A kind of coating granulation material machine

A technology of coating granulation and material machine, applied in chemical/physical processes, methods of granulating raw materials, chemical instruments and methods, etc., can solve the problems of inconvenient replacement of filter elements, poor recovery effect, waste of materials, etc. Achieve the effect of simple structure, high regularity and good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

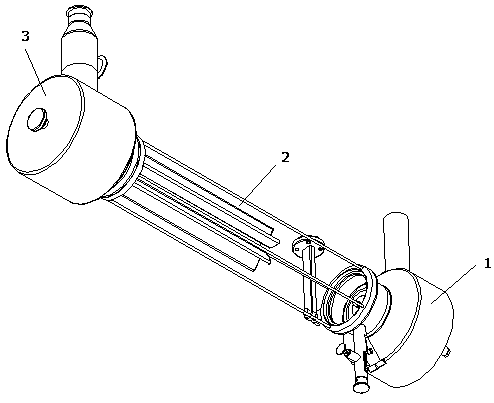

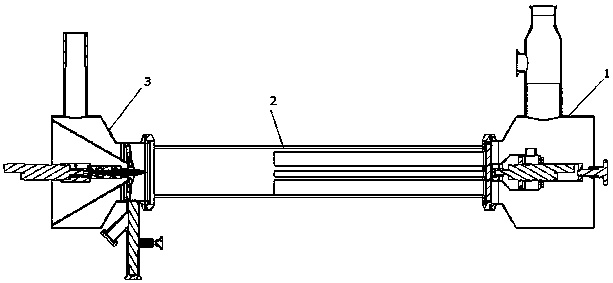

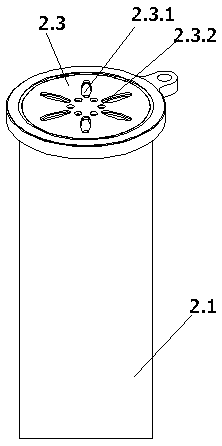

[0014] Embodiment 1: A kind of recovery device of coating granulation material machine, comprises the granulation device 1 of bottom end, the recovery device 2 that lower end is connected with the upper end of granulation device 1, the drying and purging device 3 that is connected with recovery device 2 upper end, The recovery device 2 includes a glass tube body 2.1, which is provided with a filter element 2.2 inside the glass tube body 2.1, and a middle section flange 2.3 is set on the top of the glass tube body 2.1, and the middle section flange 2.3 is provided with 6 radial elliptical holes around the center of the circle 2.3.1, the filter element 2.2 is an oval hollow strip, the upper end of the filter element 2.2 is inserted into the oval hole 2.3.1, and the center of the middle flange 2.3 is provided with five tapered holes 2.3.2. The granulation device 1 includes a spray tower 1.1 with openings at both ends. The spray tower 1.1 includes a large-diameter section 1.1.1 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com