Briquette burning device

A technology of a combustion device and briquettes, which is applied in the field of combustion furnaces, can solve the problems that heat cannot be effectively utilized, increase the usage of briquettes, etc., so as to achieve the effects of improving utilization efficiency and prolonging combustion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

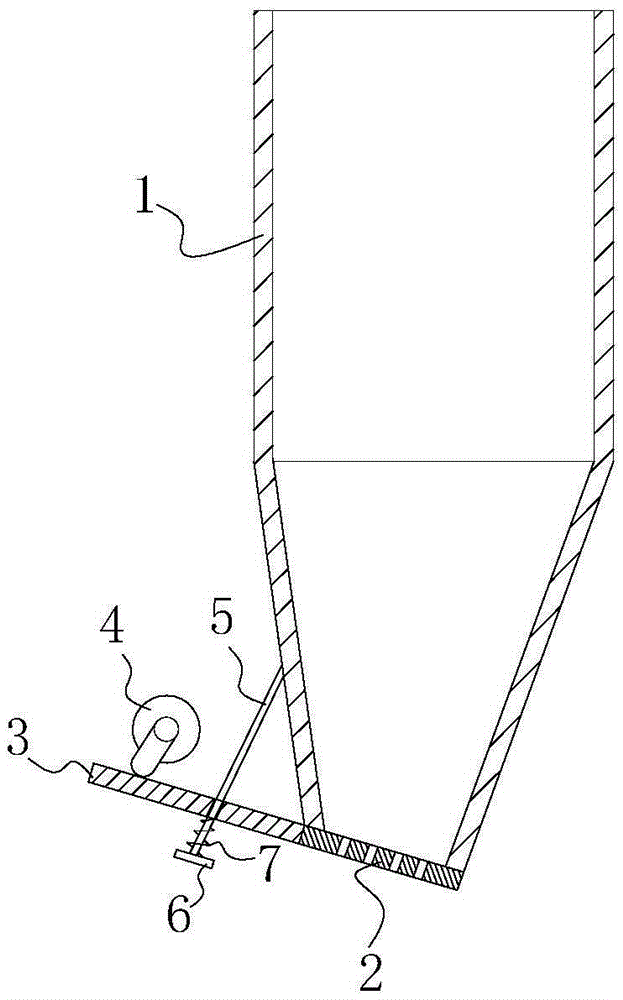

[0011] Such as figure 1 As shown, the briquette burning device of the present invention includes a coal furnace 1 with an internal combustion chamber, a coal outlet communicating with the internal combustion chamber of the coal furnace 1 is provided at the bottom of the coal furnace 1, and a sieve plate is arranged at the coal outlet 2. The sieve plate 2 is provided with a plurality of fine holes, and one end of the sieve plate 2 is fixedly connected with a vibrating plate 3 , and a vibrator 4 is arranged on the vibrating plate 3 . During work, briquettes are added into the combustion chamber of coal furnace 1, and a large amount of coal ash can be brought in in this process. At this time, turn on the vibrator 4 to make the vibrator 4 drive the vibrating plate 3 to vibrate. Since the vibrating plate 3 is fixedly connected to one end of the sieve plate 2, it drive...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap