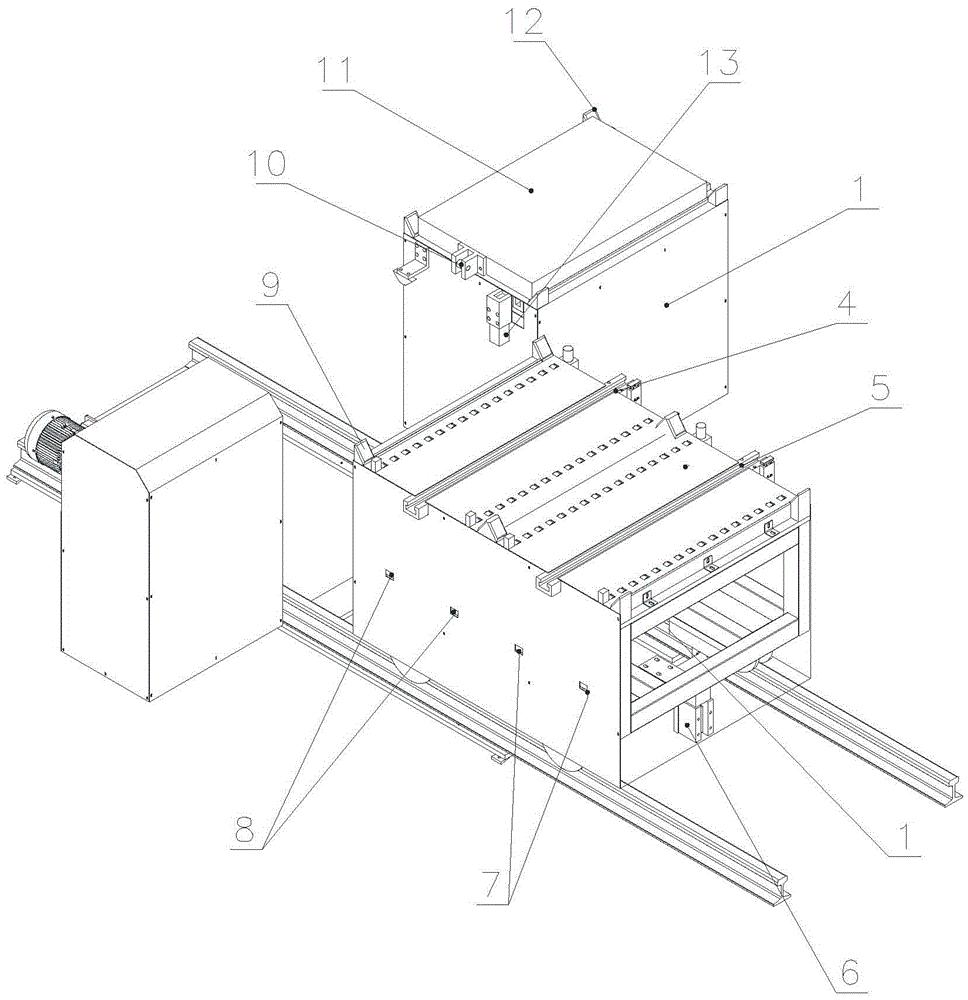

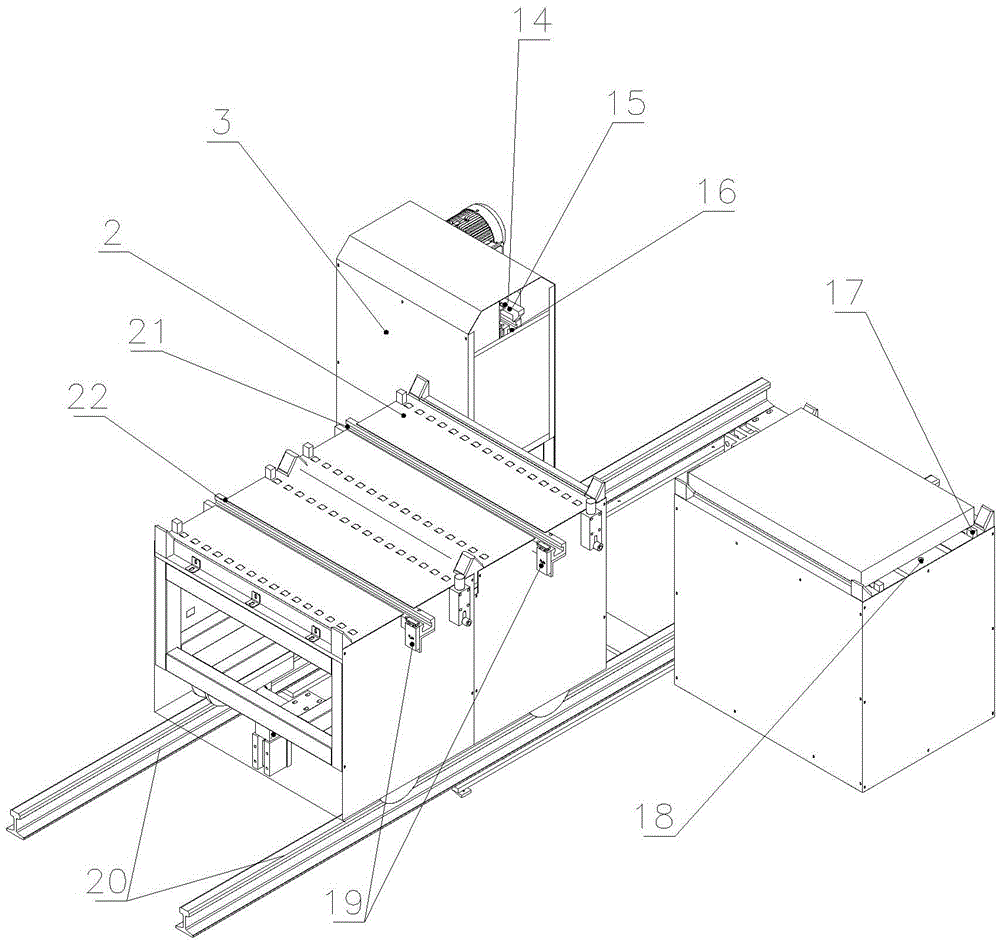

Full-automatic mold replacing trolley system

A mold trolley, fully automatic technology, applied in conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of abnormally frequent mold change of the press, high labor intensity of operators, and low mold change efficiency. Achieve the effect of improving equipment utilization, reducing labor intensity of workers, and reducing space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

