Aluminum electrolysis production process multi-objective optimization method based on adaptive-step bacterial foraging algorithm

A bacterial foraging algorithm and self-adaptive step size technology, applied in the multi-objective optimization field of aluminum electrolysis production process, can solve problems such as low efficiency, difficult real-time measurement and adjustment, high energy consumption, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

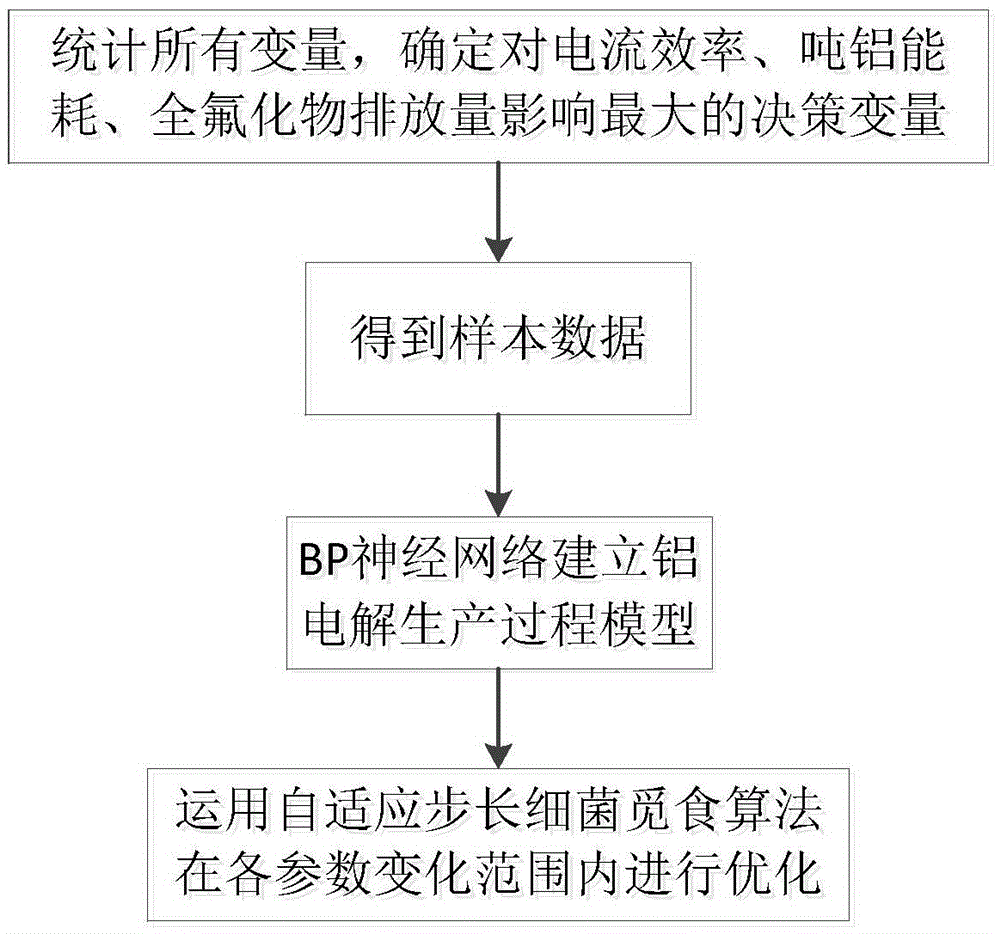

[0038] Such as figure 1 A multi-objective optimization method for the production process of aluminum electrolysis based on the adaptive step-size bacterial foraging algorithm is shown, the key of which is to include the following steps:

[0039] S1: Select 3 aluminum electrolysis production indicators Y=[y 1 ,y 2 ,y 3 ], including: current efficiency, energy consumption per ton of aluminum and emissions of perfluorinated compounds;

[0040] Select 8 parameters X=[x 1 ,x 2 ,...x 8 ], including: series current, NB times, molecular ratio, aluminum output, aluminum level, electrolyte level, bath temperature, bath voltage.

