A manufacturing method for a new type of pipe section used for seawater lifting of offshore oil platforms

A seawater lifting and offshore oil technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of inability to meet the working requirements of seawater lifting pumps, high cost of high-nickel alloy pipelines, and unbearable platforms. Light weight, low cost, seawater corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

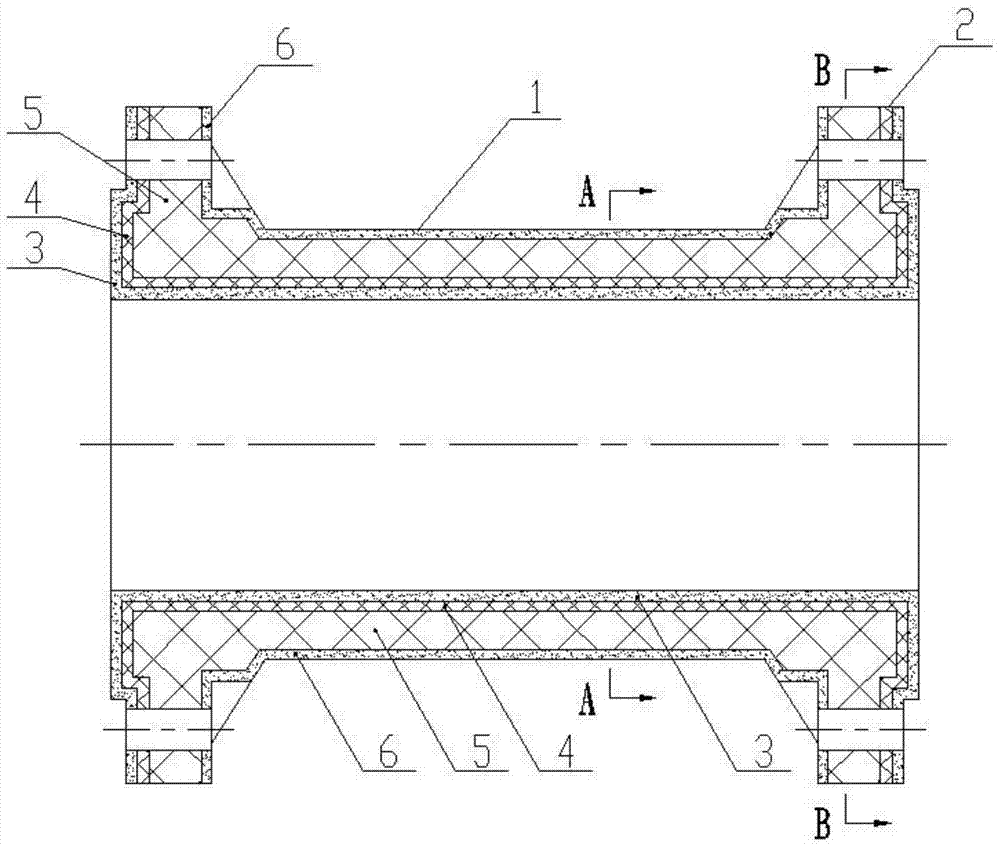

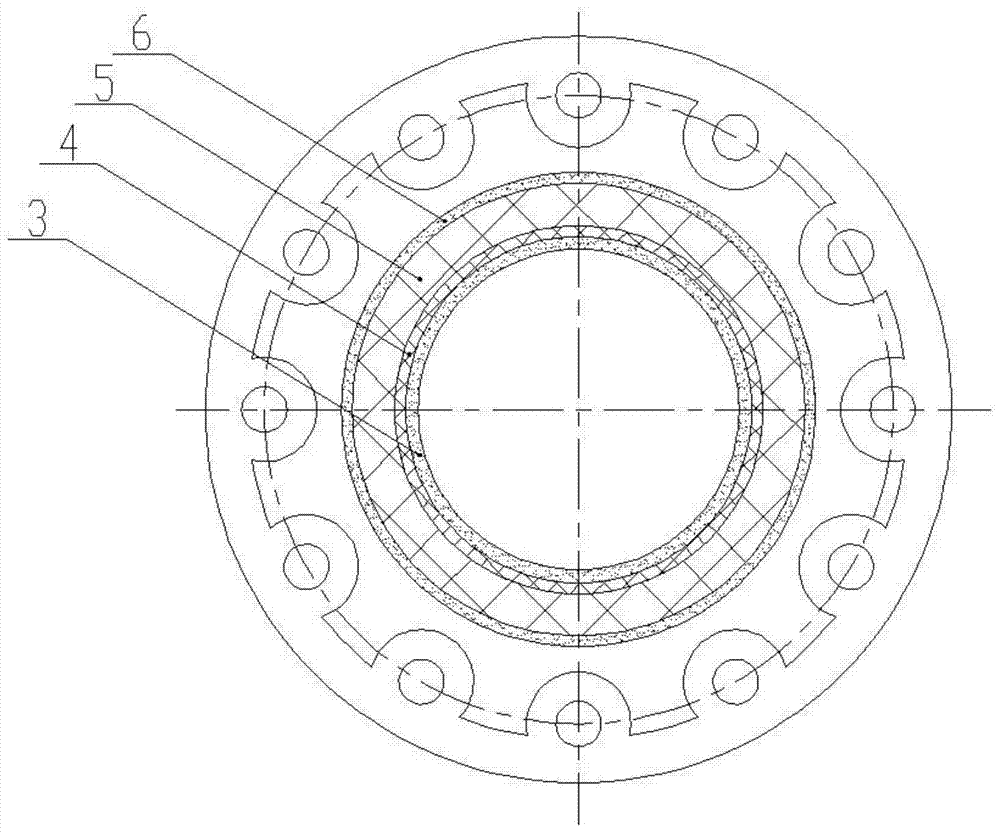

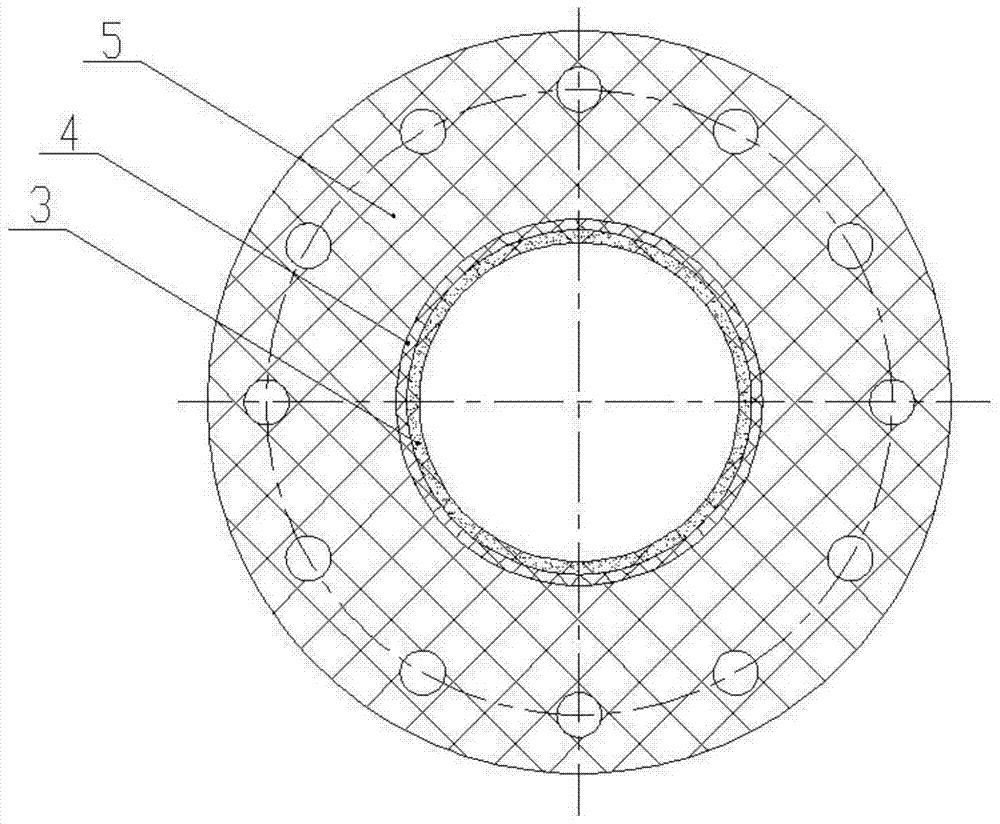

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] as attached Figures 1 to 3 As shown, a new type of pipe section used for lifting seawater on an offshore oil platform includes a pipe body 1 and flanges 2 arranged at both ends of the pipe body 1. The pipe body 1 and the flange 2 are integrally formed; the pipe body 1 and flange 2 are formed by one-time winding of carbon fiber and combined with resin curing; the pipe body 1 and flange 2 include: an inner lining layer 3 made of polyester film, and the surface of the inner lining layer 3 is sprayed with resin Layer 4, the inner lining layer 3 sprayed with the resin layer 4 is wound with a carbon fiber resin composite layer 5 along the axial direction and longitudinal direction of the pipeline, and the surface of the carbon fiber resin composite layer 5 is provided with a polyester film layer 6 . The size of the pipe body 1 can be customized according to actual r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com