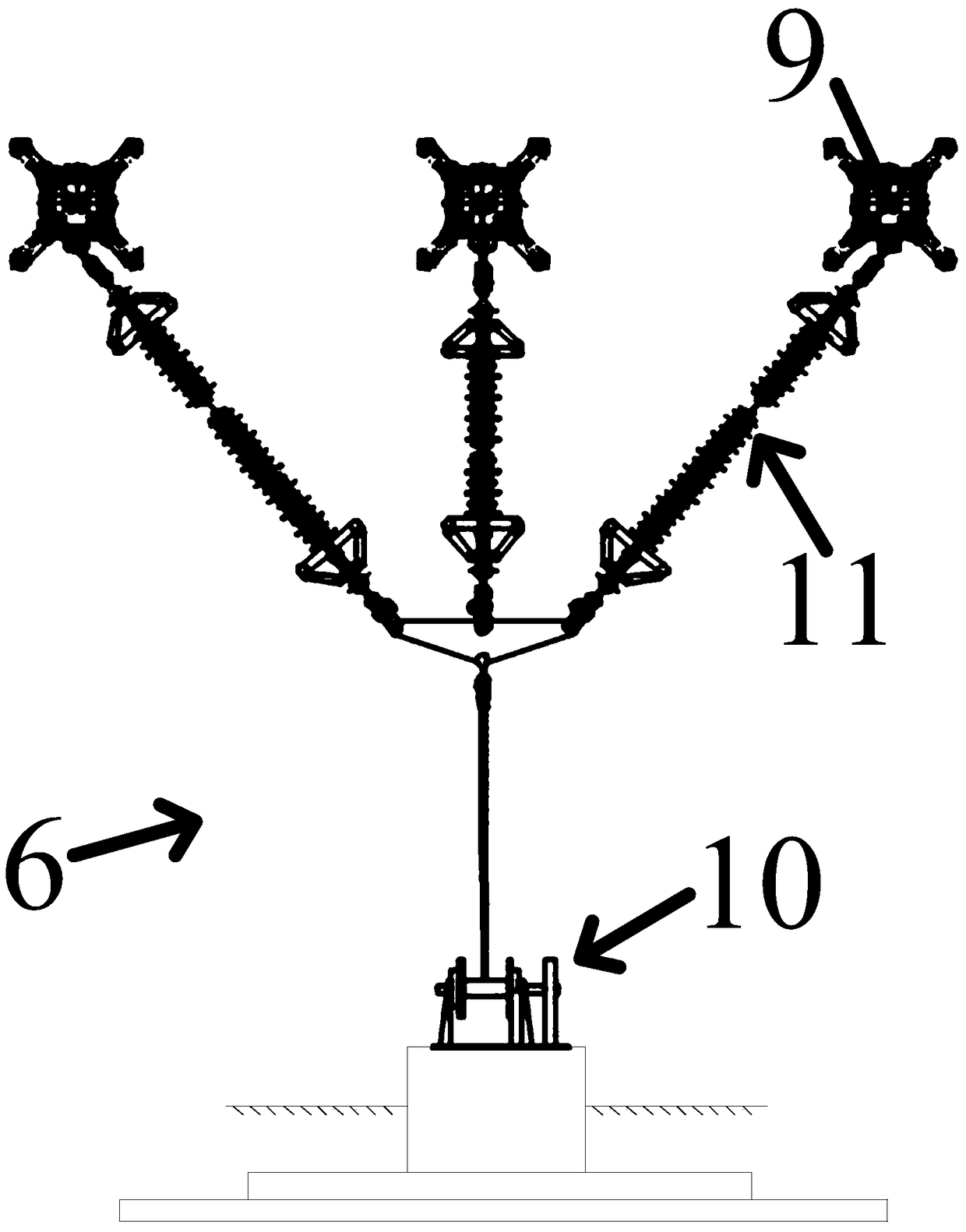

[0056] The wire dance prevention device 6 is provided on the power transmission wire.

