Cement-based non-metal sound barrier unit plate

A sound barrier and unit board technology, which is applied in applications, household appliances, construction, etc., can solve the problems of easy rust and oxidation of screws, affecting sound absorption effect, troublesome assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

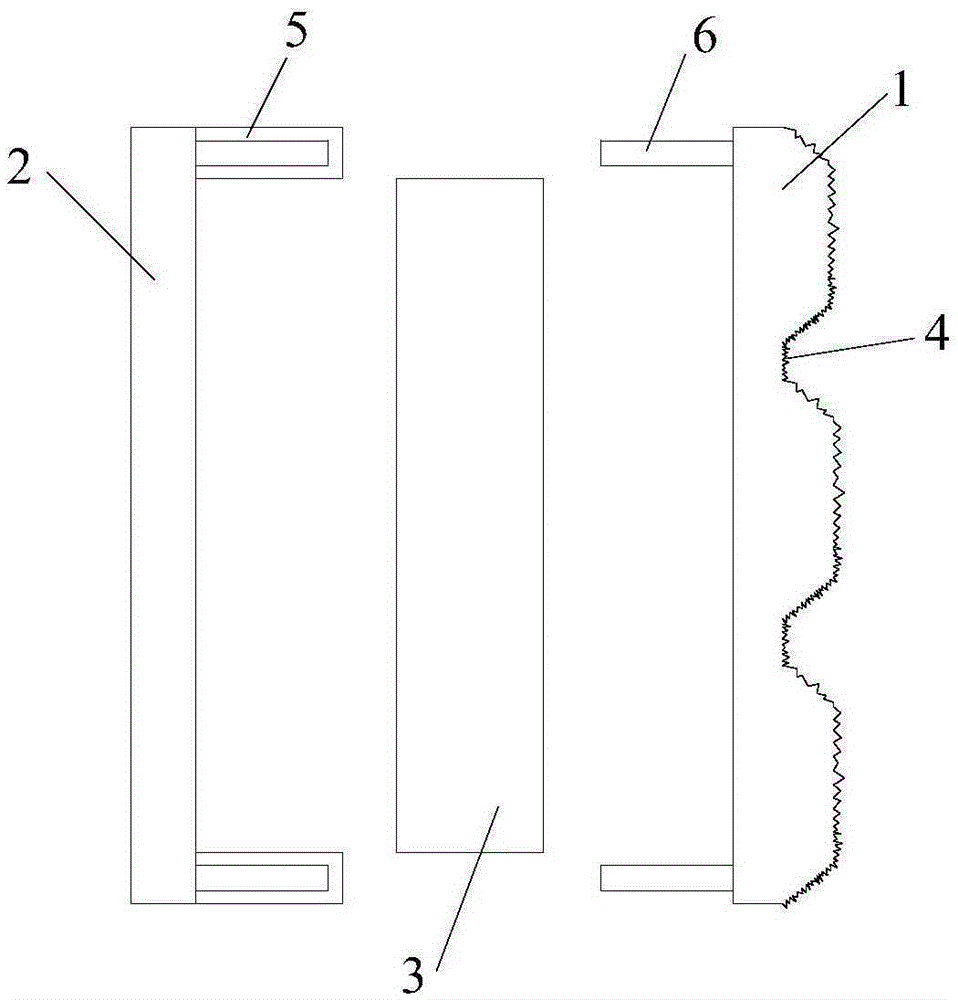

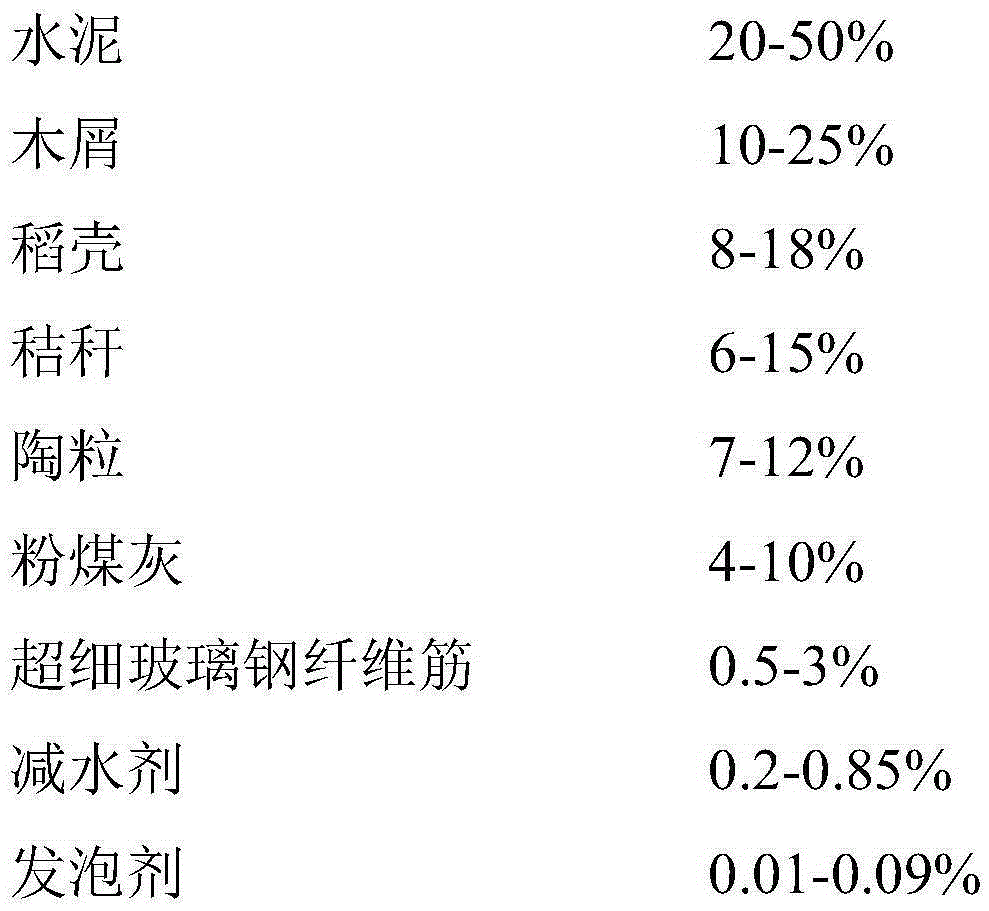

[0020] see figure 1 , a cement-based non-metallic sound barrier unit panel proposed by the present invention, comprising a sound-absorbing panel 1, a sound-insulating panel 2, and a sound-absorbing material 3 arranged between the sound-absorbing panel 1 and the sound-insulating panel 2, and the sound-absorbing material 3 Comprising the following components in weight percent:

[0021]

[0022] Among them, the average particle size of the ceramsite is 2cm, the average diameter of the ultra-fine fiberglass reinforcement is 25μm, the water reducer is lignosulfonate, and the foaming agent is sodium lauryl sulfate.

[0023] The interior of the sound insulation board 2 is mixed with threaded fiberglass reinforcement. The sound-absorbing panel 1 is provided with grooves 4 along its transverse direction, and the surface of the sound-absorbing panel 1 presents irregular concave-convex granular distribution. The sound-absorbing panel 1 is provided with a pipe 5 , and the interior of...

