A noodle machine convenient for making chewy noodles

A noodle machine and noodle technology, applied in the direction of dough extruder, etc., can solve the problems of lengthening the forming distance of forming holes, thickness limitation, reducing forming efficiency, etc., and achieve the effect of extending the overall depth, facilitating processing and forming, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

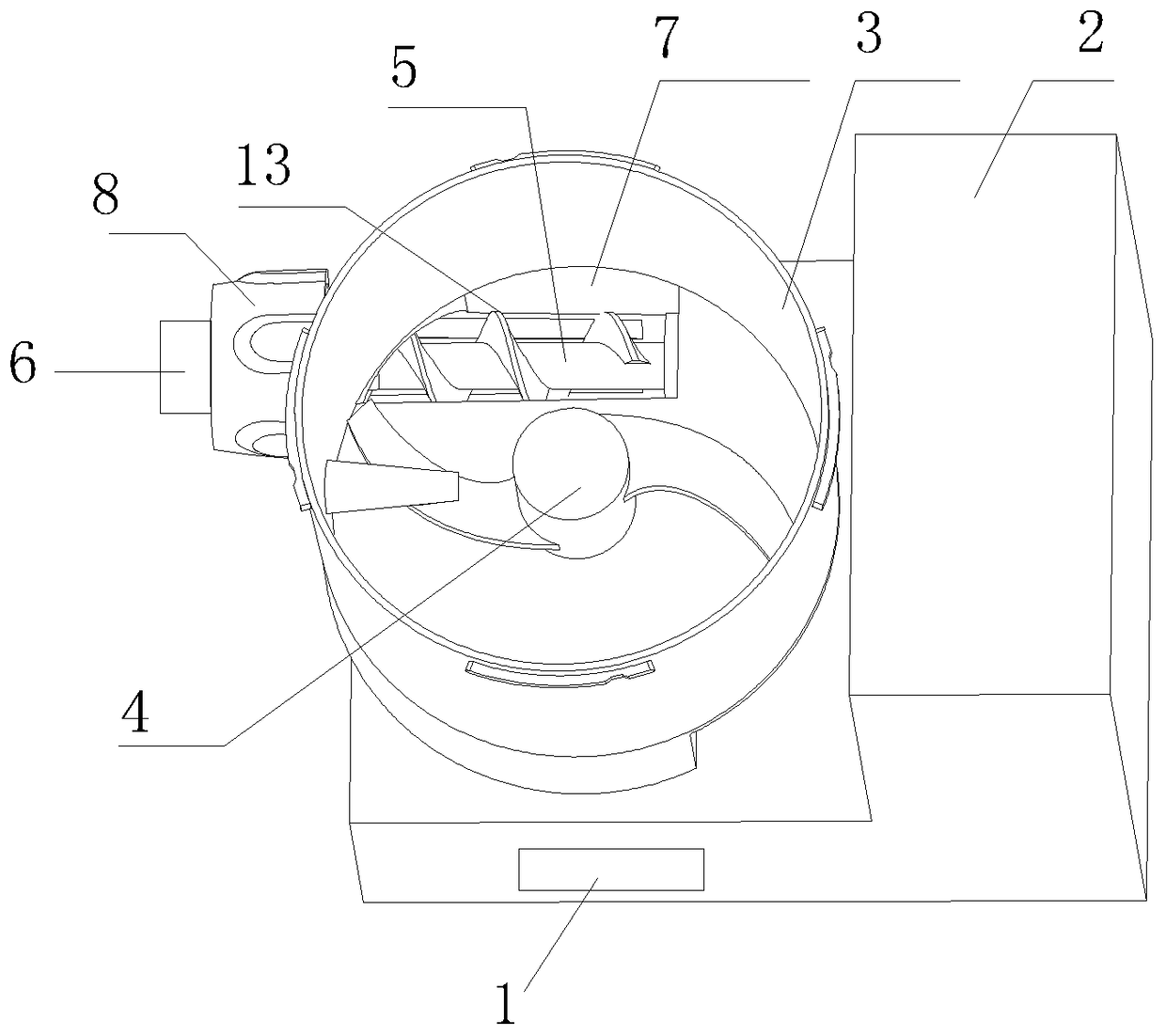

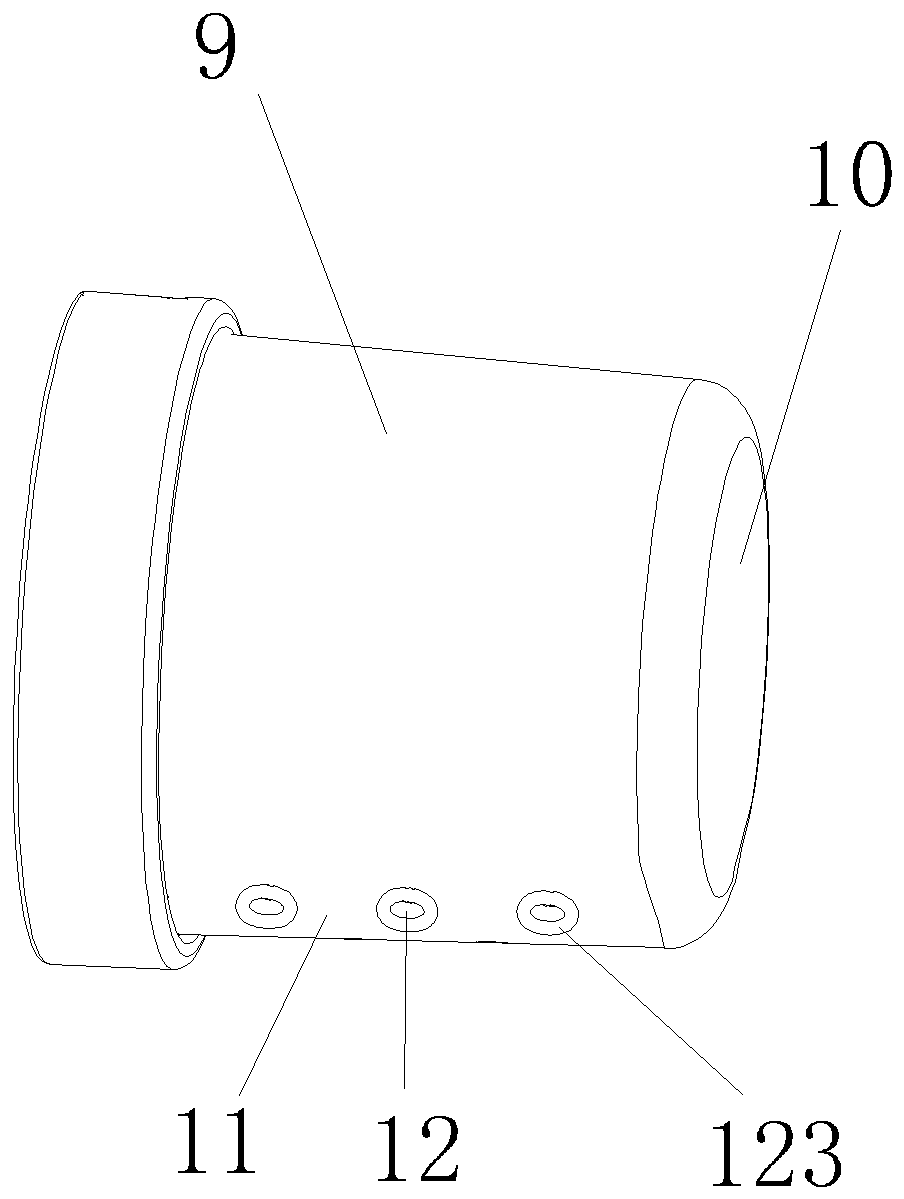

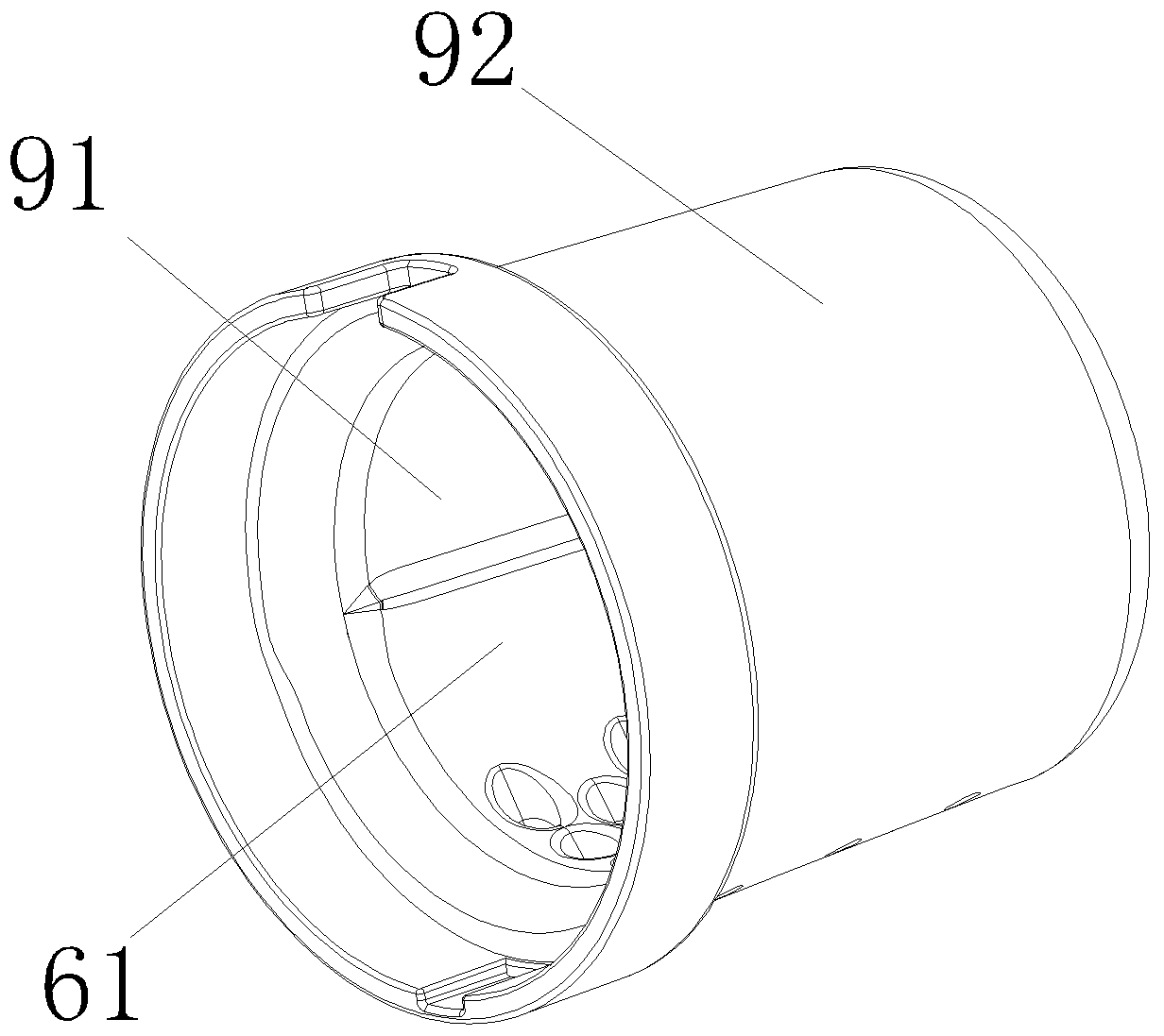

[0035] like figure 1As shown, a noodle machine that is convenient for making hollow noodles is used to knead flour and water into dough and extrude it into noodles. The assembly includes a stirring cup 3 and a stirring rod 4. The extruding assembly includes a screw 5, a die head 6 and a dough extruding barrel 7. The die head 6 is installed at the end of the extruding barrel 7 through a locking member 8. part, the locking piece 8 is screwed to the extruding cylinder 7, the die head 6 includes a side wall 9 that cooperates with the screw 5 and a bottom wall 10 at the end of the side wall 9, and the side wall 9 is provided with a molding Area 11, the