Rotor of a rotating electrical machine

A technology for rotating electrical machines and rotors, applied to electromechanical devices, electrical components, electrical components, etc., can solve the problems of reducing the pressing-fixing force, increasing the number, and high cost, and achieving the effect of avoiding the increase in the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

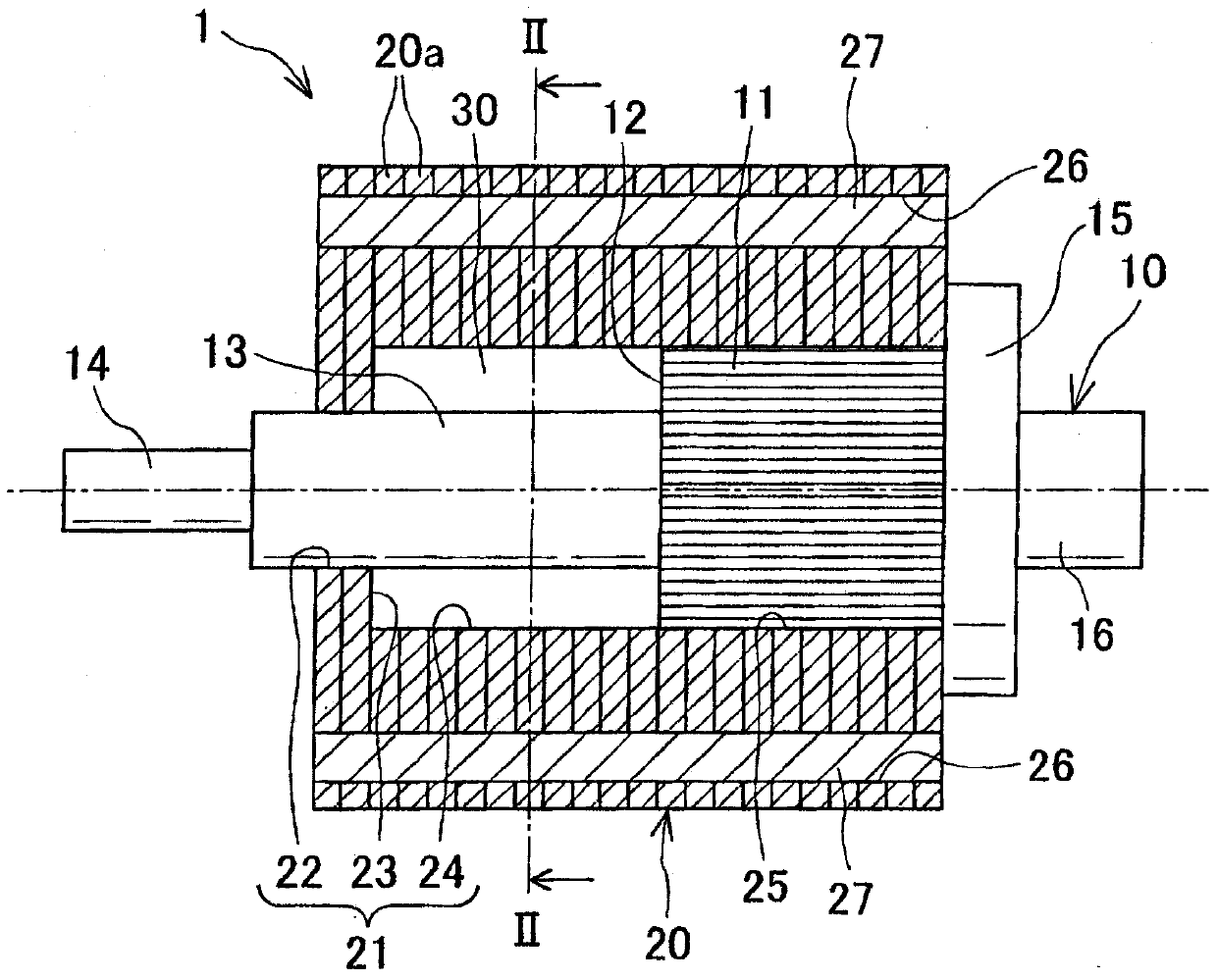

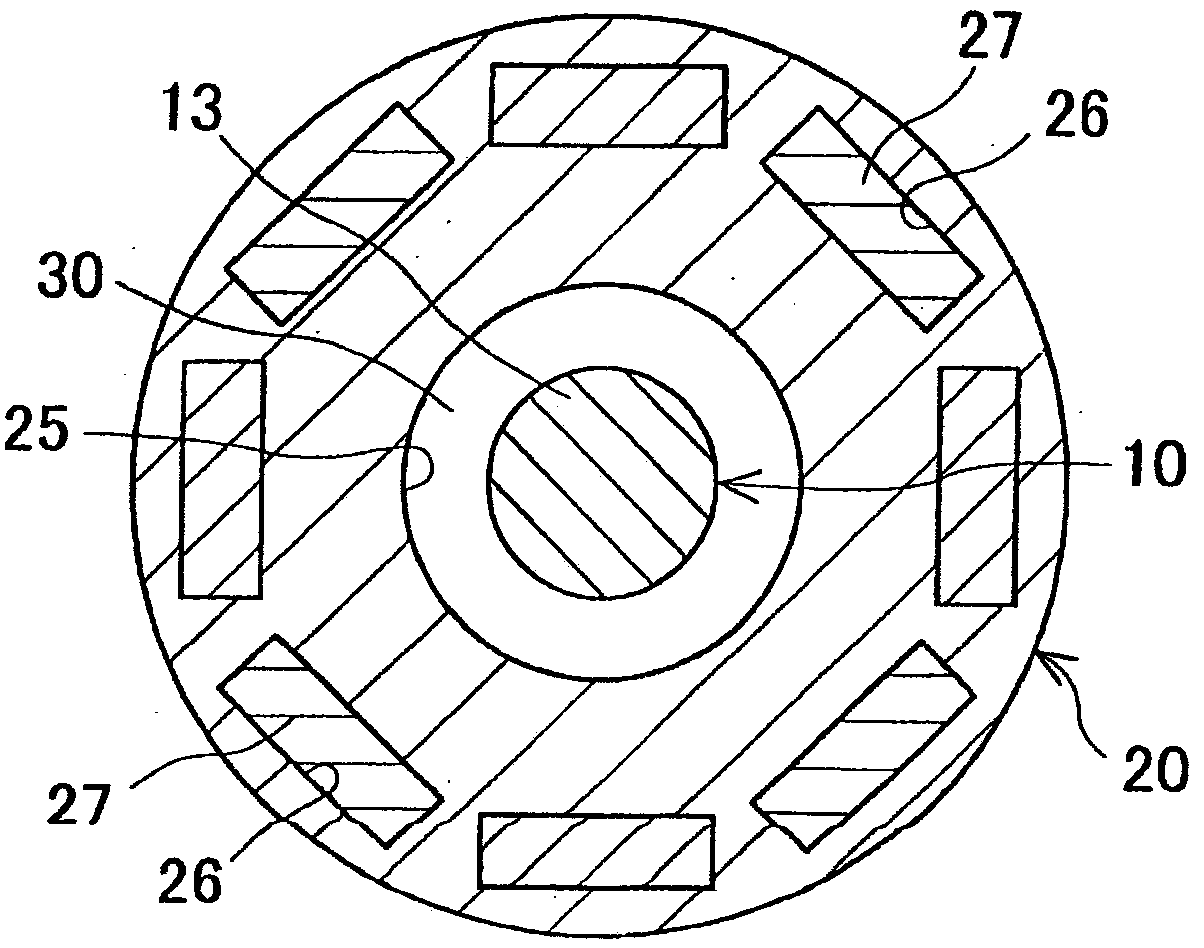

[0029] will refer to figure 1 with 2 The rotor of the rotary electric machine according to the first embodiment is described.

[0030] The rotor 1 of the rotating electrical machine of the first embodiment is used for a rotating electrical machine such as, for example, a motor for a vehicle, and is housed in a casing of the rotating electrical machine while being rotatably provided on the inner periphery of a stator (not shown). on the side.

[0031] Such as figure 1 As shown, the rotor 1 has a shaft 10 having a knurled portion 11 on its outer peripheral surface; and a rotor core 20 having fitting holes coaxially fitted and fixed on the outer peripheral surface of the shaft 10 twenty one.

[0032] The shaft 10 is formed in a solid elongated shaft-like shape made of iron-based metal.

