A blending treatment system for coal mine exhaust air and gas drainage

A treatment system and gas technology, applied in the direction of gas discharge, gas treatment, auxiliary pretreatment, etc., can solve the problems of exacerbating air pollution, greenhouse effect, waste of non-renewable resources, etc., and achieve the goal of increasing operation resistance and burden and reducing operation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

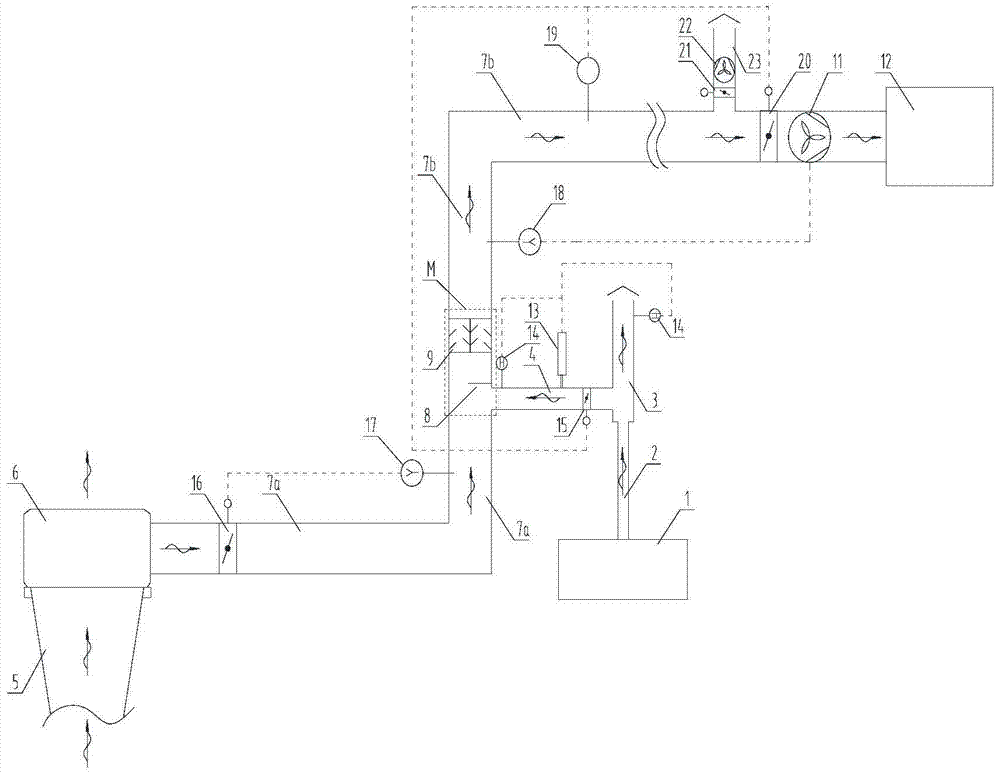

Embodiment 1

[0077] Such as figure 1 As shown, it is a blending treatment system for coal mine exhaust air and low-concentration gas drainage of the present invention. The blending treatment system includes: exhaust air induction hood 6, exhaust air conveying pipeline 7a, and drainage gas connection pipeline 4 , mixer M, mixed gas delivery pipeline 7b, induced draft fan 11 and regenerative high-temperature oxidation device 12; the said exhaust air delivery pipeline 7a is communicated with the exhaust air induction hood 6, so that the exhaust air is absorbed to the exhaust air conveying due to the negative pressure In the pipeline 7a; the exhaust port of the exhaust gas connecting pipeline 4 communicates with the exhaust air conveying pipeline 7a, so that the drained gas is input from the exhaust gas connecting pipeline 4 to the exhaust air conveying pipeline 7a, and is connected with the exhaust air conveying pipeline 7a The flowing exhaust air is mixed uniformly by the mixer M until the m...