[0057] The tower head 2 includes a horizontal cross arm 7, and support vertical beams 8 symmetrically arranged on both sides of the tower body 1 perpendicular to the cross arm 7;

[0058] The supporting vertical beam 8 and the cross arm 7 encircle a tower window shaped as a hexagon;

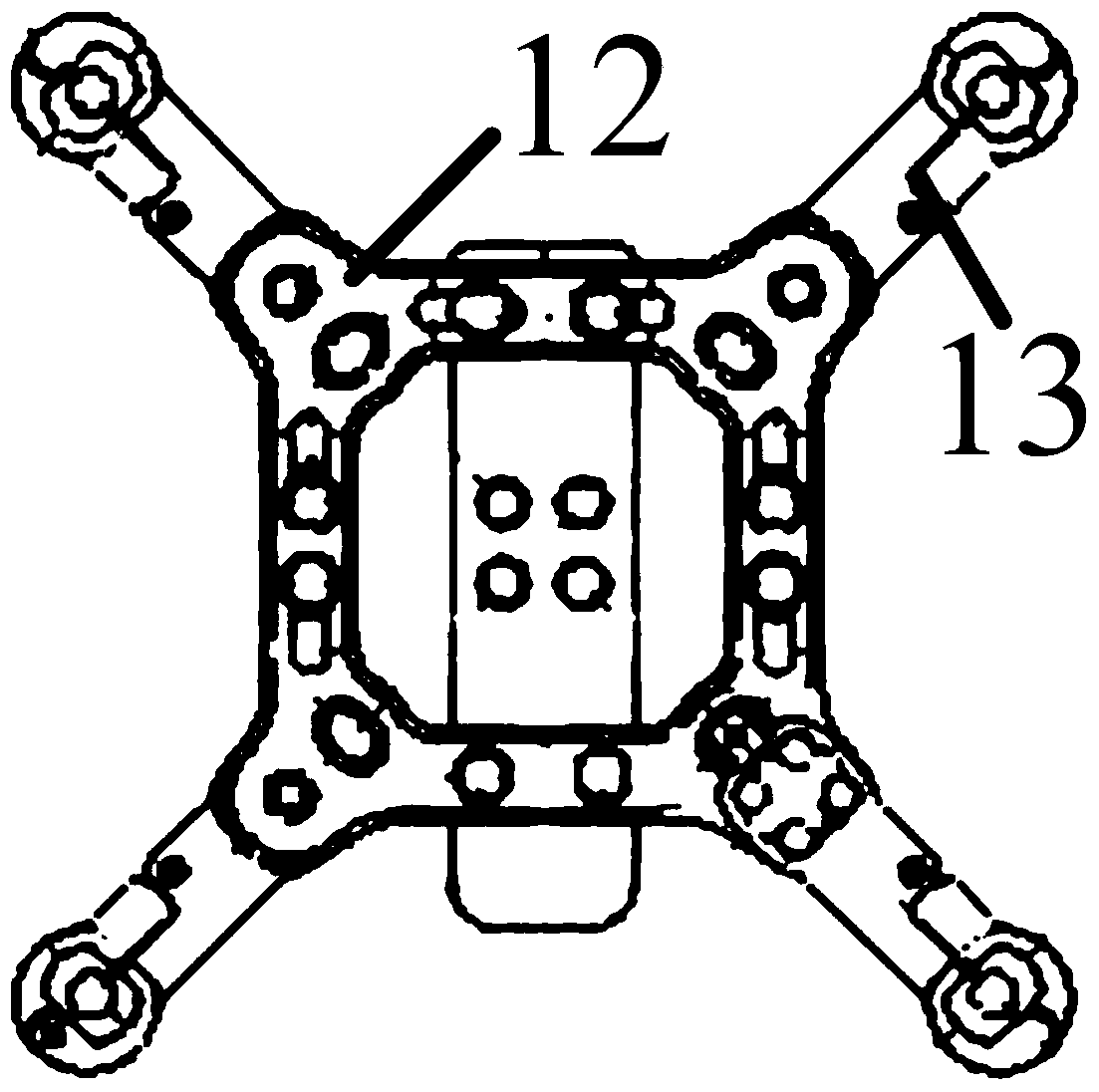

[0059] The left end, the middle end and the right end of the cross arm 7 are respectively provided with co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com