[0033] defined by figure 1 In the axial direction from right to left, the direction in which the shaft 10 is inserted into the fitting hole 21 of the rotor core 20 is taken as the shaft ins...

no. 2 example

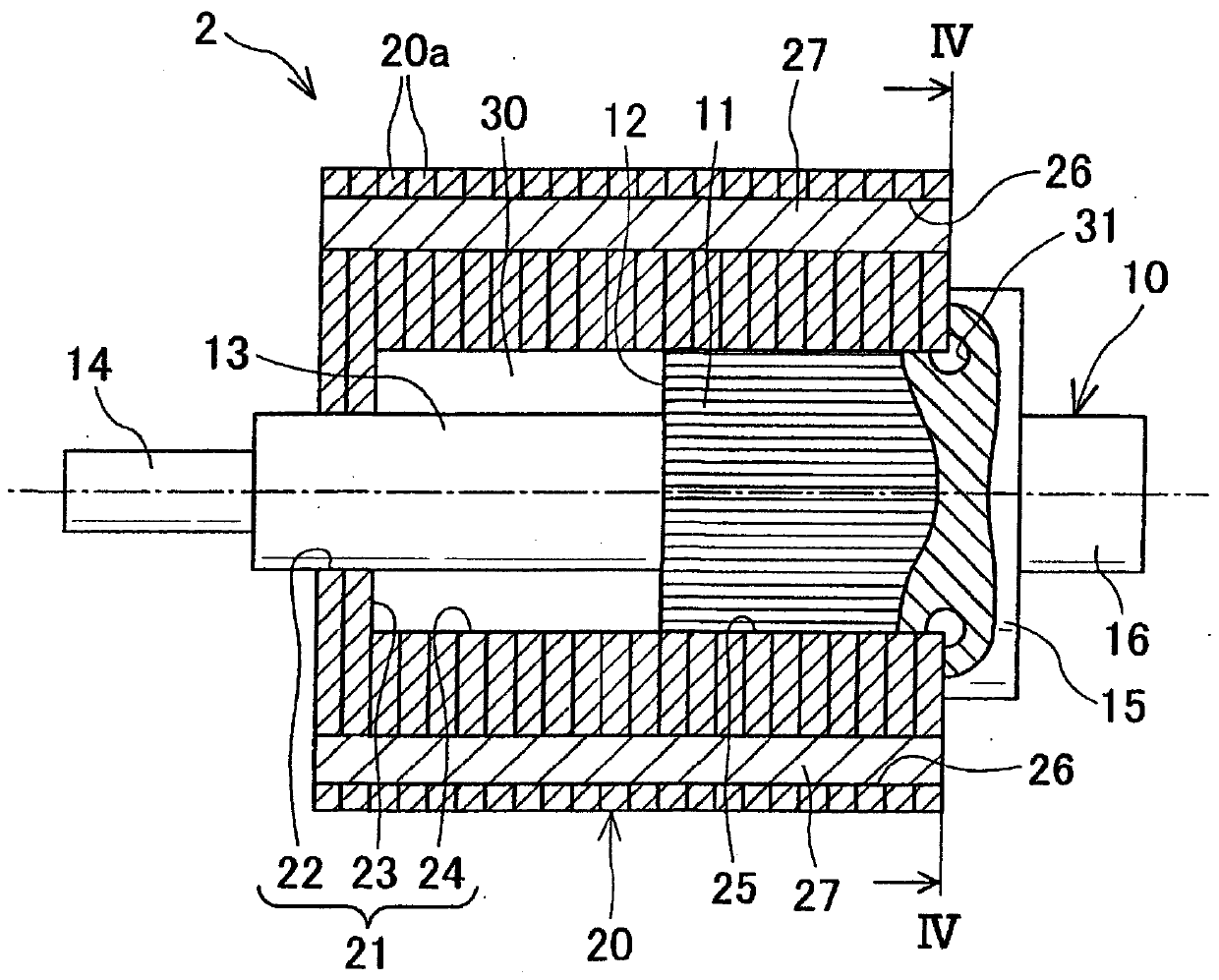

[0075] will refer to image 3 and 4 The rotor 2 of the rotating electric machine according to the second embodiment is described.

[0076] Although the rotor 2 of the second embodiment has the same basic configuration as that of the first embodiment, it differs from the rotor 1 of the first embodiment in that a groove-shaped space portion 31 formed on the shaft 10 is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com