Paste-like material charging machine

A technology for charging machines and materials, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high production cost, stuck in the equipment, complex structure of sealing equipment, etc., achieve compact structure, reduce failure rate, The action and its adjustment are convenient and flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

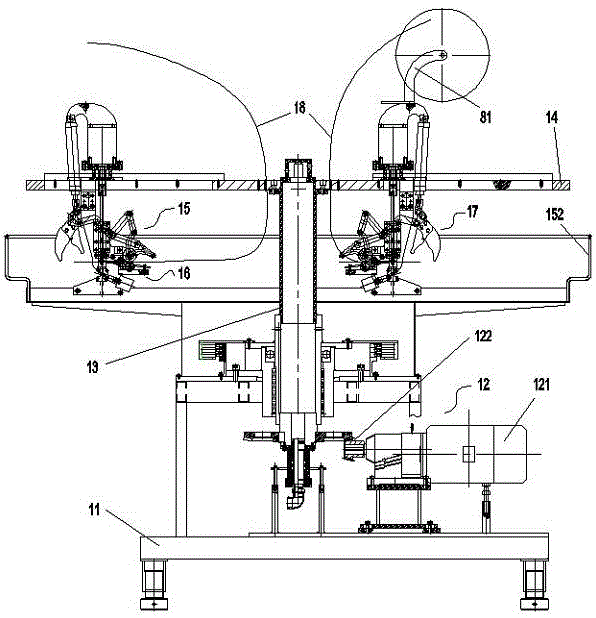

[0032] see figure 1 , the present invention provides a paste material filling machine, which is provided with a turntable wire sealing machine, the sealing machine includes a frame 11, a power system 12, a vertical main shaft 13, a turntable 14 and a punching mechanism 15, the said The turntable is horizontally and fixedly installed on the upper end of the vertical main shaft, the power system is installed on the frame, and the power system drives the vertical main shaft to rotate horizontally.

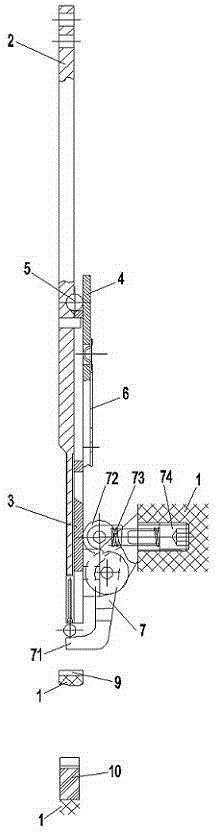

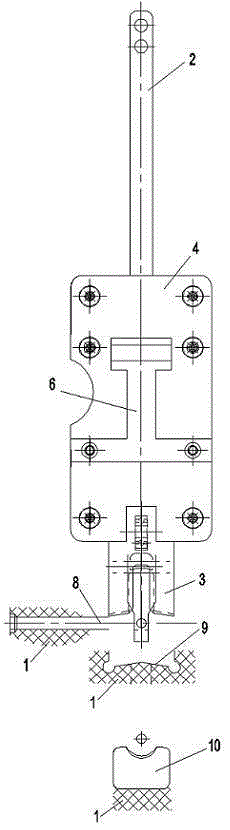

[0033] The punching mechanism is installed on the turntable by means of the machine head vertical plate 1, and the punching mechanism includes a push rod 2, a cut wire piece 3, a cut wire piece baffle plate 4, a steel pin 5, a spring leaf 6 and a hook 7. Driven by the linear drive mechanism, the ejector rod reciprocates linearly up and down. The ejector rod, the cut wire sheet and the cut wire sheet baffle are arranged in a vertical direction, and the left and right are sequentially f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com