Preparation device for liquefied natural gas

A technology for liquefied natural gas and a preparation device, which is applied in the field of liquefied natural gas preparation devices, can solve the problems of large liquefaction capacity, large investment in facilities, long cycle, etc., and achieves the effects of low cost, small investment and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

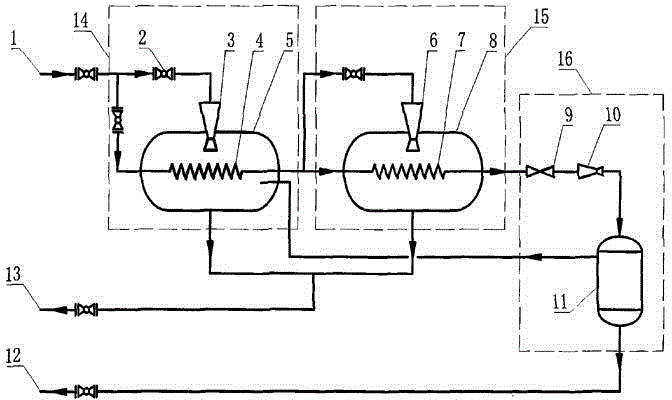

[0010] like figure 1 As shown, a liquefied natural gas preparation device of the present invention is composed of a primary heat exchange system 14, a secondary heat exchange system 15 and an expansion refrigeration system 16; the primary heat exchange system 14 includes a primary refrigerator 3, a primary The heat exchange tube 4 and the primary heat exchanger body 5, the compressed natural gas inlet pipeline 1 is respectively connected with the primary refrigerator 3 and the primary heat exchange tube 4 through pipelines, and a valve 2 is provided on the pipeline, that is, the compressed natural gas is passed through the inlet 1 The valve 2 and the pipeline enter the primary heat exchanger system 14 in two streams, one stream enters the primary refrigerator 3, and the other stream enters the primary heat exchange tube 4 for the first cooling; the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com