High-density low-cost magnetic recording medium FeNi alloy and preparation method therefor

A magnetic recording medium, a low-cost technology, applied in the field of information storage, can solve the problems of late start of research and low alloy magnetite, and achieve the effect of reducing material cost and increasing saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Provide a high-density low-cost magnetic recording medium alloy L1 0 -The preparation method of FeNi, comprises the steps:

[0034] (1) Prepare the seed layer: vacuumize the magnetron sputtering equipment to reduce the background pressure of the sputtering chamber to less than 1×10 -8 Torr, use argon as the working gas, keep the sputtering pressure at 4.0-9.0mTorr, open the baffle of the Fe target, deposit a layer of Fe film with a thickness of 1-2nm on the (001) MgO substrate, and close the Fe target material baffle;

[0035] (2) Prepare the buffer layer: Then, without changing the sputtering conditions, open the baffle of the Au target, continue to deposit the Au film on the Fe film, with a thickness between 40-50nm, and close the baffle of the Au target;

[0036] (3) Preparation of FeNi film: without changing the sputtering conditions, heat the substrate to between 400-450°C, open the baffles of the Fe target and the Ni target at the same time, and molecularly The F...

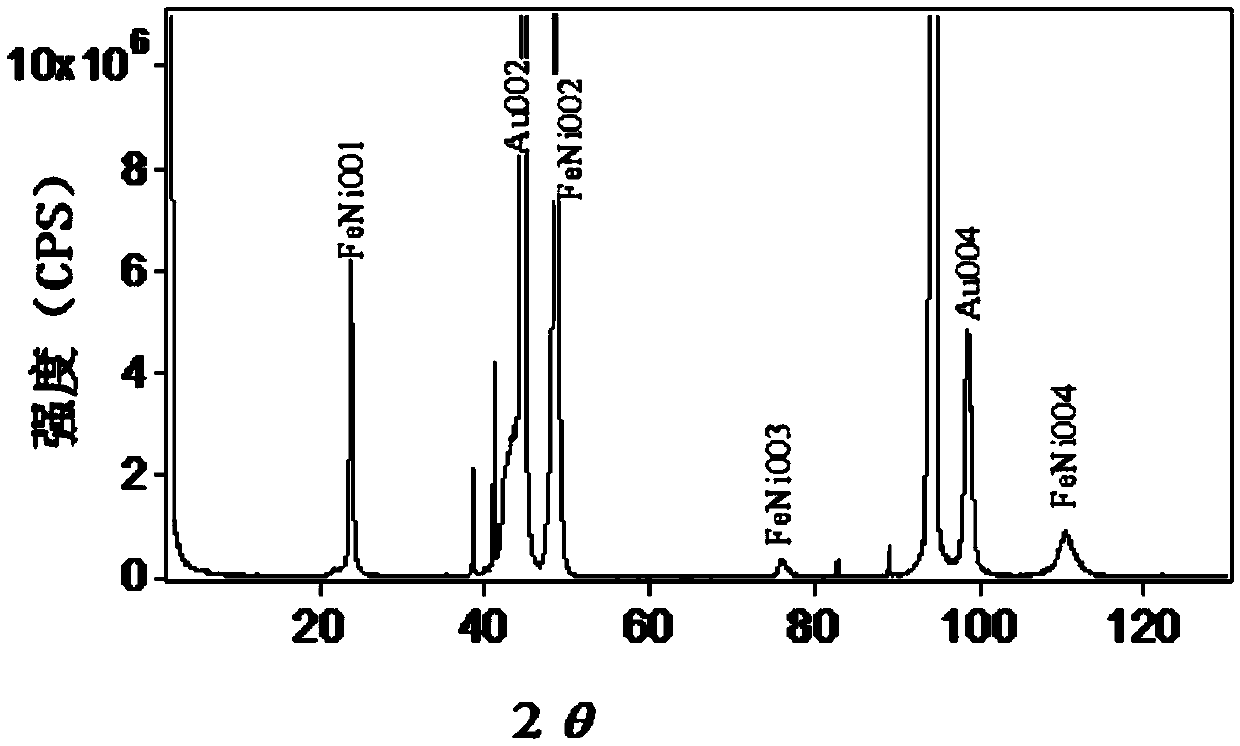

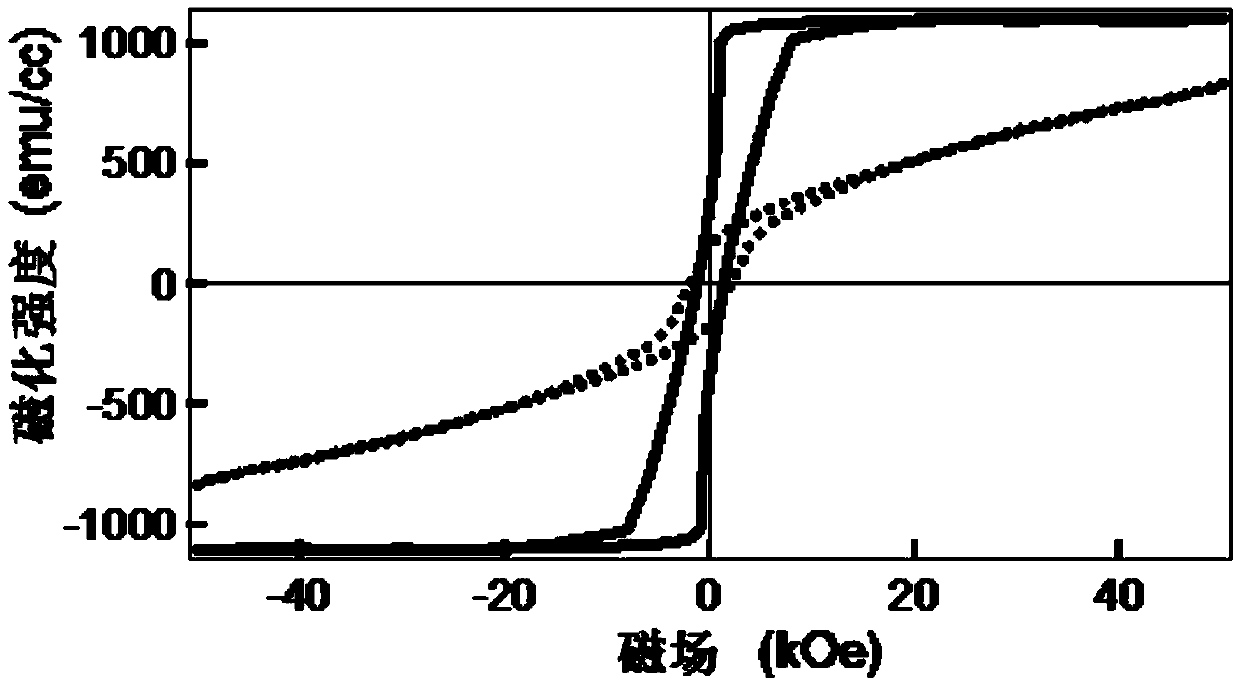

Embodiment 1

[0040] Embodiment 1-Fe (1nm) / Au (40nm) / FeNi (50nm) film

[0041] (1) Prepare the seed layer: use (001) single crystal MgO as the substrate, after careful cleaning, put it into the sputtering chamber, and vacuum the chamber to 2×10 -9 Torr, using argon as the working gas, keeping the sputtering pressure at 5mTorr, opening the baffle of the Fe target, depositing a layer of Fe film with a thickness of 1nm on the (001) MgO substrate, and closing the baffle of the Fe target;

[0042] (2) Prepare the buffer layer: then, without changing the sputtering conditions, open the Au target baffle, continue to deposit the Au film on the Fe film, with a thickness of 40nm, and close the Au target baffle;

[0043] (3) Preparation of FeNi film: without changing the sputtering conditions, heat the substrate to 400°C, open the baffles of the Fe target and the Ni target at the same time, and grow on the Au film by molecular beam epitaxy Deposit FeNi layer with a thickness of 50nm;

[0044] (4) An...

