Test stand for video-ranging offshore platform crane heave compensation control system

A technology for heave compensation and offshore platforms, applied in the directions of transportation and packaging, load suspension components, etc., can solve the problems of no large-scale use, inconvenient detection, inappropriateness, etc., and achieve wide practicability, convenient use, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

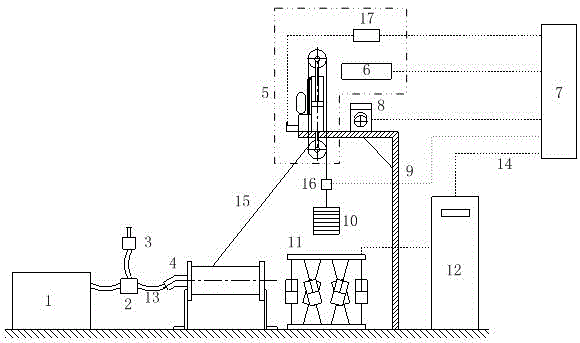

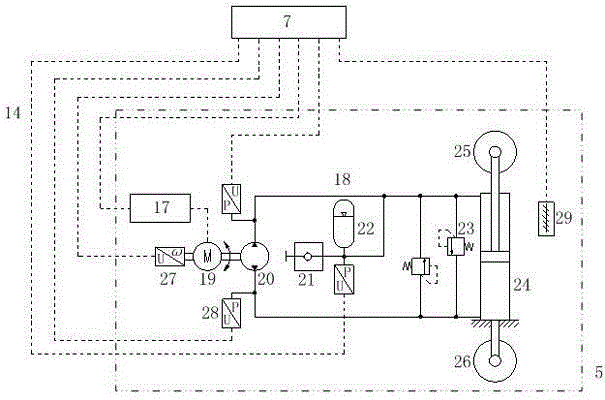

[0020] like figure 1 As shown, the present invention includes a hydraulic oil source 1, a hydraulic control valve 2, a control handle 3, a hydraulic winch 4, a direct pump-controlled electro-hydraulic heave compensation device 5, a control computer 7, an industrial camera 8, a frame 9, and a simulated load 10. Six degrees of freedom platform 11, power distribution control cabinet 12 and tension sensor 16.

[0021] The direct pump-controlled electro-hydraulic heave compensation device 5 and the industrial camera 8 are installed on the frame 9, and one end of the wire rope 15 passes through the static pulley and movable pulley in the direct pump-controlled electro-hydraulic heave compensation device 5, the tension sensor 16 and the analog The load 10 is connected, the other end of the wire rope 15 is connected to the hydraulic winch 4, the hydraulic cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com