Coupling

A technology for couplings and connecting components, which is applied in the field of displacement compensation couplings, can solve the problems of complex and expensive installation or disassembly, and achieve the effects of small axial length, reduced assembly space, and reduced material stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

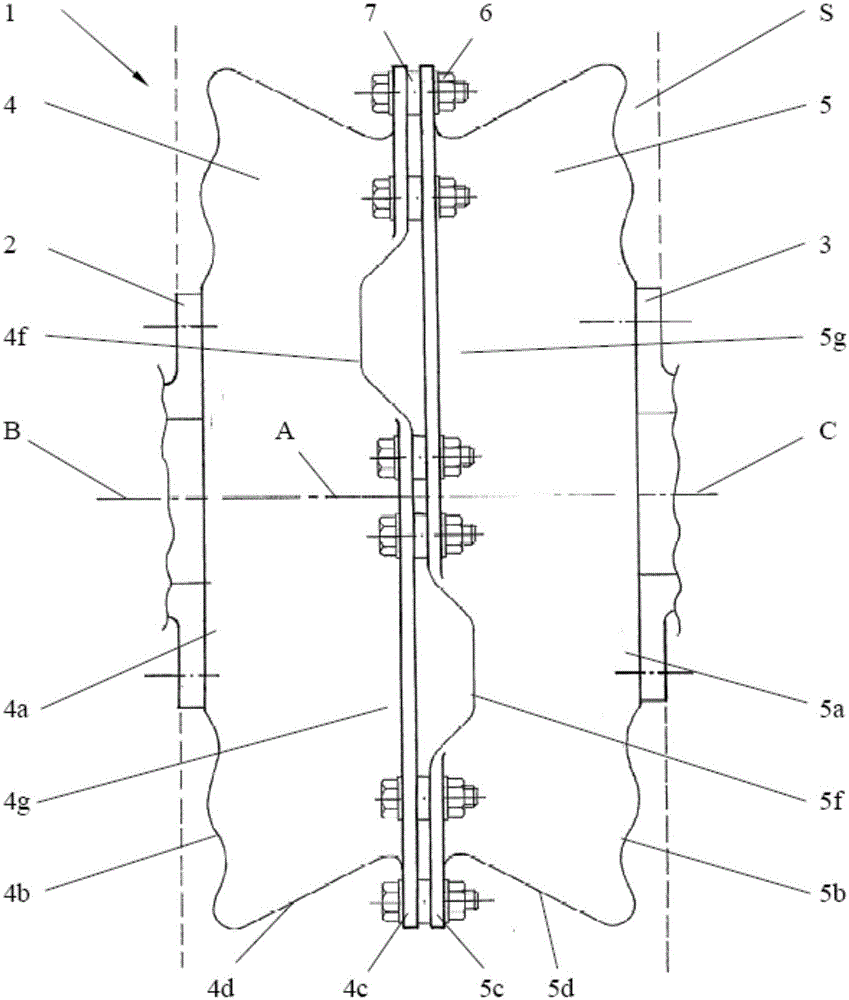

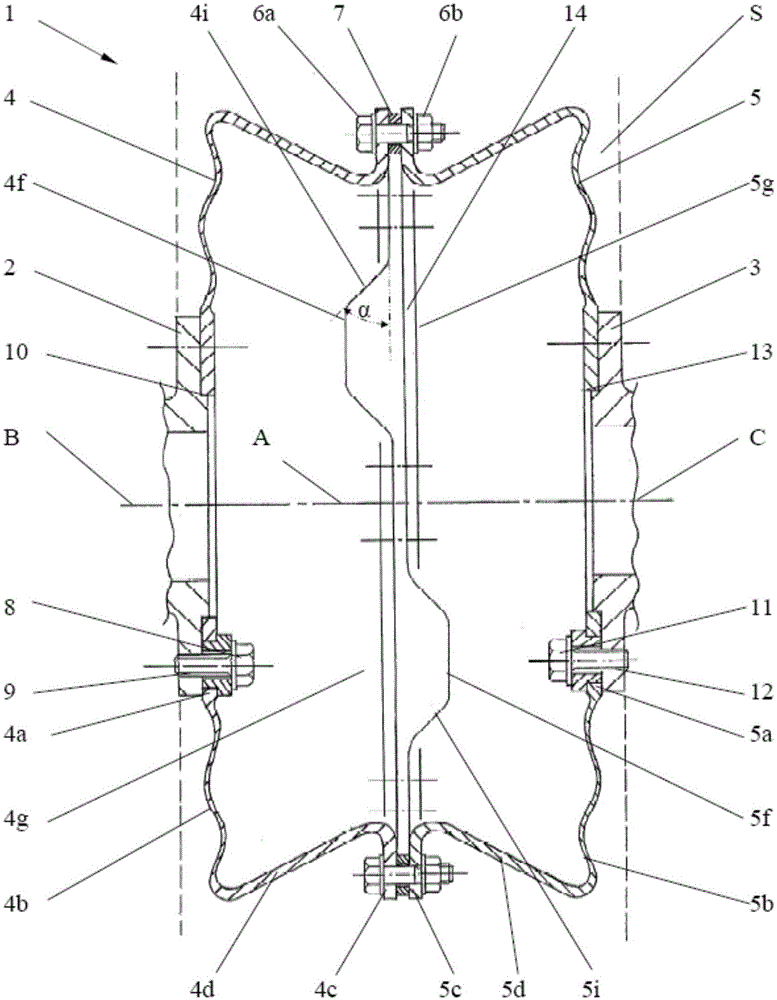

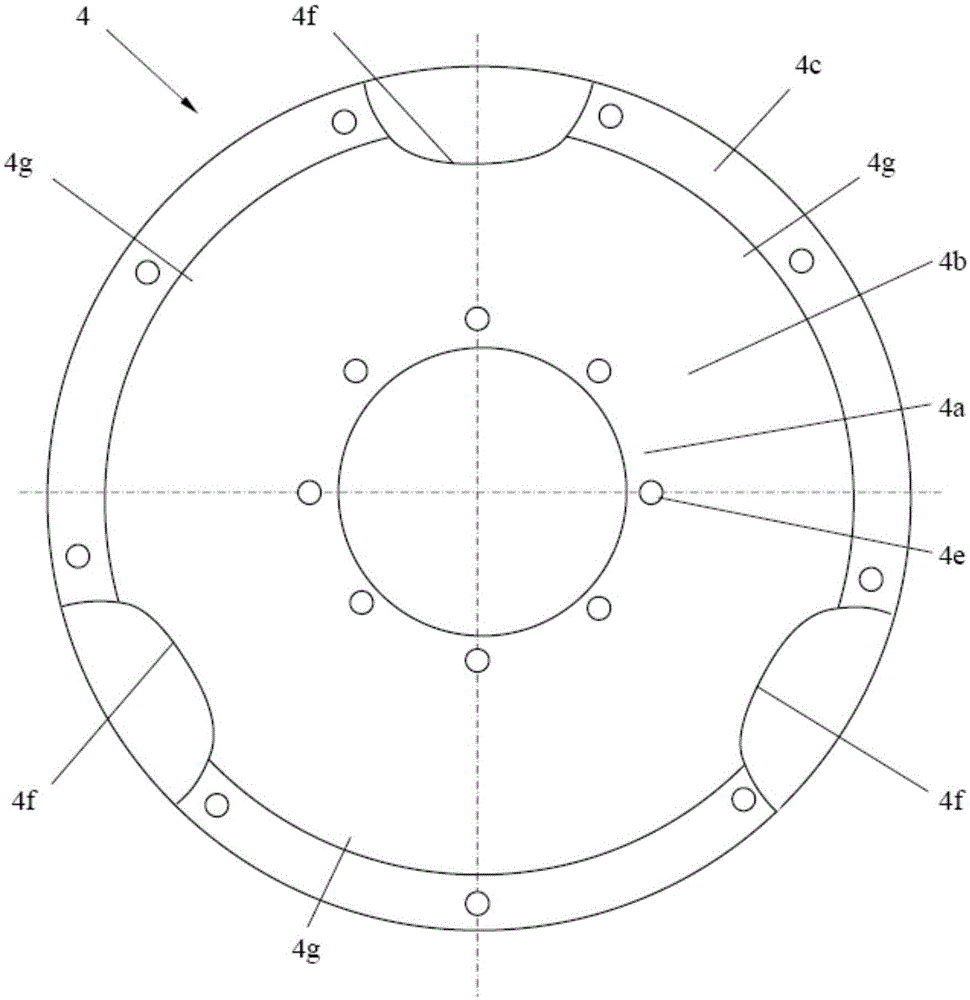

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] What this embodiment shows is the shaft coupling 1 arranged in the transmission system, and the coupling 1 is provided for connecting the first transmission element 2 (driveelement) and the second transmission element 3 (driveelement) of the transmission system, so as to Compensation of angular displacement, axial displacement and radial displacement between transmission elements 2 and 3. The transmission elements 2 and 3 can be arranged in the form of flanges as shown, but can also have other shapes.

[0030] figure 1 The dotted lines shown delimit the extent of the installation space S between the supporting structures of the transmission elements 2 and 3 , which can be, for example, part of the housing of the engine and gearbox of a ship. The coupling 1 can also be provided in a transmission system for other purposes. Essentially, for the purpose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com