Extracting method of folium artemisiae argyi mite-removing cream and folium artemisiae argyi volatile oil

A kind of Artemisia argyi volatile oil and technology of Artemisia argyi, which is applied in the direction of medical formula, medical preparations with non-active ingredients, oil/fat/wax non-effective ingredients, etc., can solve the problems such as the advent of rare traditional Chinese medicine mite removal cream, and achieve dry and non-greasy skin. Aromatic smell and delicate texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

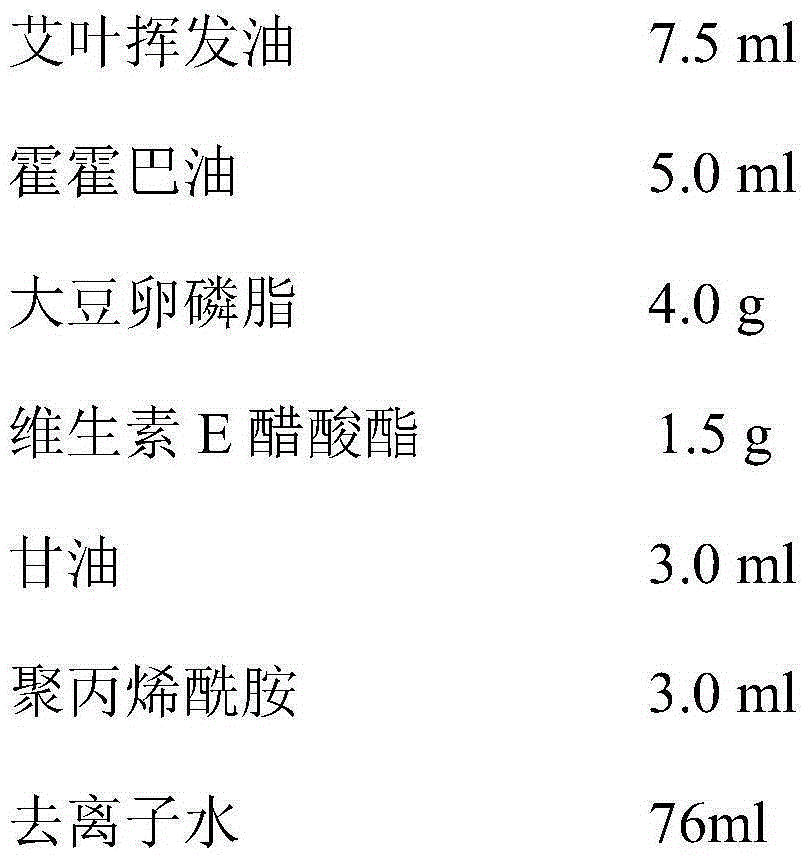

Image

Examples

Embodiment 1

[0029] A method for extracting volatile oil from Folium Artemisiae Argyi, comprising the following steps:

[0030] (1) Take the naturally dried leaves of Artemisia argyi, crush them with a pulverizer (50 mesh), and put them into a supercritical extraction device; turn on the water bath to make the extraction device reach 35°C; 2 , the flow rate is 20Kg / h, replace the air in the system clean; turn on the compressor, adjust the pressure in the extractor to 16MPa; adjust the outlet valve of the extractor to make the CO 2 The flow rate reaches a stable value of 20Kg / h; maintain the system in this state for 80 minutes, the temperature of separation I is 56.0°C, the temperature of separation II is 36°C, the temperature of extraction I is 36°C, open the separator, take out the extract, and weigh it; After the extraction is complete, turn off the compressor and cylinder, and vent the CO 2 , take out the crude product of volatile oil.

[0031] (2) Add the crude product of the extract...

Embodiment 2

[0041] A method for extracting volatile oil from Folium Artemisiae Argyi, comprising the following steps:

[0042] (1) Take the naturally dried leaves of Artemisia argyi, crush them with a pulverizer (50 mesh), and put them into a supercritical extraction device; turn on the water bath to make the extraction device reach 35°C; 2 , the flow rate is 18Kg / h, replace the air in the system clean; turn on the compressor, adjust the pressure inside the extractor to 16MPa; adjust the outlet valve of the extractor to make the CO 2 The flow rate reaches a stable value of 18Kg / h; maintain the system in this state for 80 minutes, the temperature of separation I is 55.0°C, the temperature of separation II is 35°C, and the temperature of extraction I is 35°C. Open the separator, take out the extract, and weigh it; after the extraction is complete, turn off the compressor and cylinder, and vent the CO 2 , take out the crude product of volatile oil.

[0043] (2) Add the crude product of the...

Embodiment 3

[0052] A method for extracting volatile oil from Folium Artemisiae Argyi, comprising the following steps:

[0053] (1) Take the naturally dried leaves of Artemisia argyi, crush them with a pulverizer (50 mesh), and put them into a supercritical extraction device; turn on the water bath to make the extraction device reach 35°C; 2 , the flow rate is 19Kg / h, replace the air in the system clean; turn on the compressor, adjust the pressure inside the extractor to 16MPa; adjust the outlet valve of the extractor to make the CO 2 The flow rate reaches a stable value of 19Kg / h; maintain the system in this state for 80 minutes, the temperature of separation I is 55.5°C, the temperature of separation II is 36°C, and the temperature of extraction I is 35.5°C. Open the separator, take out the extract, and weigh it; after the extraction is complete, turn off the compressor and cylinder, and vent the CO 2 , take out the crude product of volatile oil.

[0054] (2) Add the crude product of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com