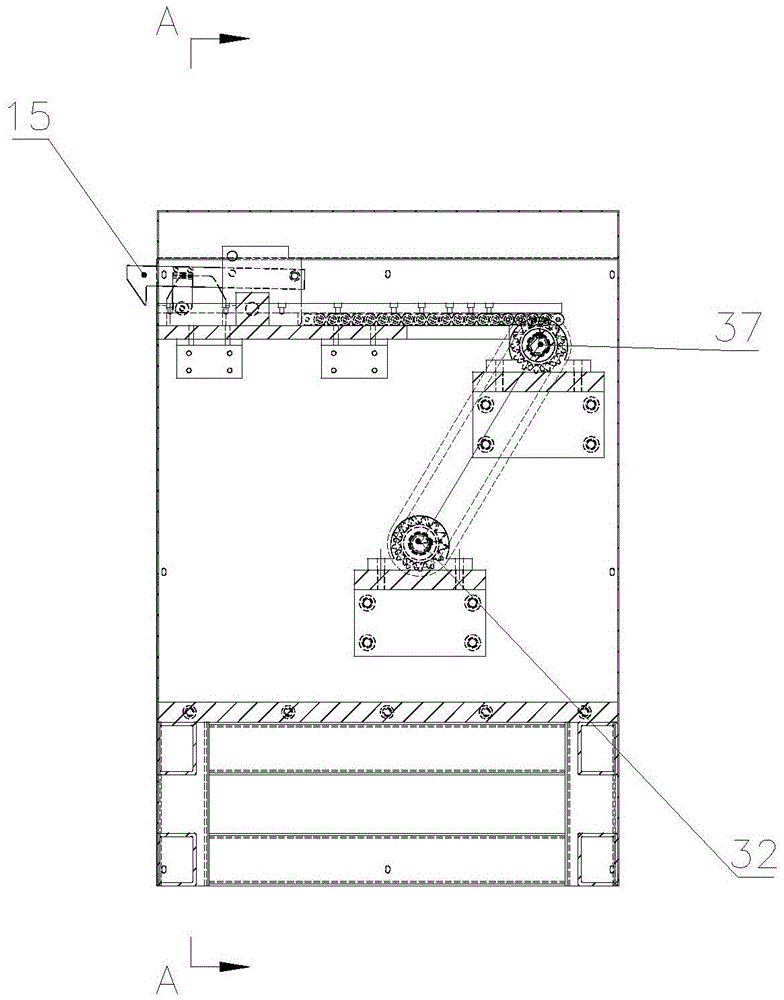

Method used

Image

Examples

Embodiment 1

[0019] State before implementation: there is mold A on machine device 1, no mold in area A, and mold B in area B;

[0020] Implementation content, change the mold B in area B to machine device 1, the specific steps are as follows:

[0021] (1) Press the start button, the module detector 18 detects that there is a mold on the machine, the lower cylinder 6 of the trolley retracts, the upper proximity switch on the lower cylinder 6 of the trolley has a signal, the indicator light is on, and the trolley device 2 starts , the trolley moves forward;

[0022] (2) The detector three left 8 receives the signal, the indicator light is on, the trolley device 2 starts to decelerate and arrives at the designated position, the T slot 21 in the A area on the trolley device 2 is aligned with the push-pull T slot 16 on the push-pull mechanism 3, The bottom cylinder 6 of the backstage car stretches out in 1 second, and the trolley device 2 is fixed, and the lower proximity switch on the bottom...

Embodiment 2

[0029] State before implementation: there is mold A on machine device 1, mold B in area A, and no mold in area B;

[0030] Implementation content, change the mold B to the machine device 1, the specific steps are as follows:

[0031] (1) Press the start button, the module detector 18 detects that there is a mold on the machine, the lower cylinder 6 of the trolley retracts, the upper proximity switch on the lower cylinder 6 of the trolley has a signal, the indicator light is on, and the trolley device 2 starts , the trolley moves forward;

[0032] (2) The detector three right 7 receives the signal, the indicator light is on, the trolley arrives at the designated position, the T slot 22 in area B is aligned with the push-pull T slot 16, and the lower cylinder 6 of the backstage trolley extends out in 1 second, and the trolley device 2 is fixed. The lower proximity switch on the bottom cylinder 6 of the trolley has a signal, and the indicator light is on, and the hook 15 advance...

Embodiment 3

[0039] State before implementation: There is no mold on machine device 1, there is mold A in area A, and mold B in area B;

[0040] Implementation content, change the mold A to the machine device 1, the specific steps are as follows:

[0041] (1) Press the start button, the module detector 18 has no signal, the lower cylinder 6 of the trolley retracts, the upper proximity switch on the lower cylinder 6 of the trolley has a signal, the indicator light is on, the trolley device 2 starts, and the trolley moves forward ;

[0042] (2) The detector three left 8 receives the signal, the indicator light is on, the trolley device 2 starts to decelerate and arrives at the designated position, the T slot 21 in the A area on the trolley device 2 is aligned with the push-pull T slot 16 on the push-pull mechanism 3, 1 second, the lower cylinder 6 of the backstage car stretches out, the trolley device 2 is fixed, the lower proximity switch on the lower cylinder 6 of the trolley has a signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com