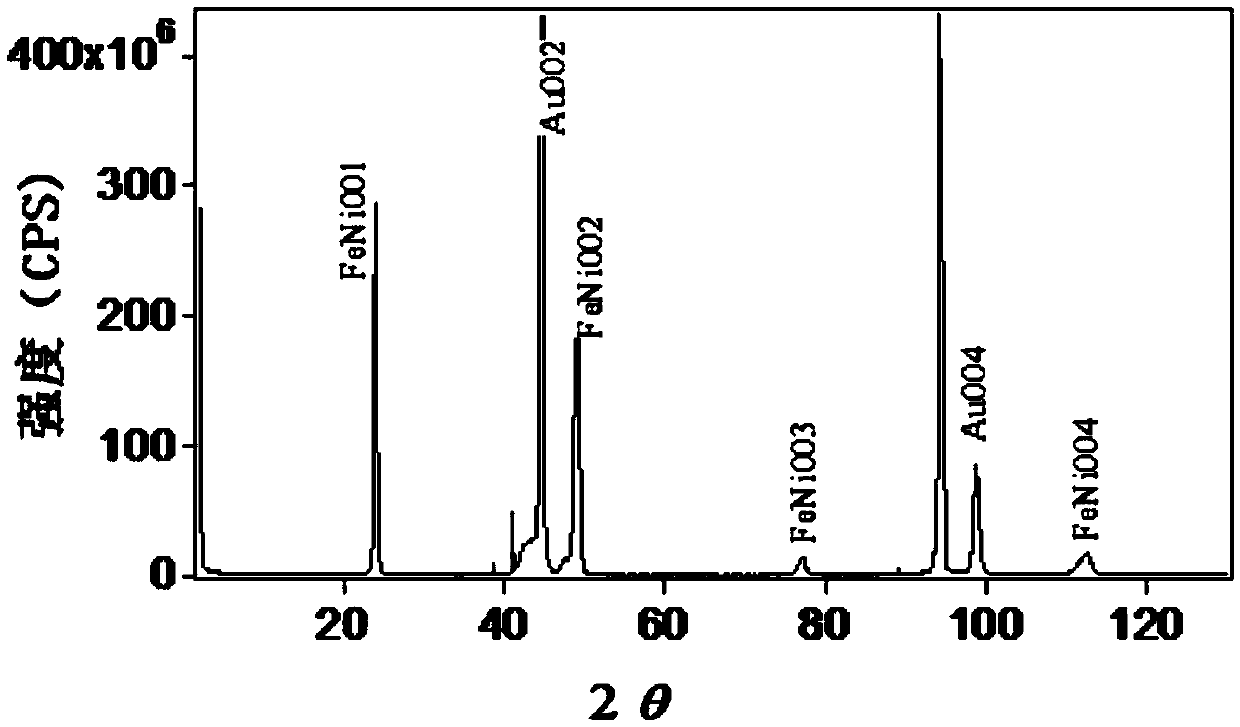

Embodiment 2

[0046] Embodiment 2-Fe (2nm) / Au (45nm) / FeNi (60nm)

[0047] (1) Prepare the seed layer: use (001) single crystal MgO as the substrate, after careful cleaning, put it into the sputtering chamber, and vacuum the chamber to 1×10 -9 Torr, using argon as the working gas, keeping the sputtering pressure at 6mTorr, opening the baffle of the Fe target, depositing a layer of Fe film with a thickness of 2nm on the (001) MgO substrate, and closing the baffle of the Fe target;

[0048] (2) Prepare the buffer layer: then, without changing the sputtering conditions, open the Au target baffle, continue to deposit the Au film on the Fe film, with a thickness of 45nm, and close the Au target baffle;

[0049] (3) Preparation of FeNi film: without changing the sputtering conditions, heat the substrate to 450°C, open the baffles of the Fe target and the Ni target at the same time, and grow on the Au film by molecular beam epitaxy Deposit FeNi layer with a thickness of 60nm;

[0050] (4) Anneali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com