Embodiment 2

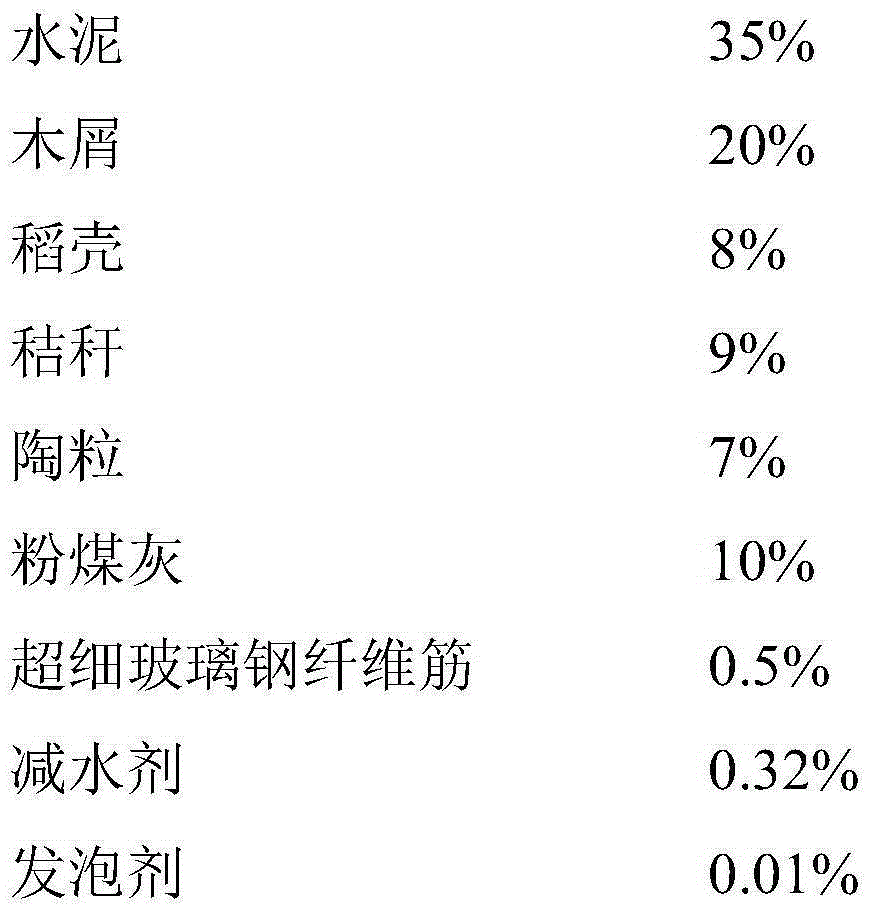

[0025] see figure 1 , a cement-based non-metallic sound barrier unit panel proposed by the present invention, comprising a sound-absorbing panel 1, a sound-insulating panel 2, and a sound-absorbing material 3 arranged between the sound-absorbing panel 1 and the sound-insulating panel 2, and the sound-absorbing material 3 Comprising the following components in weight percent:

[0026]

[0027]

[0028] Among them, the average particle size of the ceramsite is 2cm, the average diameter of the ultra-fine fiberglass reinforcement is 25μm, the water reducer is lignosulfonate, and the foaming agent is sodium lauryl sulfate.

[0029] The interior of the sound insulation board 2 is mixed with threaded fiberglass reinforcement. The sound-absorbing panel 1 is provided with grooves 4 along its transverse direction, and the surface of the sound-absorbing panel 1 presents irregular concave-convex granular distribution. The sound-absorbing panel 1 is provided with a pipe 5 , and the...

Embodiment 3

[0031] see figure 1 , a cement-based non-metallic sound barrier unit panel proposed by the present invention, comprising a sound-absorbing panel 1, a sound-insulating panel 2, and a sound-absorbing material 3 arranged between the sound-absorbing panel 1 and the sound-insulating panel 2, and the sound-absorbing material 3 Comprising the following components in weight percent:

[0032]

[0033] Among them, the average particle size of the ceramsite is 2cm, the average diameter of the ultra-fine fiberglass reinforcement is 25μm, the water reducer is lignosulfonate, and the foaming agent is sodium lauryl sulfate.

[0034] The interior of the sound insulation board 2 is mixed with threaded fiberglass reinforcement. The sound-absorbing panel 1 is provided with grooves 4 along its transverse direction, and the surface of the sound-absorbing panel 1 presents irregular concave-convex granular distribution. The sound-absorbing panel 1 is provided with a pipe 5 , and the interior of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com