Liquid spray foam remover applied to rectifying tower

A rectifying tower and demister technology, applied in the field of liquid mist demister, can solve the problems of inability to remove, high cost, poor mist removal effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

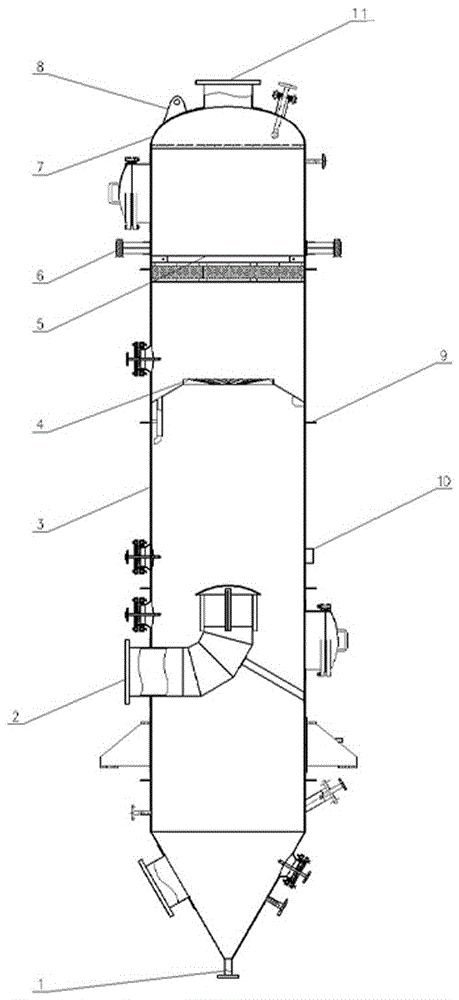

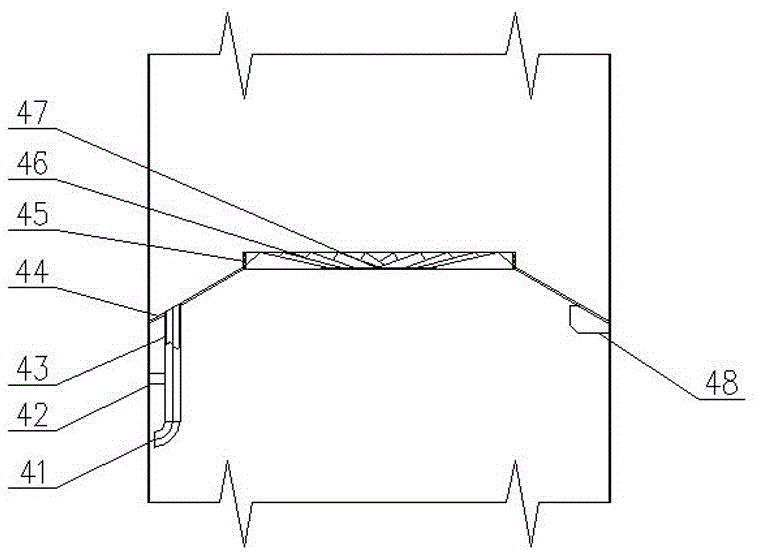

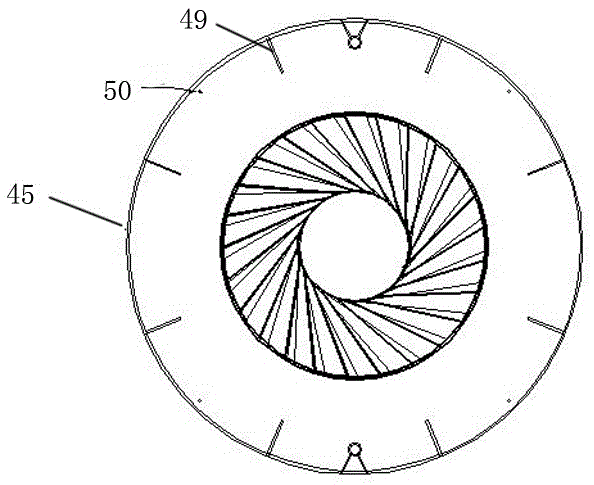

[0020] see Figure 1-4 As shown, the present invention relates to a liquid mist eliminator applied to a rectification tower, comprising a rectification tower shell 3, the top, middle and bottom of the rectification tower shell 3 are respectively provided with a gas outlet 11, a liquid The mist synthesis gas inlet 2 and the liquid outlet 1, the gas outlet 11 are provided with concave and convex surface loose tube flanges 7 and convex surface loose tube flanges 8, and the outer wall of the rectification tower shell 3 is provided with top to bottom respectively There are hanging lugs 6, circulating material inlet and outlet components 9, and sight glass flushing port components 10. The rectification tower shell 3 is provided with a guide ring 5 and a swirl defoaming component 4. The guide ring 5 is provided with Below the gas outlet 11 and above the cyclone demister assembly 4, the cyclone demister assembly 4 is located above the liquid mist synthesis gas inlet 2, and the cyclone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com