Electric melting furnace flue gas treatment device and method

A flue gas treatment and electric melting furnace technology, applied in the field of air pollution control, can solve the problems of easy poisoning of catalysts, low equipment requirements, low denitrification efficiency, etc., and achieve the effect of purification and saving ammonia consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

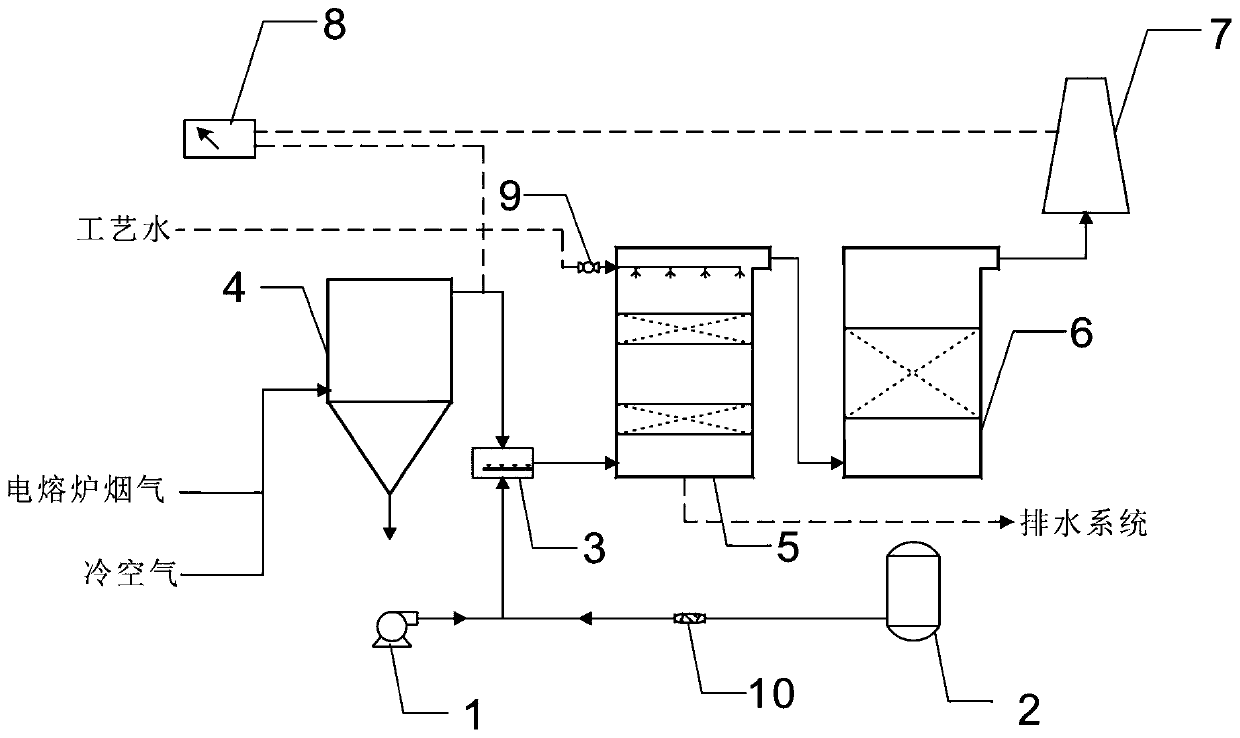

[0035] The method for treating the above-mentioned electric melting furnace flue gas treatment device with electric melting furnace flue gas includes the following steps:

[0036] (1) The air volume control system introduces cold air into the flue gas of the electric smelter produced by the production device. The volume ratio of the cold air to the flue gas of the electric smelter is 4.2:1. After mixing, it is passed into the dust collector 4 to remove dust, and the flue gas after dust removal is obtained. ;

[0037] (2) Turn on the dilution fan 1 and the transfer pump 10 to pass the diluted ammonia water into the atomization device 3, and then mix with the dust-removed flue gas obtained in step (1) and pass it into the pretreatment tower 5, after filtering and adsorption treatment Afterwards, get desulfurization flue gas;

[0038] (3) Pass the desulfurization flue gas obtained in step (2) into SCR reactor 6 with a space velocity of 5000h -1 , The flue gas temperature is 120°C, and ...

Embodiment 2

[0041] The method for treating the above-mentioned electric melting furnace flue gas treatment device with electric melting furnace flue gas includes the following steps:

[0042] (1) The air volume adjustment system introduces cold air into the flue gas of the electric smelter produced by the production device. The volume ratio of the cold air to the flue gas of the electric smelter is 3.25:1. After mixing, it is passed into the dust collector 4 to remove dust, and the flue gas after dust removal is obtained. ;

[0043] (2) Turn on the dilution fan 1 and the transfer pump 10 to pass the diluted ammonia water into the atomization device 3, and then mix with the dust-removed flue gas obtained in step (1) and pass it into the pretreatment tower 5, after filtering and adsorption treatment Afterwards, get desulfurization flue gas;

[0044] (3) Pass the desulfurization flue gas obtained in step (2) into the SCR reactor 6, with a space velocity of 2000h -1 , The flue gas temperature is 15...

Embodiment 3

[0047] The method for treating the above-mentioned electric melting furnace flue gas treatment device with electric melting furnace flue gas includes the following steps:

[0048] (1) The air volume control system passes cold air into the flue gas of the electric smelter produced by the production device. The volume ratio of the cold air and the flue gas of the electric smelter is 5:1. After mixing, it is passed into the dust collector 4 to remove dust, and the flue gas after dust removal is obtained. ;

[0049] (2) Turn on the dilution fan 1 and the transfer pump 10 to pass the diluted ammonia water into the atomization device 3, and then mix with the dust-removed flue gas obtained in step (1) and pass it into the pretreatment tower 5, after filtering and adsorption treatment Afterwards, get desulfurization flue gas;

[0050] (3) Pass the desulfurization flue gas obtained in step (2) into the SCR reactor 6, with a space velocity of 1000h -1 , The temperature is 180 ℃, and then reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com