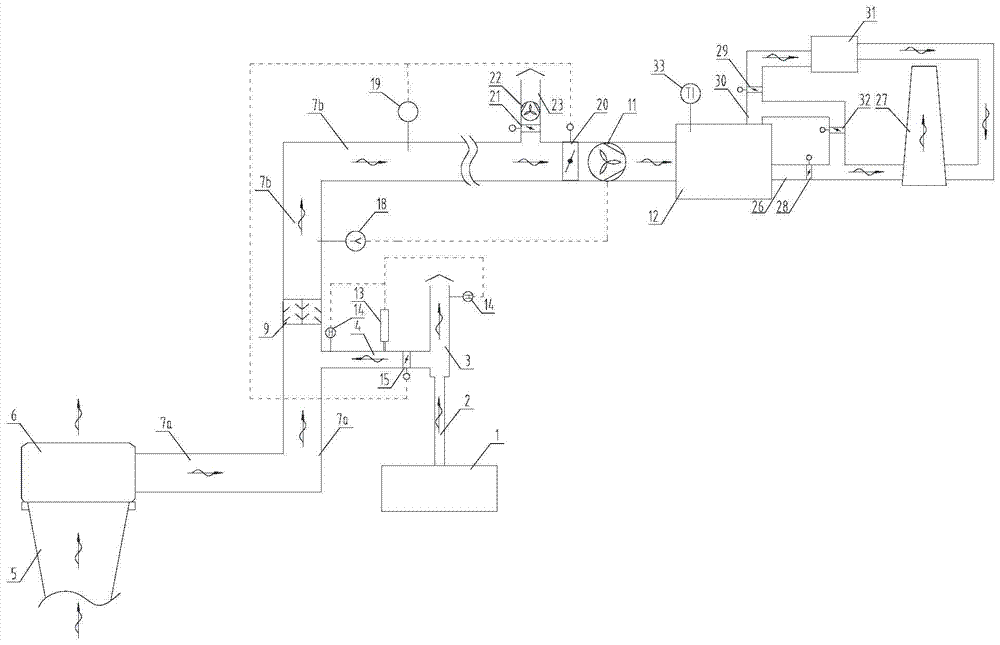

Embodiment 2

[0093] Such as figure 2 As shown, it is a blending treatment system for coal mine exhaust air and low-concentration gas drainage of the present invention. The blending treatment system includes: exhaust air induction hood 6, exhaust air conveying pipeline 7a, and drainage gas connection pipeline 4 , mixer, mixed gas delivery pipeline 7b, induced draft fan 11 and regenerative high temperature oxidation device 12. The difference from Embodiment 1 is that it also includes a chimney 27 and a steam boiler 31, and the chimney 27 communicates with the regenerative high-temperature oxidation device 12 through the provided clean gas delivery pipeline 26 for converting the regenerative high-temperature oxidation The clean gas produced by the oxidation treatment of the device 12 is discharged into the atmosphere; the clean gas delivery pipeline 26 is provided with a clean gas valve 28 for controlling the opening and closing of the clean gas delivery pipeline 26 . Both the steam boiler ...

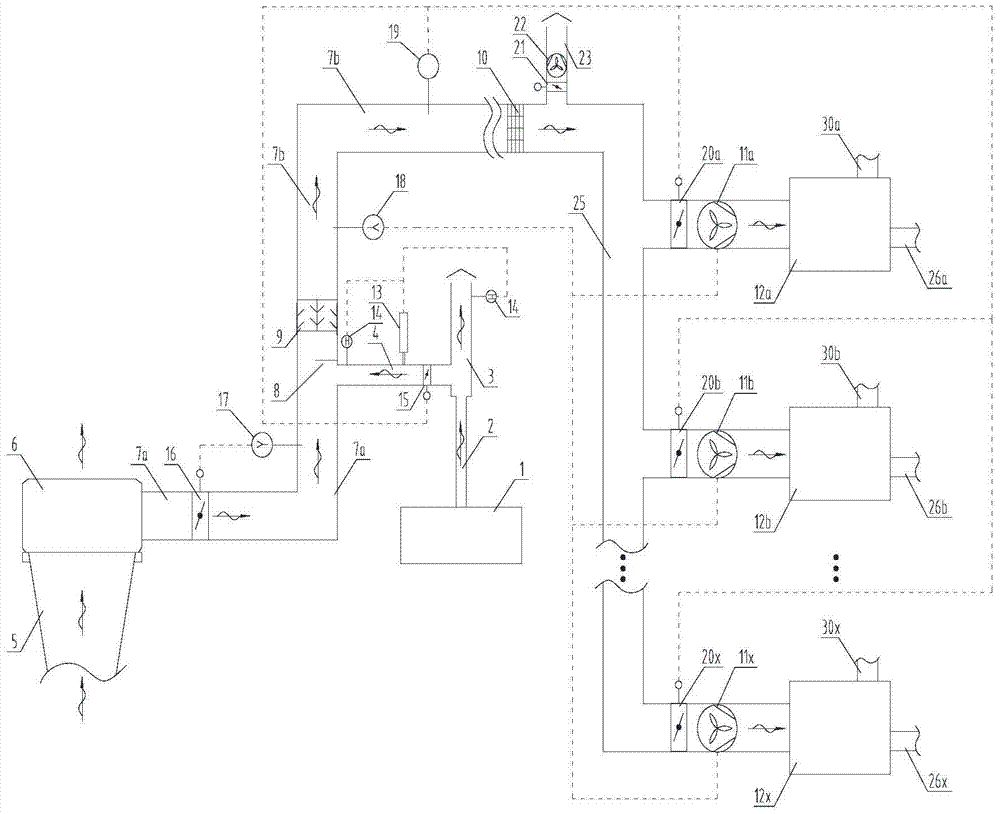

Embodiment 3

[0097] Such as image 3 As shown, it is a blending treatment system for coal mine exhaust air and low-concentration gas drainage of the present invention. The blending treatment system includes: exhaust air induction hood 6, exhaust air conveying pipeline 7a, and drainage gas connection pipeline 4 , mixer, mixed gas delivery pipeline 7b, induced draft fan 11 and regenerative high temperature oxidation device. The difference from Embodiment 1 is that this embodiment includes multiple regenerative high-temperature oxidation devices (12a, 12b...12x shown in the figure), and the mixed gas delivery pipeline 7b is provided with multiple mixed gas Conveying pipeline 25, described multi-channel mixed gas conveying pipeline 25 communicates with several regenerative high-temperature oxidation devices in parallel, and isolating valves (20a shown in the figure, 20b...20x) and induced draft fans (11a, 11b...11x shown in the figure). All regenerative high temperature oxidizers are control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com