Rotary electromagnet with symmetric magnetic paths

A rotating electromagnet, symmetrical technology, applied in the field of rotating electromagnet, can solve the problems of time-consuming and laborious, and achieve the effect of convenient processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

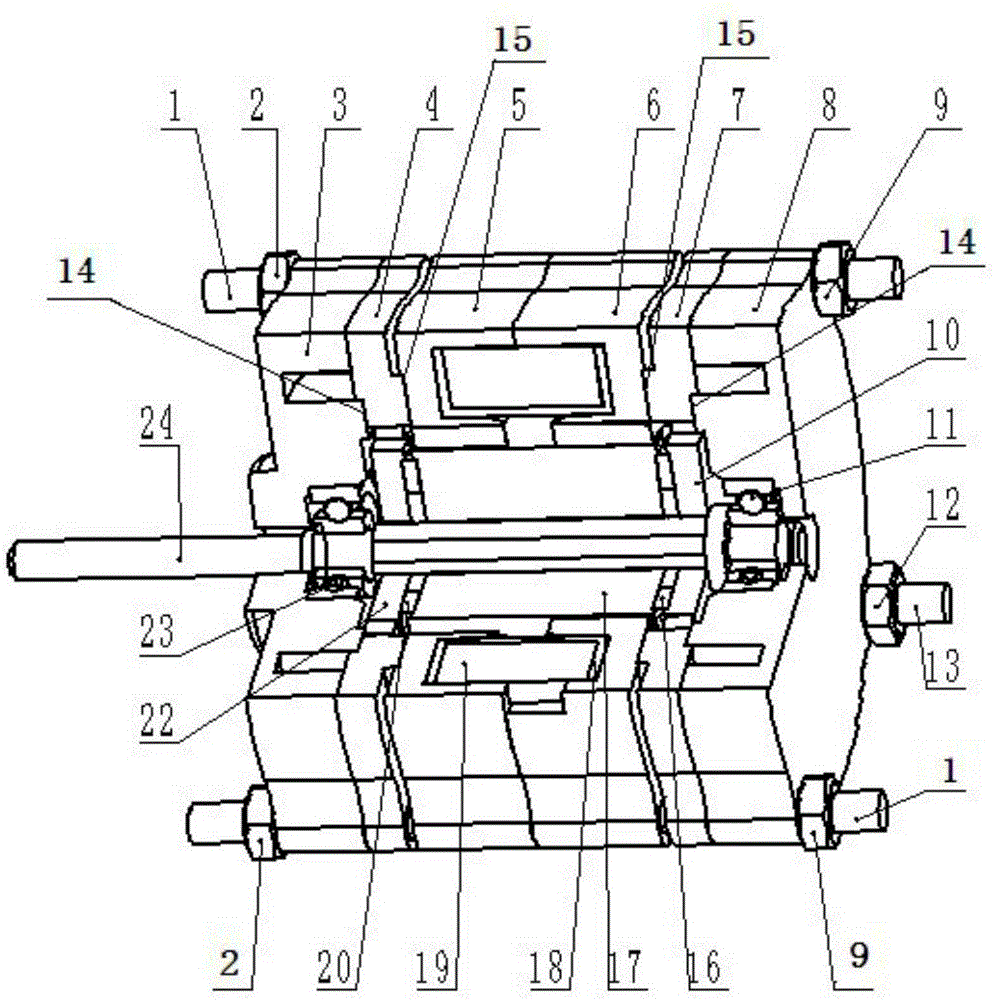

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

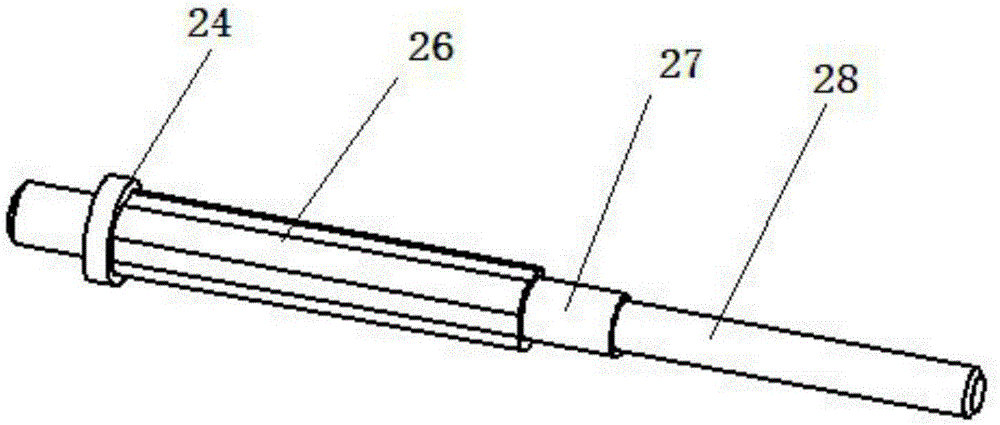

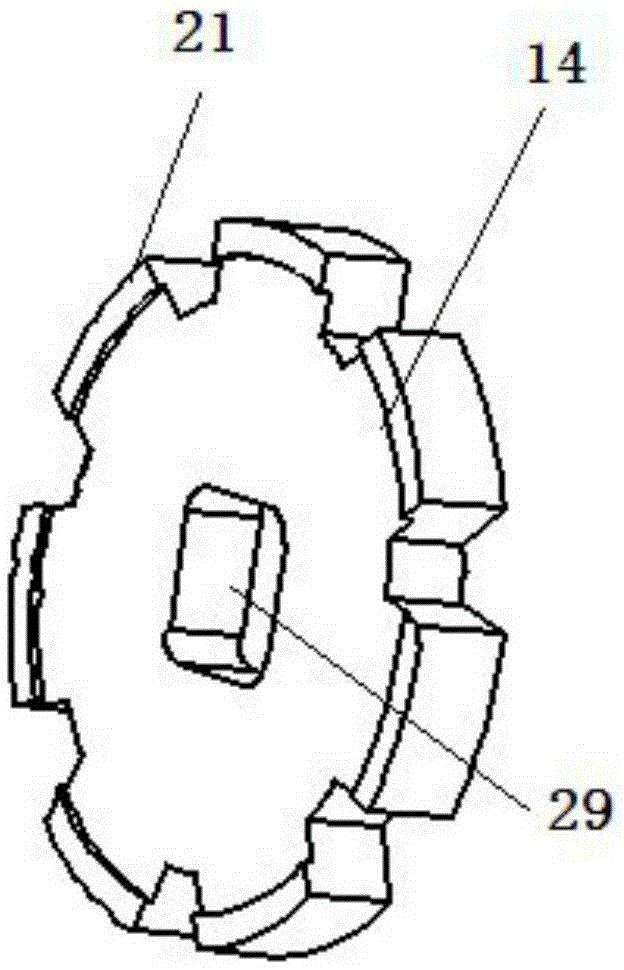

[0025] refer to Figure 1-7 As shown, a rotating electromagnet with a symmetrical magnetic circuit includes a front cover 3 and a rear end cover 8. A rotor component is installed on the front cover 3 and the rear end cover 8, and the front cover on both sides of the rotor component 3 and the rear end cover 8 are respectively equipped with a stator part; the rotor part includes a rotor shaft 24 mounted on the front end cover 3 and the rear end cover 8 through the first bearing 23 and the second bearing 11, which can rotate around the central axis, Both sides of the rotor shaft 24 are respectively equipped with a first permanent magnet 20, a second permanent magnet 16, a first rotor segment 22, a second rotor segment 17 and a third rotor segment 10; Yoke 4 , second yoke 5 , third yoke 6 , fourth yoke 7 , coil 19 , and coil holder 18 .

[0026] The second yoke 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com