A carbon fiber plate surface processing method and injection molding device used for the method

A processing method and surface processing technology, applied in the direction of coating, etc., can solve the problems affecting normal communication, the signal of electronic products cannot be received and output normally, and the effect of texture cannot be displayed, so as to achieve lightweight shielding risk and avoid shielding Risk, the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

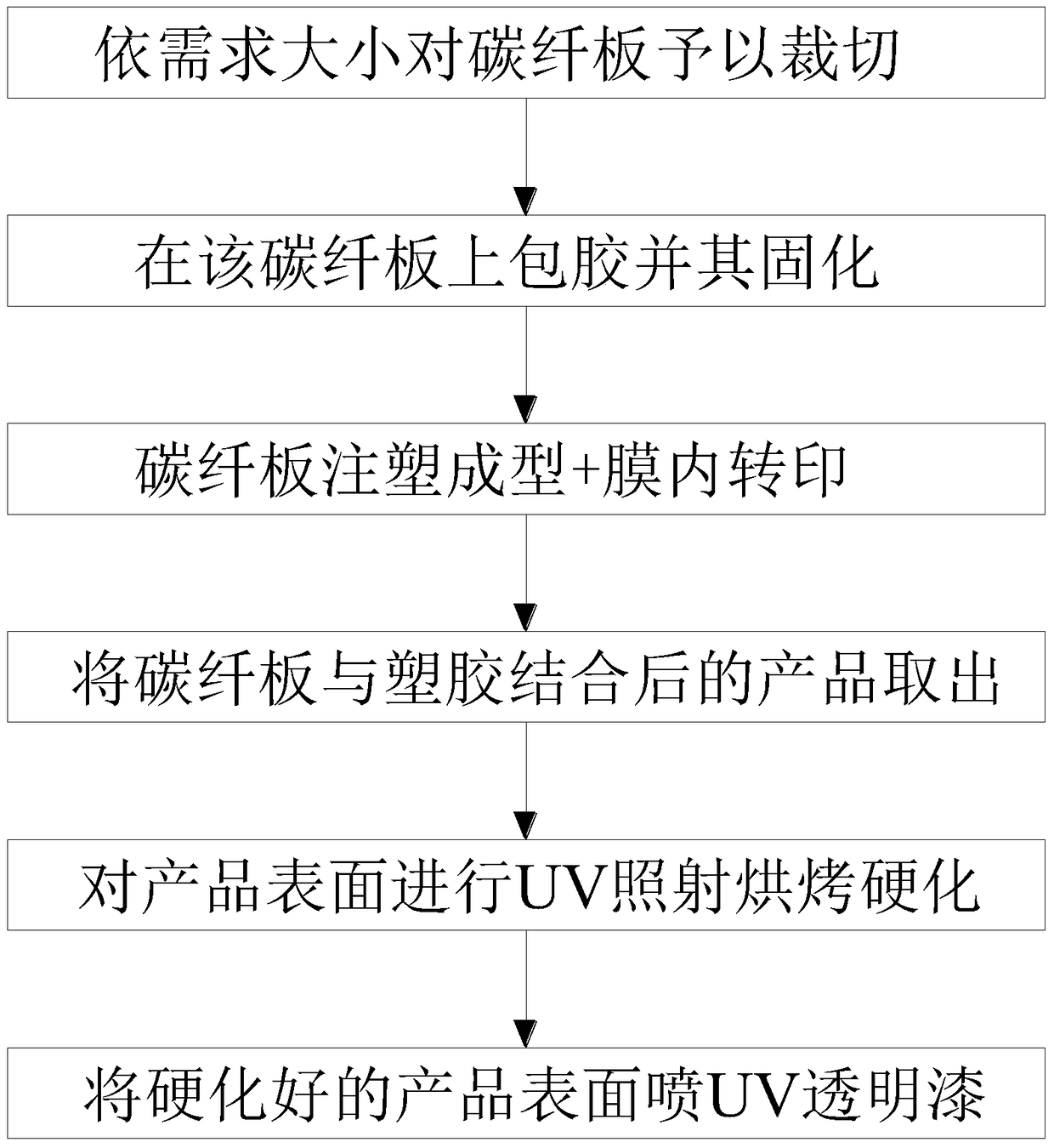

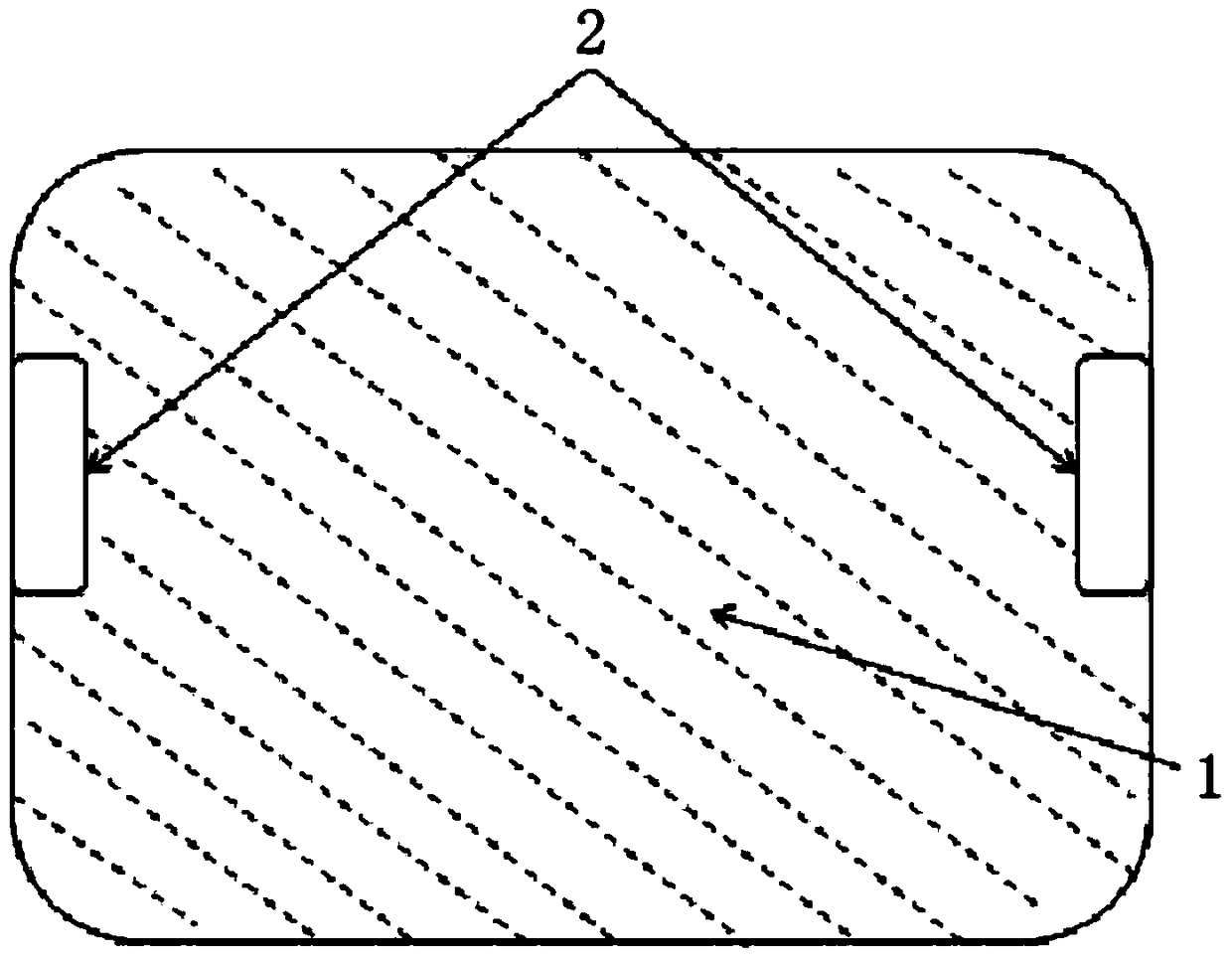

[0034] Example: such as figure 1 As shown, a carbon fiber plate surface processing method specifically includes the following steps:

[0035] Step 1: Cut the carbon fiber board 1 according to the required size. In this embodiment, the thickness of the carbon fiber board 1 is within 1.0mm, and the cutting method adopts CNC cutting;

