Box type post processing assembly for diesel vehicle

A diesel vehicle, box-type technology, applied in the direction of exhaust treatment, mechanical equipment, engine components, etc., can solve the problems of poor loading versatility, large space occupation, etc., to achieve convenient reinstallation and use, and good loading versatility , compact structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

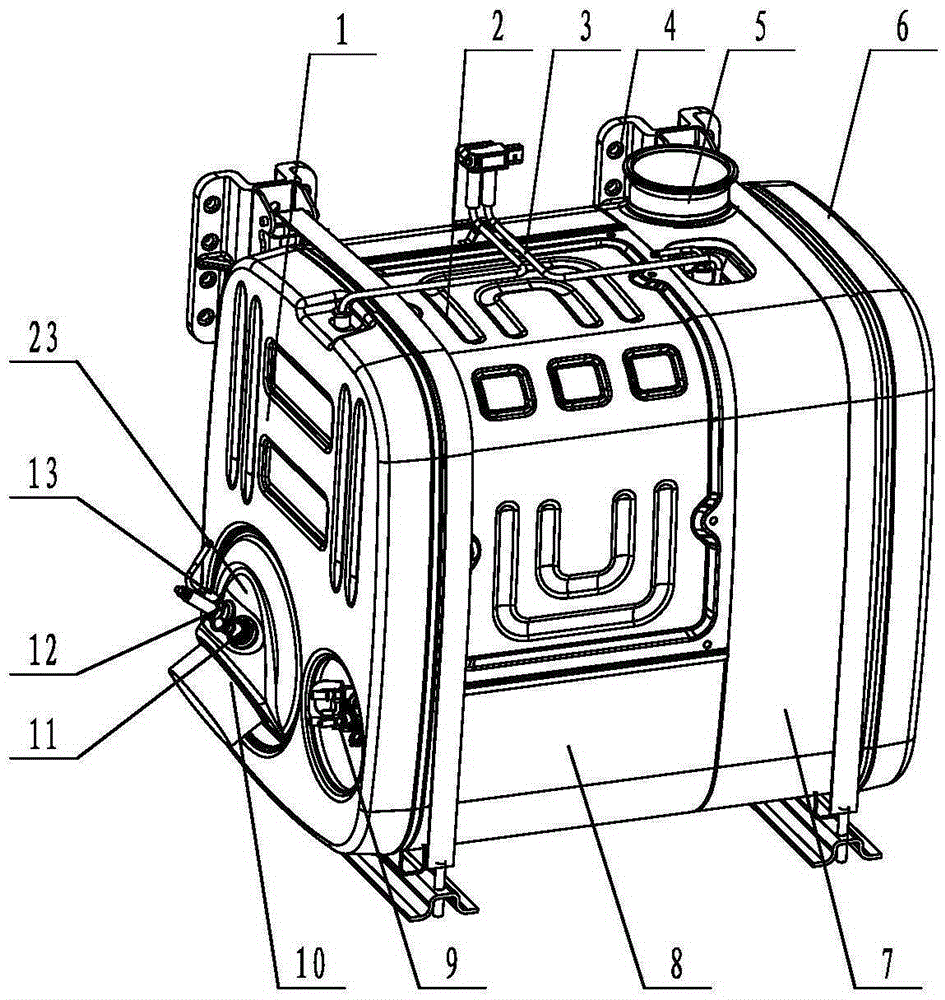

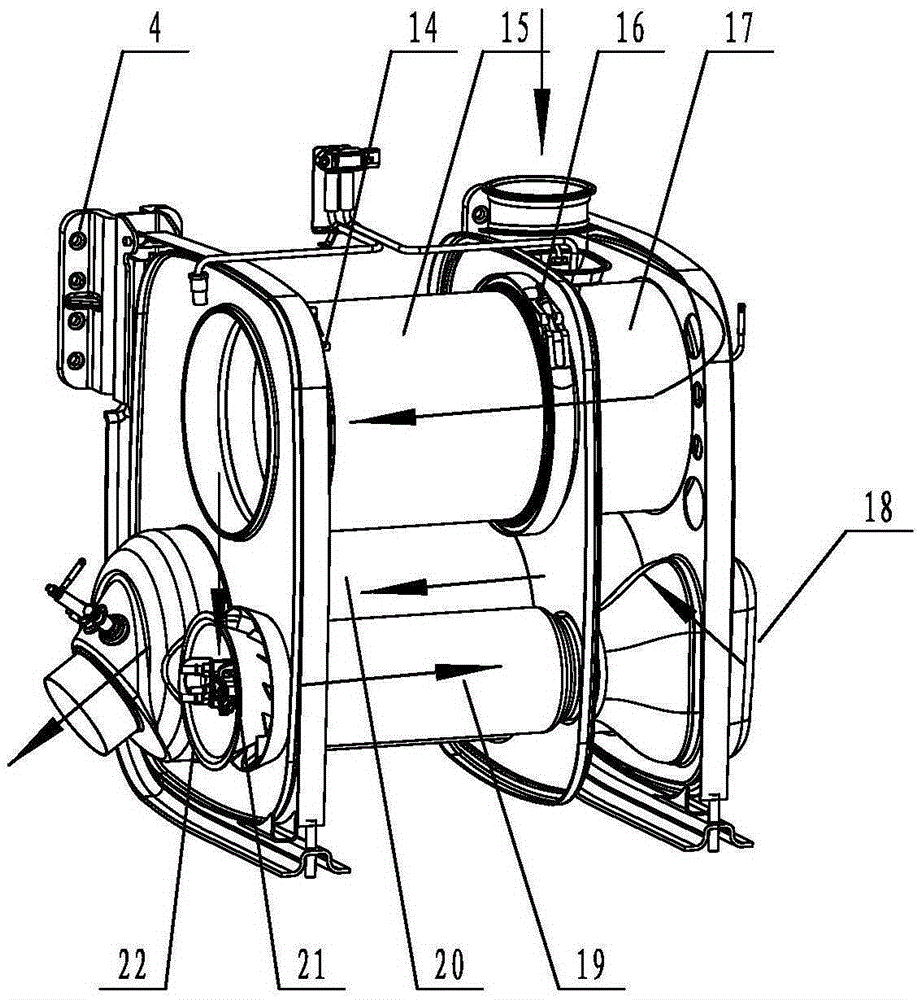

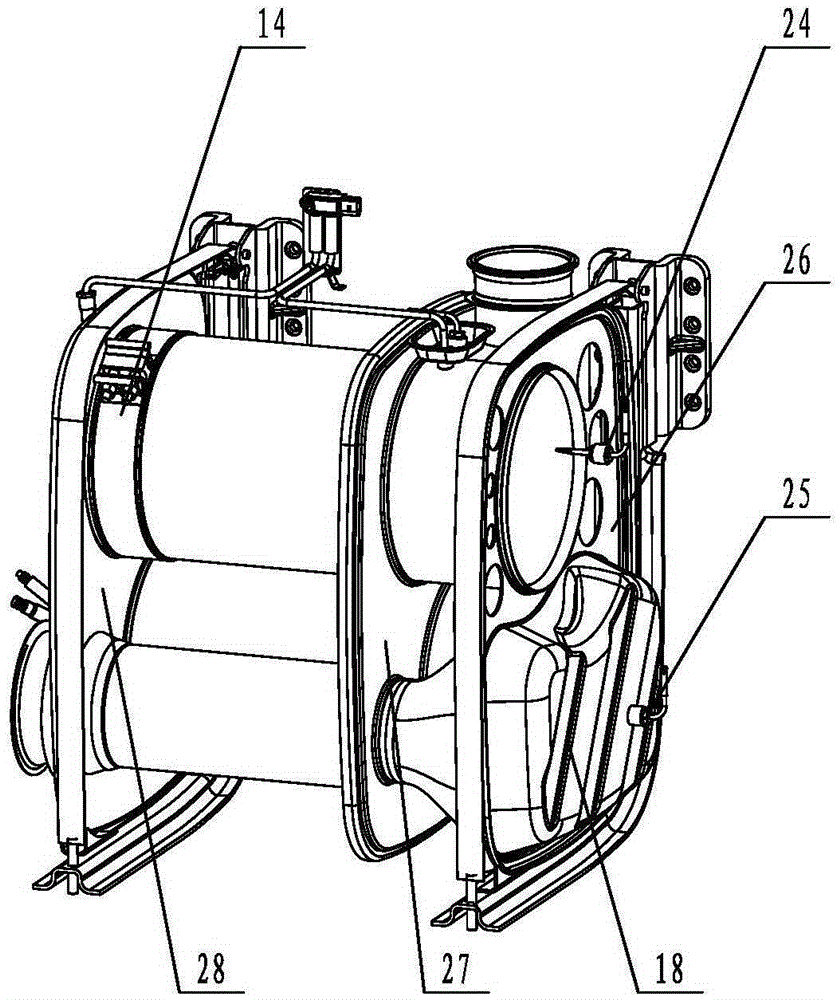

[0017] Figure 1~3 , including rear end cover 1, cover plate 2, differential pressure sensor 3, bracket 4, intake pipe 5, front end cover 6, first box body 7, second box body 8, urea nozzle 9, air outlet 10, nitrogen oxide Matter sensor 11, particle sensor 12, third temperature sensor 13, first hoop 14, particle trap 15, second hoop 16, oxidation catalytic converter 17, first end cover 18, pipeline 19, selectivity Catalytic reduction converter 20, mixer 21, deflector 22, second end cover 23, first temperature sensor 24, second temperature sensor 25, first partition 26, second partition 27, third partition 28 Wait.

[0018] like Figure 1~3 As shown, the present invention is a diesel trunk type aftertreatment assembly, including a particulate trap 15, an oxidation catalytic converter 17, and a selective catalytic reduction converter 20, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com