Mounting assembly for all-optical overvoltage sensor for overvoltage measurement

A technology for installing components and sensors, which is used in measurement devices, measurement of electrical variables, measurement of current/voltage, etc., can solve the problems of complex operation process and low precision, and achieve the effect of reducing surface electric field, improving dielectric strength, and preventing measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

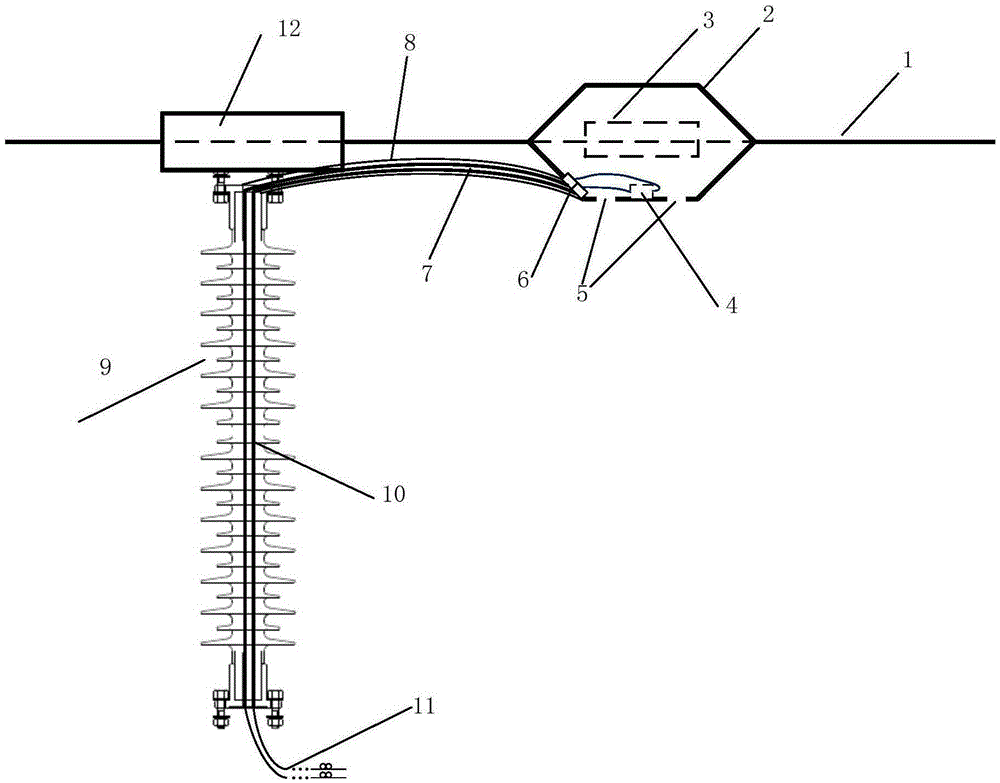

[0017] The installation assembly of a kind of all-optical overvoltage sensor that the present invention proposes, its embodiment structure is as follows figure 1 As shown, it includes: sensor fixed shell 2, power transmission wire expansion sleeve 3, PVC hose 8 and polarization maintaining optical fiber jumper 7 set in the hose, optical fiber insulator 9 with polarization maintaining optical fiber 10 inside and its connection Fittings 12; wherein, the expansion sleeve of the transmission wire is fixed outside the transmission wire, the sensor is installed in the fixed shell of the sensor, and the sensor fixed shell 1 is fixed outside the expansion sleeve of the power transmission wire; the two ends of the PVC hose 8 are respectively connected to the fixed shell of the sensor 2 It is connected with the optical fiber insulator 9, and the two ends of the polarization-maintaining optical fiber jumper 7 in the PVC hose are respectively connected with the pigtail of the sensor and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com