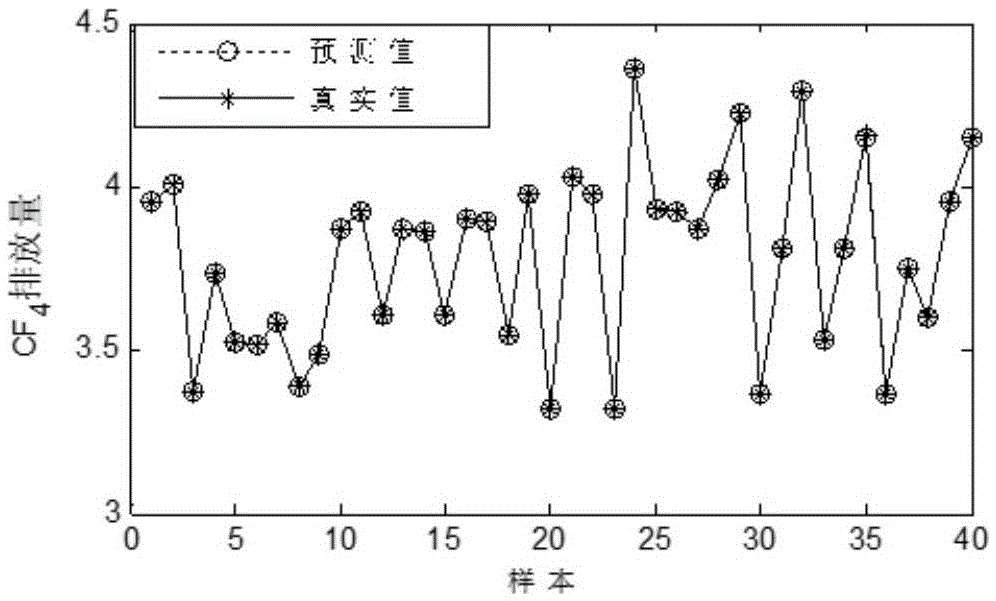

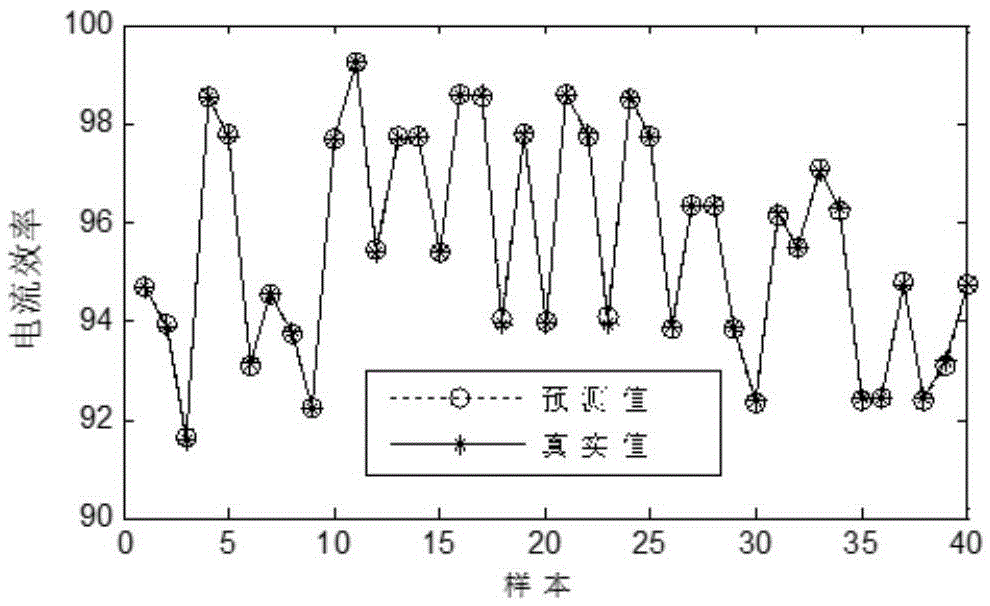

[0041] S2: Using the parameter X as input and the production index Y as output, use the BP neural network to model the aluminum electrolysis process to obtain an aluminum electrolysis model; the BP neural network modeling process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com