Breeding circulating water treatment system and process method thereof

A treatment system and circulating water technology, applied in biological water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low filtration efficiency of physical purification devices, large load of biological purification devices, Problems such as poor mass transfer characteristics, to achieve the effect of improving free sedimentation effect, improving removal rate, and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

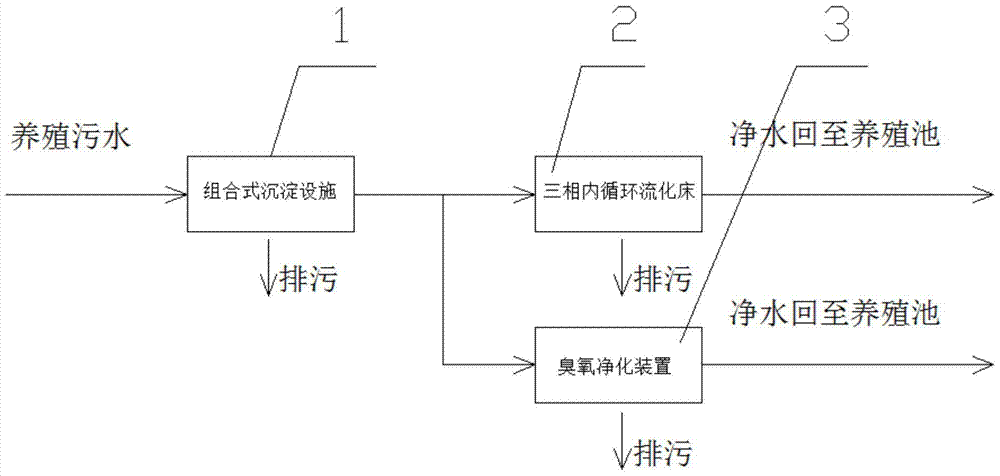

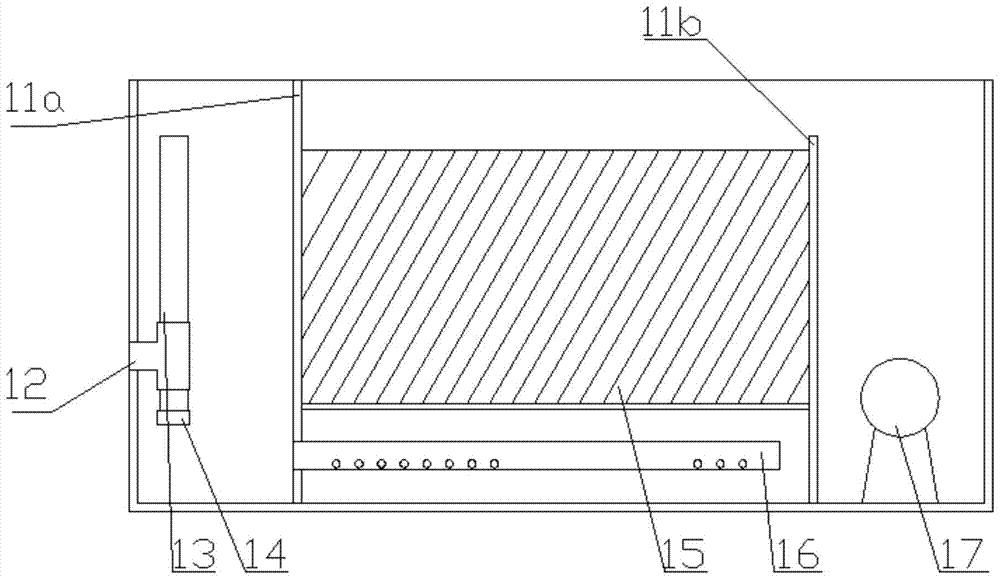

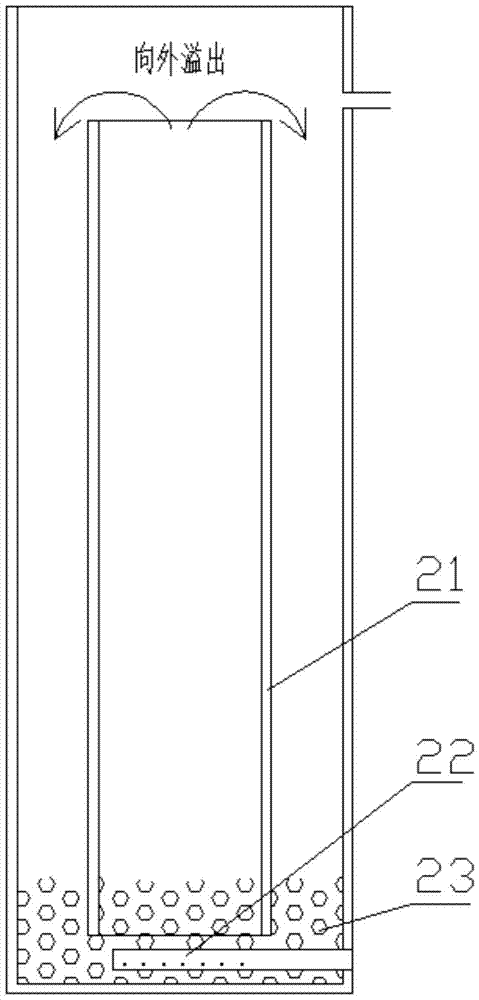

[0032] see Figure 1-Figure 3 :

[0033] 1) The combined sedimentation facility 1 is divided into three cavities by the first and second inner partitions 11a, 11b. The top elevation of each cavity is the same as that of the culture tank, and the bottom elevation is the same, and the bottom of each cavity is equipped with a drain . The anterior cavity is communicated with the culture pond through the connecting pipe 12, the upper end of the connecting pipe is inserted into the movable standpipe 13, and the lower end is connected to the plug 14. The length of the moving standpipe is determined according to the required water level in the culture pond; the middle cavity is divided into two layers, the upper layer is the filter material layer, and the lower layer is the water distribution structure layer. The filter material layer is composed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com