Essential oil thermocatalysis device

A thermal catalysis, essential oil technology, applied in the direction of gasification substances, atomized substances, chemical instruments and methods, etc., can solve the problems of slow volatilization rate of essential oils, slow volatilization rate, large heat loss, etc., and achieve small heat loss and soft aroma. Natural, temperature-controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

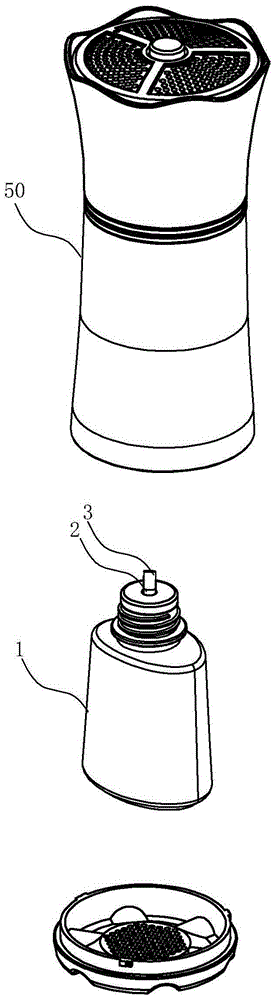

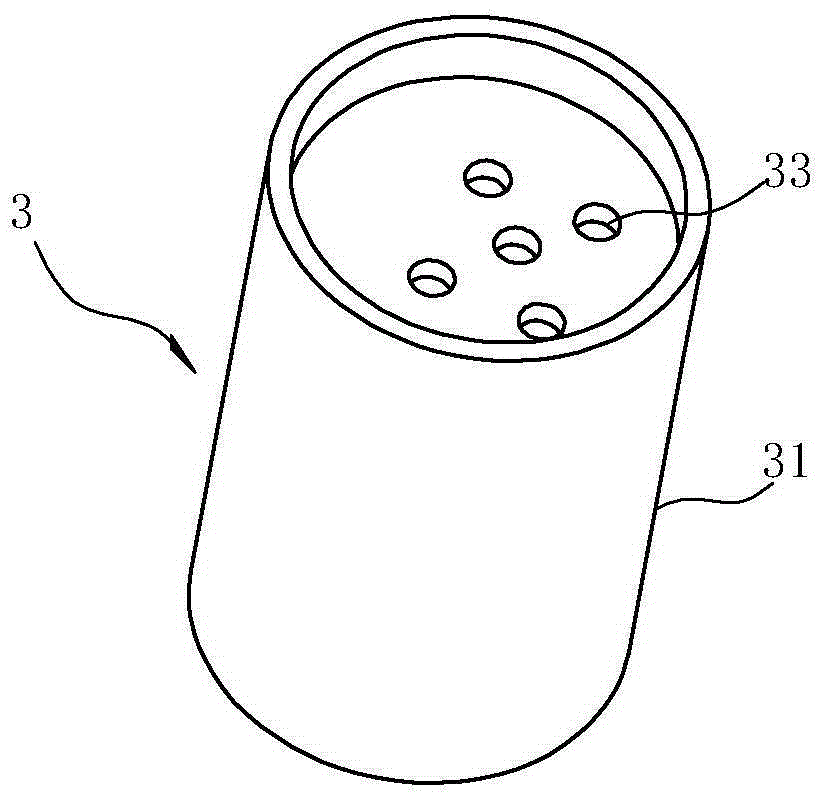

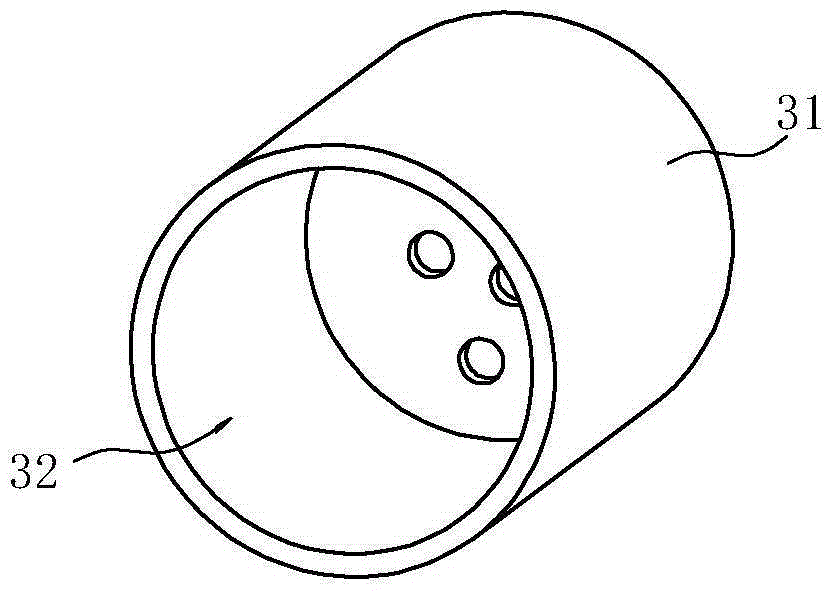

[0026] Such as Figure 1~4As shown, the essential oil thermocatalytic device includes an essential oil bottle 1 for storing essential oil placed in the housing 50 of the air freshener and a catalytic core head 3 installed on the essential oil bottle 1 to convert the essential oil from liquid to gaseous state and distribute it outward , the catalytic core head 3 includes a cover, the cover is surrounded by a convex wall 31 to form a cavity 32 capable of accommodating the mandrel 2 , and the cover is provided with a plurality of through holes 33 relative to the end of the mandrel 2 . In the present embodiment, the catalytic core head 3 is cylindrical to ensure that all the heat of the catalytic core head 3 is used to heat the mandrel 2. The catalytic core head 3 replaces the traditional core head with microporous ceramic material. The core head with microporous ceramic material heats the PTC thermistor by electrifying the electrode, and then continuously lifts the essential oil ...

Embodiment 2

[0030] The difference from Example 1 is that the end of the mandrel 2 is closely attached to the ultrasonic atomizing sheet 4, and the controller on the circuit control board is electrically connected to the atomizing sheet 4 and is used to drive the atomizing sheet 4 to vibrate, and catalyzes when installed. The core head 3 is arranged on the top of the mandrel 2 atomizing sheet 4 with a distance of 1 mm, wherein the catalytic core head 3 can be fixed with a fixing device arranged in the housing 50 of the air freshener, and the specific method is not to be unfolded here. And the end of the mandrel 2 is closely attached to the atomizing sheet 4, and the outlet aperture 41 of the ultrasonic atomizing sheet 4 is 4um. Through the high-frequency resonance of the atomizing sheet, the structure of the essential oil is broken up to produce a natural and elegant water mist , the atomized essential oil is sprayed into the catalytic core head for high-temperature catalysis, and finally e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com