Cooking integrated steamer

An all-in-one, steamer technology, applied in the direction of steam cooking utensils, inserts, cooking utensils lids, etc., can solve the problems of poor quality and taste of the upper food, affecting the appearance and taste of the finished product, soaking and appearance damage, etc., and achieve good sales. The effect of phase and taste, improving efficiency, and shortening cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

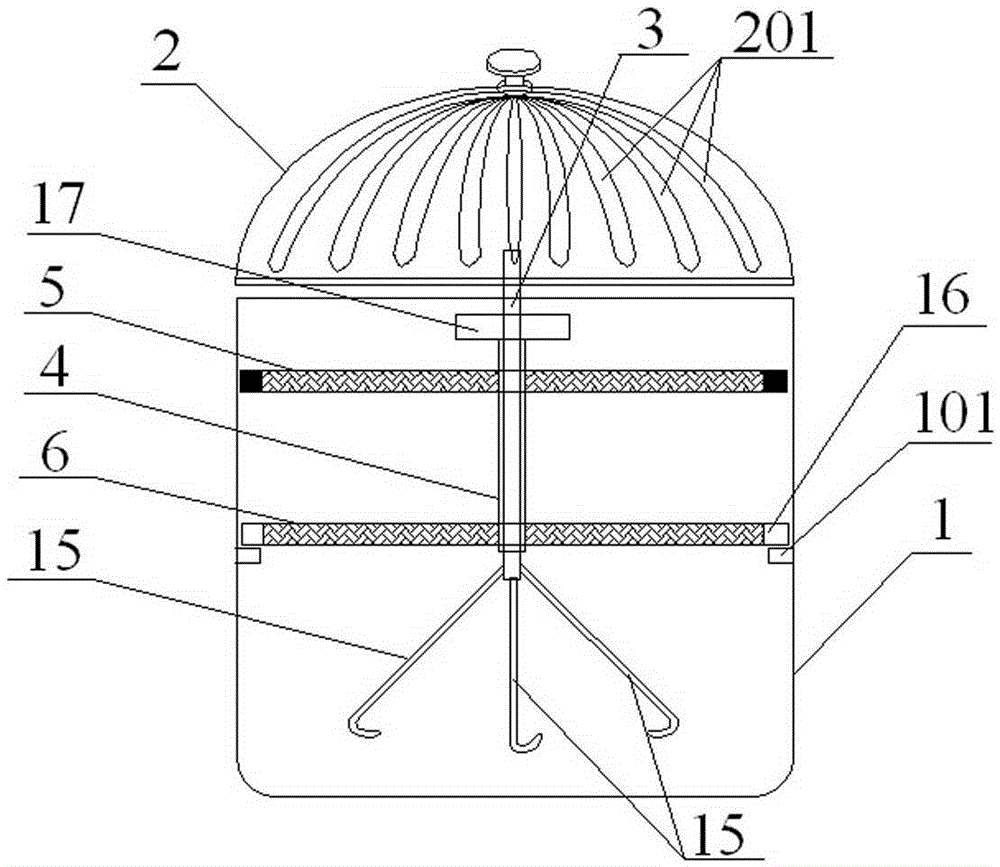

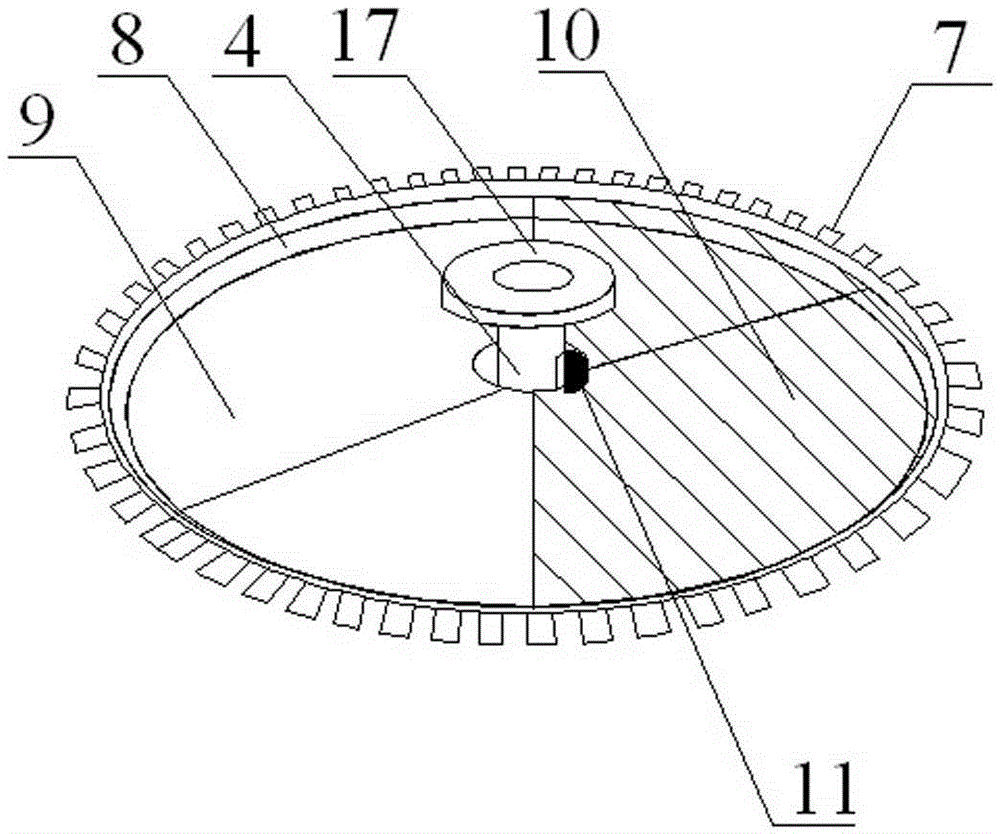

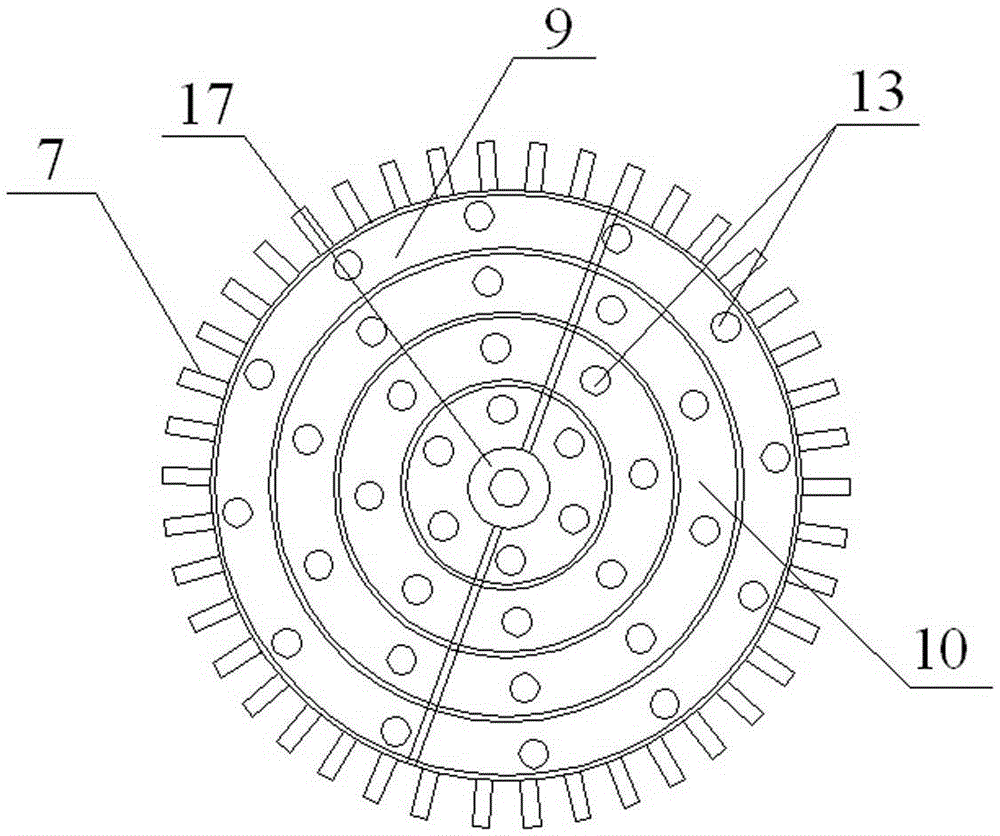

[0031] An integrated steamer for cooking, comprising a pot body 1, a pot cover 2, and a cage grate and a stirring shaft 3 arranged in the pot body 1, the cage grate includes a central axis tube 4 vertically arranged and installed on the The upper cage grate 5 and the lower cage grate 6 on the central axis tube 4, the top of the central axis tube 4 is provided with a ring-shaped handle 17 that is convenient for the cage grate to be taken out from the steamer. The upper cage grate 5 is made of the cage grate body and the ring-shaped retaining ring 7 arranged on the outer circumference of the cage grate body. The outer edge of the ring-shaped retaining ring 7 is fence-shaped, which is convenient for the pot cover The condensed water flowing down from the edge flows into the pot from the gap, and a circular chute 8 is provided on the inner circumference of the annular retaining ring 7, and the cage grate body includes two vertically arranged on the central shaft tube 4 The fan-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com