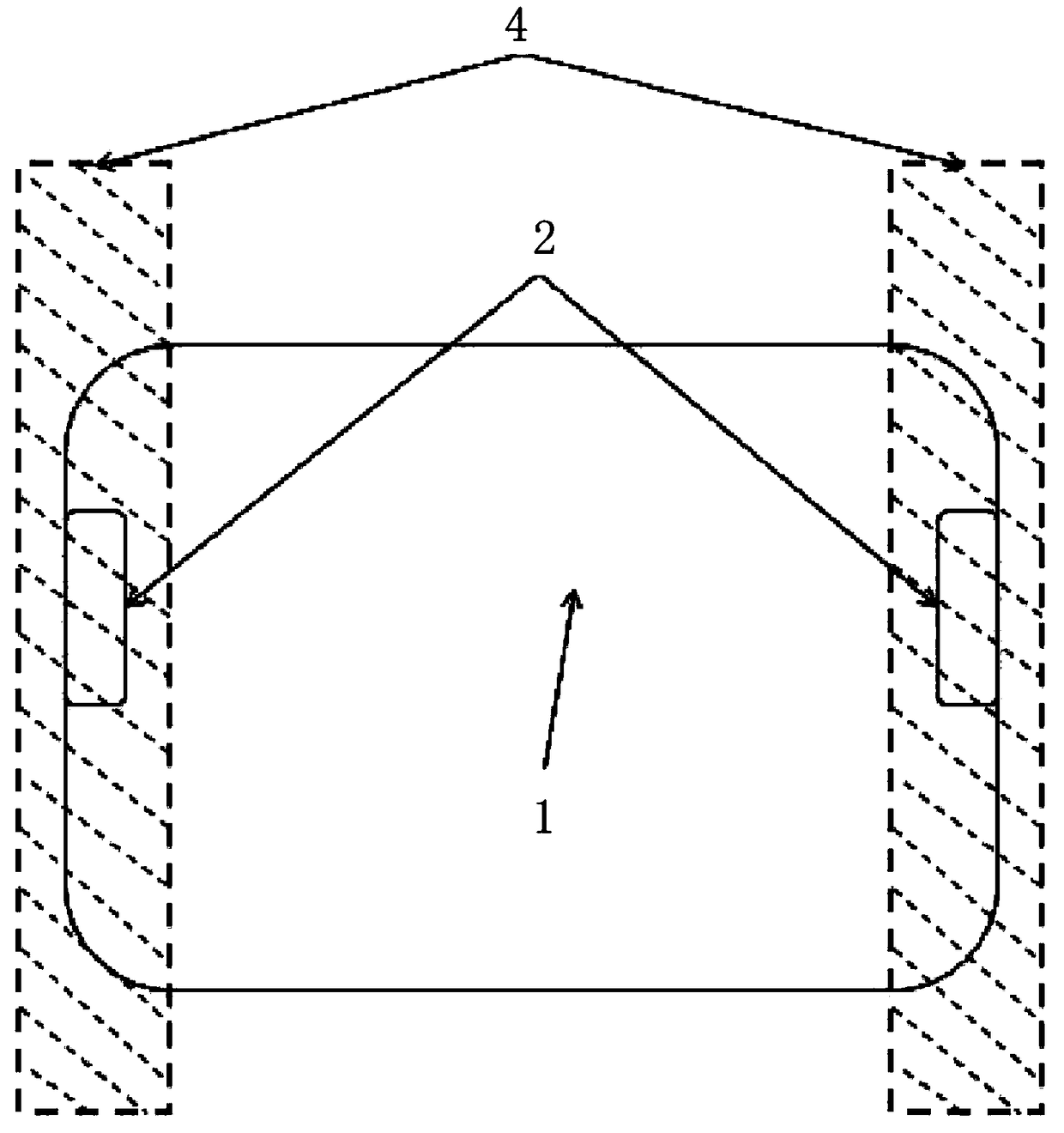

[0036] Step 2: Cover the carbon fiber board 1 with glue to form an adhesive surface, bake it to solidify, and put it into the injection molding device 3;

[0037] Step 3: Put the foil film 4 into the injection molding device 3 by using the automatic foil feeding machine 5, and after the foil film 4 printed with the carbon fiber pattern is calibrated with the transfer area through the infrared positioning sensor 6, the injection molding device is placed on the carbon fiber board 1 Plastic 2 is injection-molded, and at the same time, the pattern of the carbon fiber board on the foil film 4 is transferred to the surface of the plastic 2 of the carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com