A method for controlling the top surface line shape of concrete foundation bed

A control method and concrete technology, applied in roads, tracks, buildings, etc., can solve the problems of difficult control of plastering quality, large human factors, and a large number of personnel, and achieve the effects of saving labor hours, good appearance quality, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

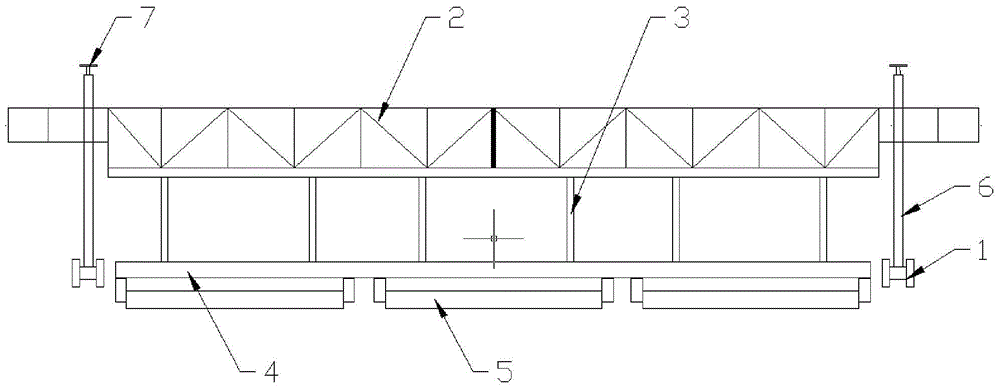

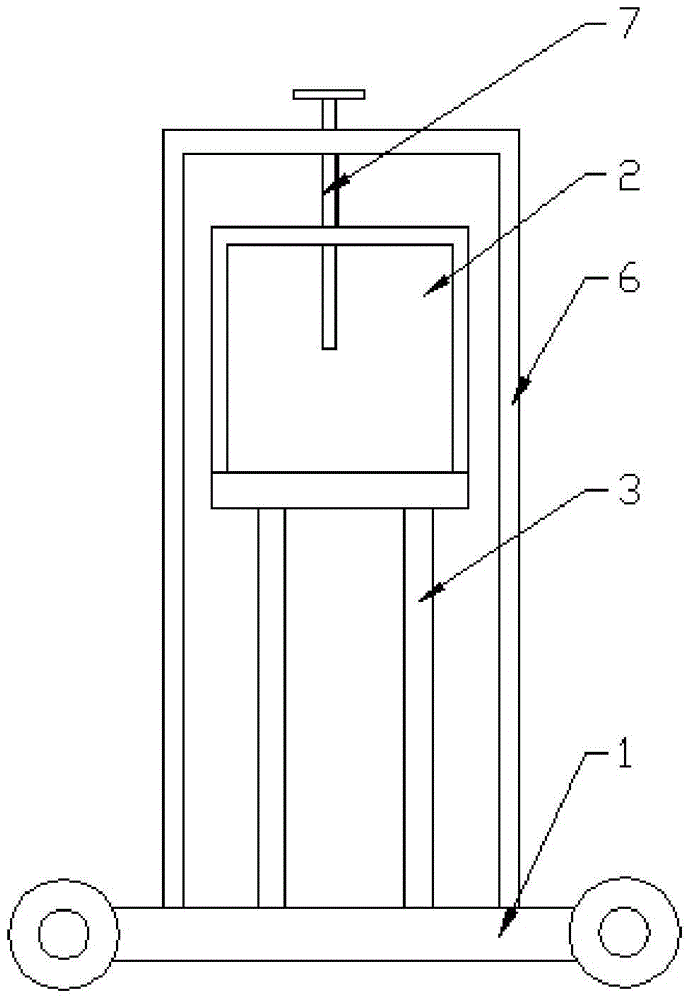

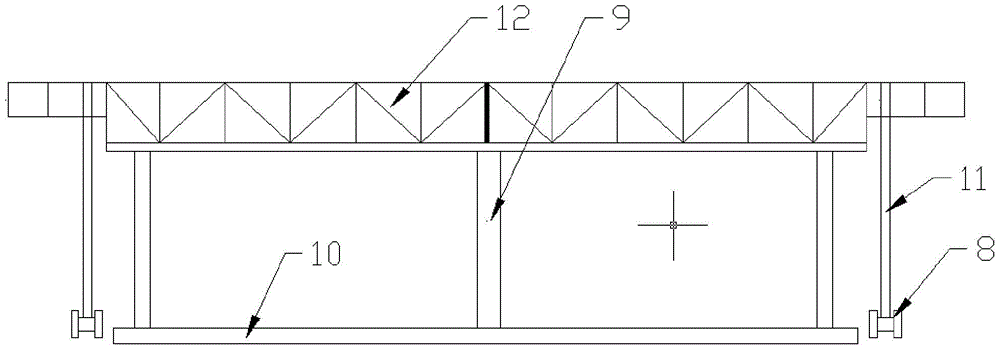

Method used

Image

Examples

Embodiment

[0022] The main indicators of the concrete foundation bed are as follows:

[0023] Embankment section - the total thickness of the subgrade bed of the main line of the ballastless track is 2.7m, and the range of the subgrade bed from top to bottom is C35 concrete, C20 concrete, mixed with 5% cement graded crushed stone, and A and B groups of fillers. Among them, the thickness of C35 concrete is 0.5m, the thickness of C20 concrete is the maximum freezing depth minus 0.5m, and the thickness of graded gravel mixed with 5% cement is the design freezing depth minus the maximum freezing depth.

[0024] Hard rock cutting section——cut out the original stratum within 0.2m below the subgrade surface of the hard rock bed section, wash it with high-pressure water, pour C35 plain concrete seal, and configure φ12@200 gluten.

[0025] Soft rock cutting section—concrete bed shall be used within the design frozen depth range, and 0.5m thick C35 concrete shall be poured on the surface of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com