Straw mulching ridge seeder

A seeder and straw technology, which is applied in the direction of agricultural machinery and equipment, agricultural machinery and implements, shovels, etc., can solve the problems of increasing costs, increasing the depth of sowing, wasting power, etc., and achieve the effects of saving costs, reducing rolling and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The utility invention will be further described below in conjunction with the accompanying drawings and embodiments.

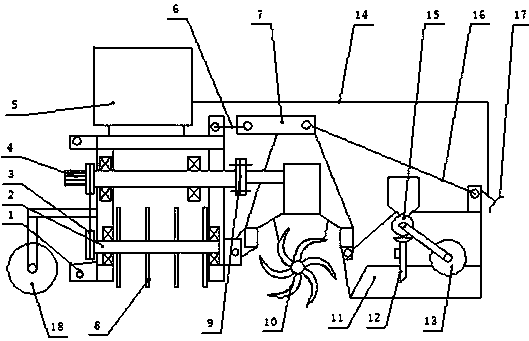

[0024] Such as figure 1 As shown, the straw-covered ridge seeder includes a straw-covered ridge-planter frame 1, a power transmission device located at the front end of the straw-covered ridge-planter frame 1, and a rotating shaft located in the middle of the straw-covered ridge-planter frame 1. Tiller frame 7 and the spraying device and seeding device located at the rear of the straw-covered ridge seeder frame (1), characterized in that the sowing device includes a ridging device (11), a sowing opener 12 , suppressing wheel 13 and seeder 15, described seeding ditch opener 12 is positioned at the ridge surface in the middle of two ridging devices 11, can be adjusted up and down to adapt to sowing depth, seeder 15 is positioned at the top of sowing ditch opener 12, by suppressing wheel 13 is driven to rotate to realize sowing. The pressing wheel 13 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com