Damping and energy absorbing material and preparation method thereof

A technology of energy-absorbing materials and compounds, applied in the field of functional materials, can solve problems such as limited shock absorption performance, human injury, equipment damage, etc., and achieve the effect of simple operation and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

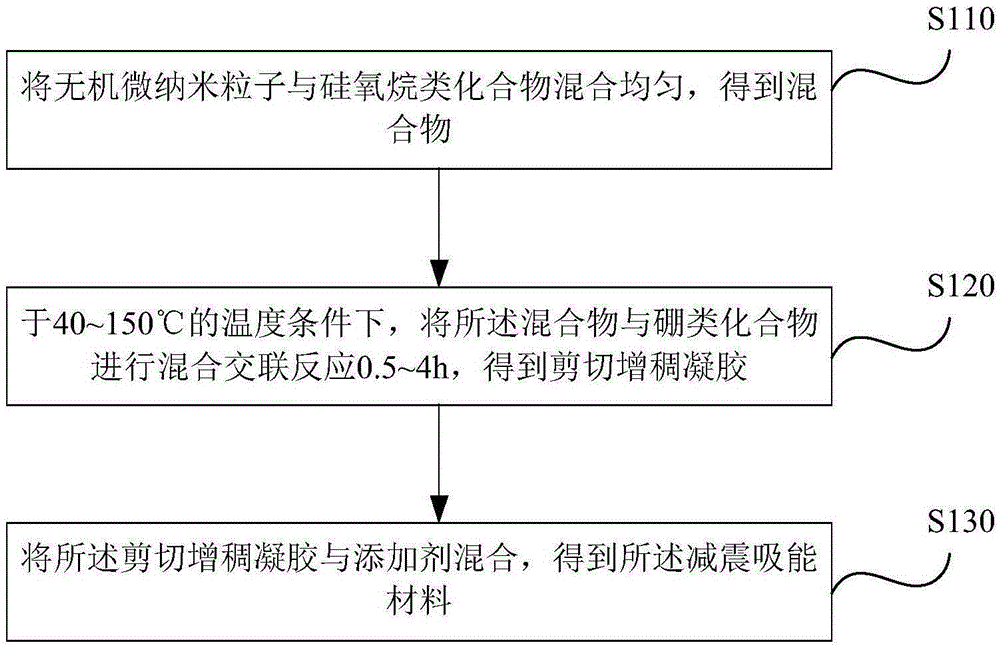

[0021] Such as figure 1 As shown, a method for preparing a shock-absorbing energy-absorbing material in one embodiment includes the following steps:

[0022] Step S110: uniformly mixing the inorganic micro-nano particles and the siloxane compound to obtain a mixture;

[0023] Wherein, the infinite micro-nano particles are SiO 2 、TiO 2 , kaolin, talcum powder, mica powder and montmorillonite at least one, the particle size range of the inorganic micro-nano particles is 50-900nm.

[0024] Among them, the siloxane compounds are dimethyl siloxane, methyl phenyl siloxane, ethyl siloxane, hydroxyl siloxane, phenyl siloxane, hydrogen siloxane, ethyl siloxane, At least one of the oxysiloxanes.

[0025] Preferably, the mass ratio of the inorganic micro-nano particles to the siloxane compound is 0.1%-50%:100%.

[0026] Preferably, the inorganic micro-nano particles are uniformly mixed with the siloxane compound by strong mechanical stirring or ultrasonic waves. The stirring speed ...

Embodiment 1

[0038] The preparation process of the shock-absorbing and energy-absorbing material of this embodiment is as follows:

[0039] First, SiO with a particle size of 300 nm 2 Nanoparticles dispersed into dimethylsiloxane, where SiO 2 The mass ratio of nanoparticles to dimethylsiloxane is 0.1:100, using a strong mechanical stirring at a stirring speed of 500rpm, mixing for 2h, and then mixing the uniformly mixed product with orthoboric acid, mixing and crosslinking at 100°C After reacting for 2 hours, an initial gel with shear thickening properties is obtained, and then the gel is mixed with organic bentonite to improve its performance, and the shock-absorbing and energy-absorbing material is obtained.

Embodiment 2

[0041] The preparation process of the shock-absorbing and energy-absorbing material of this embodiment is as follows:

[0042] First, TiO with a particle size of 50 nm 2 Nanoparticles dispersed into methylphenylsiloxane, where TiO 2 The mass ratio of nanoparticles to methylphenylsiloxane is 50:100, and the stirring speed is 200rpm with strong mechanical stirring, and the stirring time is 2h, and then the uniformly mixed product is mixed with metaboric acid, and mixed at 40°C After 4 hours of combined reaction, a gel with shear thickening performance is obtained initially, and then the gel is mixed with castor oil derivatives to improve its performance, and the shock-absorbing and energy-absorbing material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com