Gain measuring device and method of cascaded micro channel plate

A technology of microchannel plate, measuring method, applied in the direction of measuring device, measuring electricity, measuring electric variable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

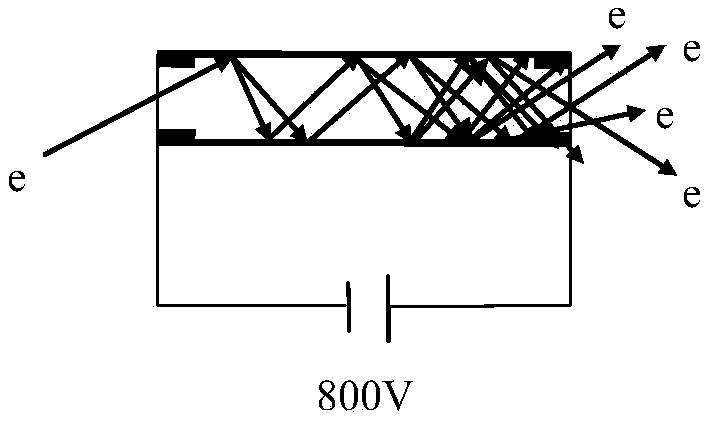

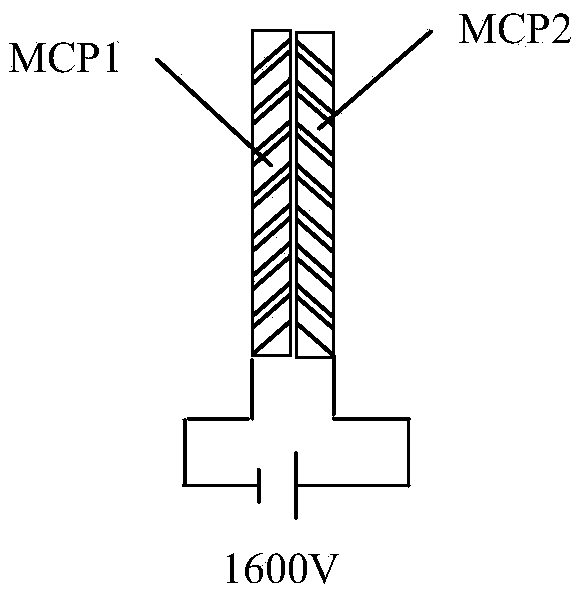

[0064] Gain of two cascaded MCPs

[0065] The measurement is carried out in a dark room at a temperature of 21-25°C. The measured cascaded MCP has an effective working diameter of Φ18mm, an outer diameter of Φ25mm, and a channel diameter of Φ6μm, which are MCPs used in conventional image intensifiers.

[0066] Put the output end of the first MCP and the input end of the second MCP close together, then put it into a special measurement fixture and put it into the MCP gain measurement device. The fixture used is a common MCP measurement fixture.

[0067] Close the baffle, insert the UV neutral density filter, start the vacuum system of the equipment, and start vacuuming. When the vacuum degree of the measurement system reaches 5×10 -5 After lifting, turn on the high-voltage power supply and apply the required working voltage to the measured MCP, photocathode and fluorescent screen; the input voltage of the first MCP is -1600V, the output voltage of the second MCP is zero potenti...

Embodiment 2

[0080] Gain of three cascaded MCPs

[0081] The measurement is carried out in a dark room at a temperature of 21-25°C. The measured MCP has an effective working diameter of Φ18mm, an outer diameter of Φ25mm, and a channel diameter of Φ6μm, which is the MCP used in conventional image intensifiers.

[0082] Put the output end of the first MCP close to the input end of the second MCP, then put the output end of the second MCP close to the input end of the third MCP, then put it into the special measuring fixture and place it into the MCP gain measurement device. The fixture used is a common MCP measuring fixture.

[0083] Close the baffle, insert the UV neutral density filter, start the vacuum system of the equipment, and start vacuuming. When the vacuum degree of the measurement system reaches 5×10 -5 After Torr, turn on the high-voltage power supply, and apply the required operating voltage to the three cascaded MCPs, photocathode and phosphor screen to be measured. The inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com