Cutting machine workbench

A technology of workbench and cutting machine, applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of wasting manpower time, loss of top cover, endangering human health, etc., to speed up cutting efficiency, improve efficiency, and protect the environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

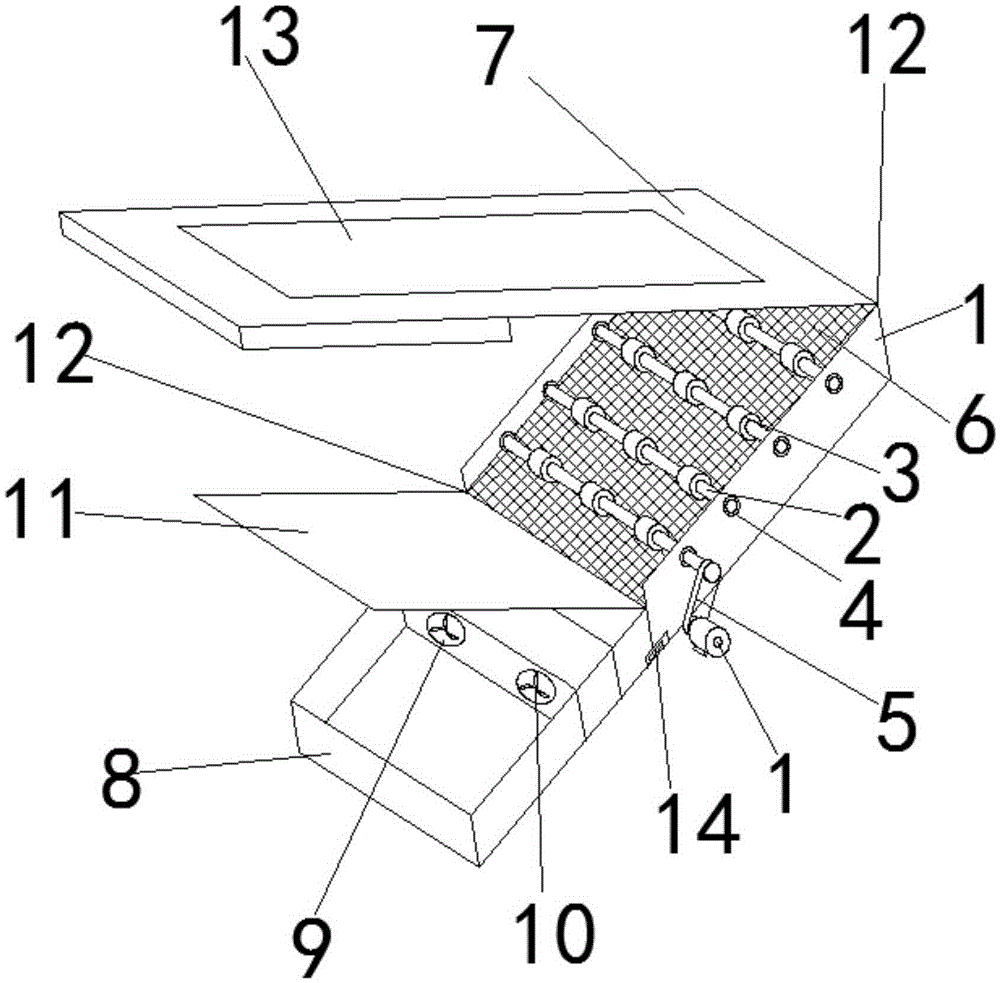

[0017] combined with figure 1 , a workbench of a cutting machine according to the present invention, comprising a workbench 1, the workbench 1 is a square box, the interior is hollow, the top wall and one of the side walls are opened, and several conveyors are arranged at the same height in the workbench 1. frame, the conveying frame includes a rotating shaft 2, and several rotating rollers 3 are evenly arranged on the rotating shaft 2. In this embodiment, three rotating rollers 3 are arranged on the rotating shaft 2, and four conveying frames are arranged at the same height in the workbench 1 , the conveying racks are all connected through the rotating shaft 2 and the bearing 4 fixedly arranged on the side wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com