Nuclear power plant radioactive dry waste processing apparatus

A processing device and radioactive technology, which is applied in the field of processing devices for dry radioactive waste in nuclear power plants, can solve the problems of non-increasing capacity, large volume of solid waste, and complicated interfaces, so as to relieve temporary storage pressure, achieve good economy, and reduce volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

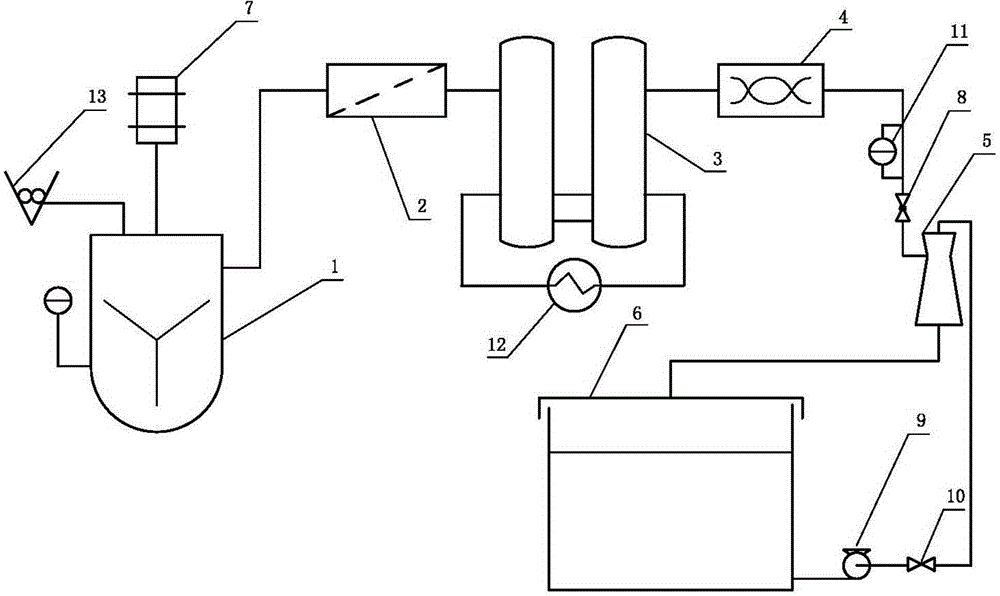

[0017] Depend on figure 1 It can be seen that a treatment device for radioactive dry waste in a nuclear power plant includes a vacuum pyrolysis furnace 1, and the gas outlet of the vacuum pyrolysis furnace 1 is sequentially connected with a pre-filter 2, a U-shaped water tank 3, and a high-efficiency filter through pipelines. 4. The outlet of the high-efficiency filter 4 is connected to the suction port of the water jet 5, one end of the water pump 9 is connected to the water tank, the other end is connected to the water inlet of the hydro jet 5, and the jet port of the hydro jet 5 is connected to the water tank 6; The dry waste is put into the vacuum pyrolysis furnace 1, and the pyrolysis gas produced is filtered through the pre-filter 2 to filter out the particulate matter, and then passed into the U-shaped water tank 3 to filter out the soluble gas, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com