Preparation method of chemical surface modification easily-dyed polyimide fabric

A polyimide and surface modification technology, which is applied in the field of chemical surface modification and easy-to-dye polyimide fabric preparation, can solve the problems of polyimide fabrics that are difficult to dye, difficult to dye, and high yarn hairiness. Achieve the effect of improving antibacterial and bactericidal functions and strong bactericidal functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

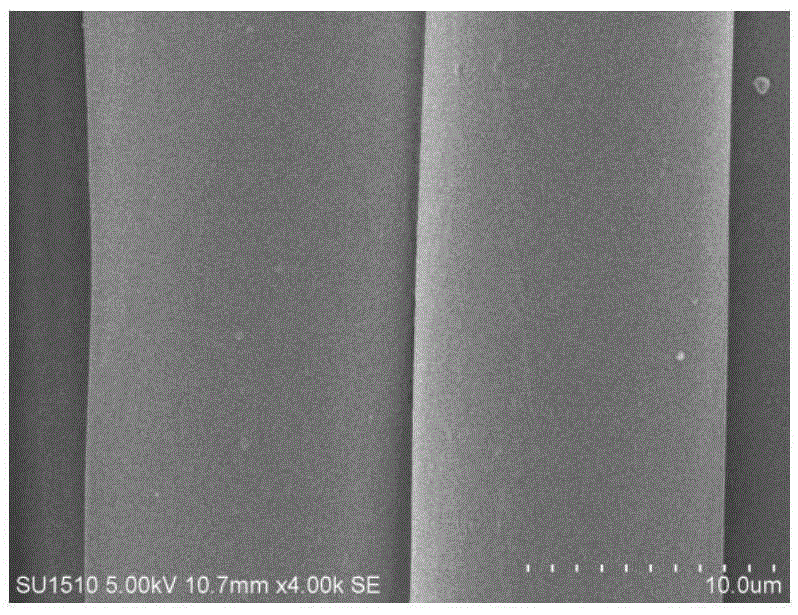

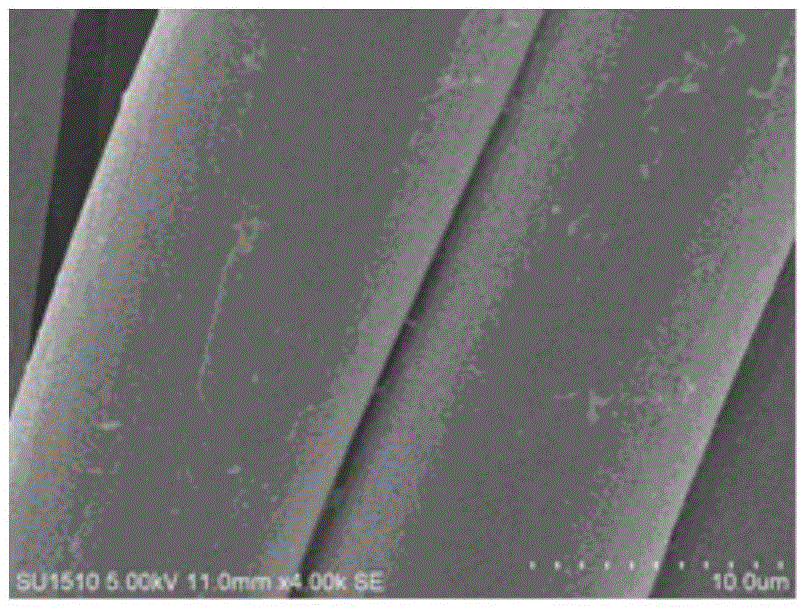

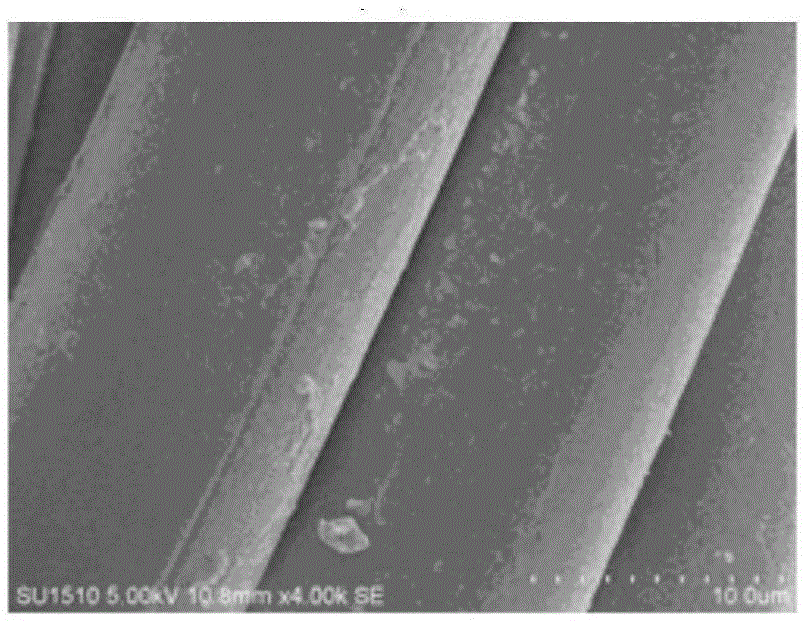

Image

Examples

Embodiment 1-8

[0038] Embodiment 1-8: a kind of preparation method of chemical surface modification easy-to-stain polyimide fabric, comprises the following steps:

[0039] (1) Alkaline solution treatment of polyimide fabrics: The polyimide fabrics are completely immersed in the alkali solution shown in Table 1 respectively and magnetically stirred, the rotating speed is 300-800 rpm, and the temperature is controlled at 25- 50℃, the time is 1-2h;

[0040] (2) Washing of polyimide fabric: take out the polyimide fabric treated with alkali solution, wash it 6-10 times and dry it in an oven at 70-100°C for 1-2 hours .

[0041] Table 1

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com