Prediction method of bending angle of titanium alloy laser bending forming part

A technology of bending forming and predicting methods, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve problems such as poor bending angle accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific steps of the method for predicting the bending angle of titanium alloy laser bending forming parts of the present invention are as follows:

[0039] Take the prediction of bending angle of TC4 alloy laser bending forming parts as an example.

[0040] (1) Carry out wire cutting of the TC4 alloy plate in the supply state to obtain strip samples with a thickness of 0.8, 1, 1.5, 2.0mm, a width of 20, 30, 40, 50, 40mm, and a length of 50mm;

[0041] (2) Clean the TC4 alloy sample with absolute ethanol, and apply Ti-β coating on its cleaning surface;

[0042] (3) Fix the TC4 alloy plate on the fixture, perform laser scanning bending on the surface of the plate, air cool to room temperature after laser bending, and measure the maximum bending angle on the center line of the sample length direction after laser bending;

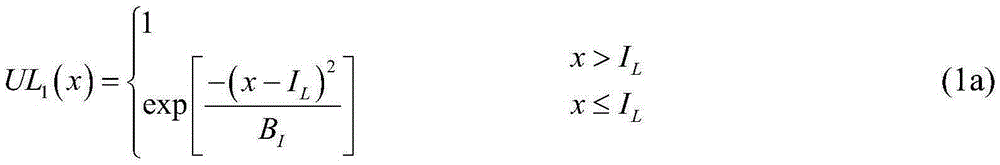

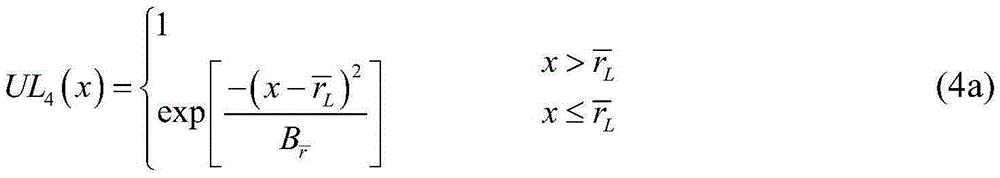

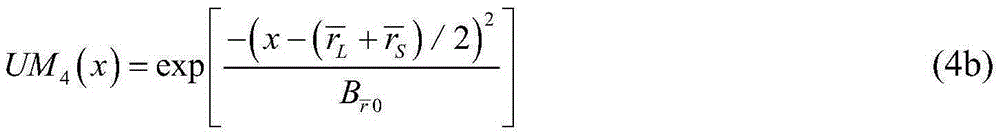

[0043] (3) The energy density (I, J / mm 2 ), sheet width (b, mm), sheet thickness (t, mm), scanning path curvature ( mm -1 ) for normalization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com