An Intelligent Clamping Transmission Mechanism

A clamping and conveying, intelligent technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problem of difficulty in ensuring the orderliness and efficiency of materials, inability to detect the position of objects, damage to the mechanical arm or drive system, etc. problems, to reduce the measurement and input process and digital control and positioning links, avoid digital signal errors, enhance speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

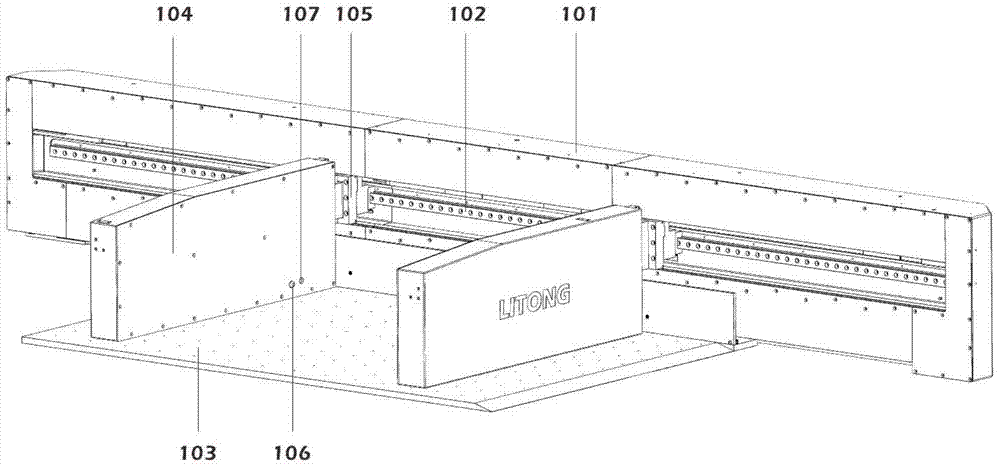

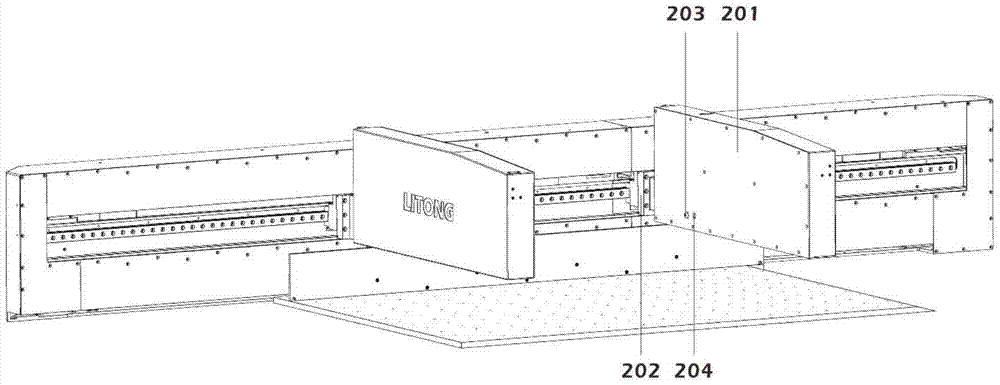

[0018] refer to figure 1 and figure 2 As shown, a kind of intelligent clamping transmission mechanism of the present invention comprises backboard (101), workbench (103), left mechanical arm (104), right mechanical arm (201), mechanical arm track (102), left arm Lifting device (105), right arm lifting device (202), left arm deceleration sensor (107), left arm alignment sensor (106), right arm deceleration sensor (204) and right arm alignment sensor (203). Wherein the workbench (103) is installed on the backboard (101), and the mechanical arm track (102) is fixed on the backboard (101); the left mechanical arm (104) is installed on the mechanical arm track ( 102), the right mechanical arm (201) is installed on the mechanical arm track (102) through the right arm lifting device (202); the left arm deceleration sensor (107) and the left arm alignment sensor (106) are installed on the left mechanical arm ( 104) on the panel, the right arm deceleration sensor (204) and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com