forming area 11 is provided with a forming hole 12, the noodle machine described in this embodiment is a vertical noodle machine, that is, the stirring rod 4 is not coaxial with the extruding screw 5, and the bottom of the stirring cup 3 is provided with an inlet The mouth 13, the mixing cup 3 and the extruding cylinder 7 are commun...

Embodiment 2

[0044] like Image 6 As shown, the difference between the present embodiment and the first embodiment is that there are multiple forming holes 12, and the forming holes 12 can be arranged symmetrically, such as arranged vertically or horizontally, or arranged obliquely. The plurality of gathering segments 121 are connected to form a gathering layer 1211, the gathering layer 1211 is arranged along the inner circumferential surface 91, the gathering layer 1211 is concentrically arranged with the inner circumferential surface 91, and the edge of the gathering layer 1211 is in contact with the inner circumferential surface 91. The inner peripheral surface 91 has a smooth transition. Of course, the area of the gathering layer 1211 is smaller than or equal to the area of the forming area 11 , which means that the inner peripheral surface 91 protrudes one layer inward to form the gathering layer 1211 . The advantage of such setting is: by gathering the layer 1211, under the premi...

Embodiment 3

[0048] like Figure 7 As shown, this embodiment is based on Embodiments 1 and 2, and is mainly aimed at the production scheme of the hollow surface. The forming hole 12 is provided with a cylinder 14, the cylinder 14 is cylindrical, and the cylinder The body is located in the extrusion section, and forms an annular extrusion space with the inner wall of the forming hole. The orientation in this embodiment is that the cylinder is located in the extrusion section and the precision molding section, and is flush with the port of the precision molding section, which is convenient Processing, of course, those skilled in the art can also extend the cylinder outward from the port of the precision forming section or extend inward into the port of the precision forming section according to the requirements, as long as the extension distance is within the controllable range of the hollow surface, generally Should not be greater than 1mm.

[0049] Of course, in the case of not setting up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com