Wet brake drive axle

A technology of wet brakes and drive axles, applied in the direction of brakes, brake components, control devices, etc., can solve the problems of high brake braking capacity, poor assembly and maintainability, complex structure, etc., to improve work stability and control Dynamic stability, easy assembly and on-site maintenance, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

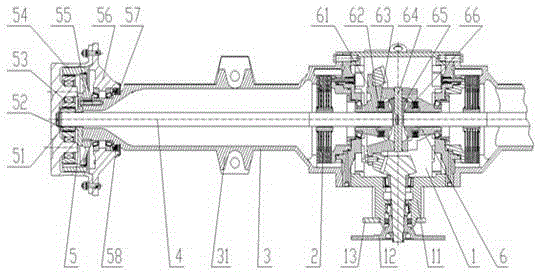

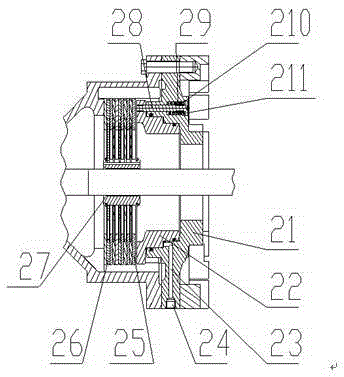

[0021] The invention provides a wet brake drive axle, which includes an axle housing assembly 3, a wet brake 2 placed in the axle housing assembly 3, a main reducer assembly 1 for the central transmission of the whole axle, and a wheel side reducer assembly 5. One end of the half shaft 4 is connected to the main reducer assembly 1, and the other end is connected to the sun gear 52 of the wheel reducer assembly 5. The power is transmitted to the wheel reducer assembly 5 through the main reducer assembly 1, and after being decelerated by the wheel reducer assembly 5, the power is output by the wheel hub 55. It should be noted that the drive axle is a symmetrical structure centered on the main reducer assembly 1, figure 1 1 only shows the structure of one side of the final reducer assembly 1 to clearly show the specific composition and connection relationship.

[0022] The main reducer assembly 1 is supported by the main reducer housing 11, the main reducer housing 11 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com