A lock-type building composite thermal insulation component and its composition

A technology of thermal insulation components and locks, which is applied to building components, thermal insulation, climate change adaptation, etc., can solve problems such as poor earthquake resistance and fire protection, low construction efficiency, inability to save energy and protect the environment, and achieve high environmental protection index and crack resistance standards. The effect of efficiency and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

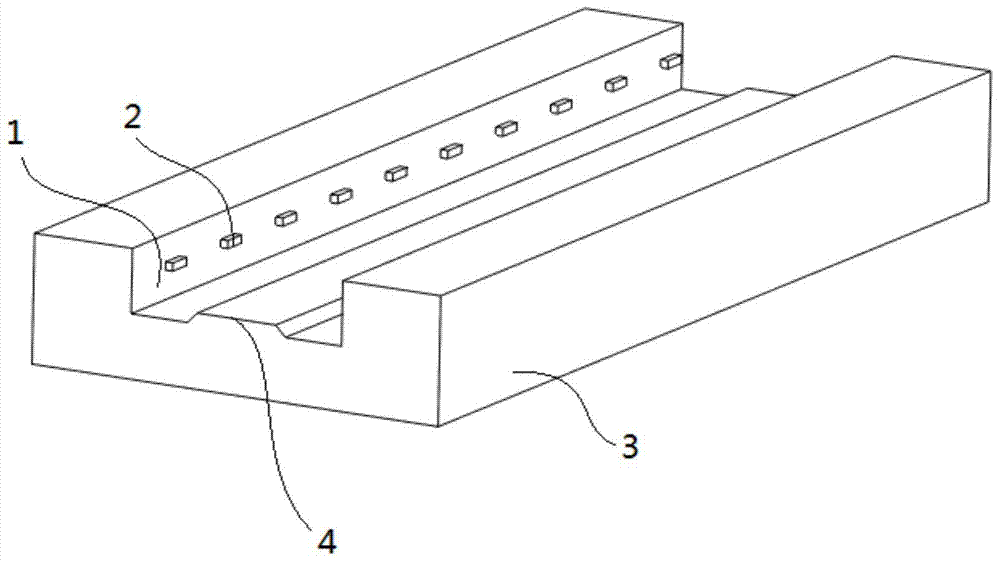

[0035] A lock type building combination thermal insulation component, including a main body 3, the outer surface of the main body 3 is rectangular, and a groove 1 is provided in the middle of one end surface of the main body 3, and the width of the groove 1 is half of the width of the rectangle, so as to prevent the components from There is an excessively large gap between the grooves. The side of the groove 1 is provided with a row of locks 2. The distance between adjacent locks 2 is greater than the length of the locks 2 itself, and the distance between the locks 2 and the top surface of the groove 1 is smaller than that of the locks. 2. The distance from the bottom surface of the groove 1 is such that when the upper and lower components are locked, the locks are staggered from each other, and a boss 4 is provided on the bottom surface of the groove 1.

[0036] Considering actual needs, the groove 1 is a rectangular groove, and the lock catch 2 is arranged on the left and rig...

Embodiment 2

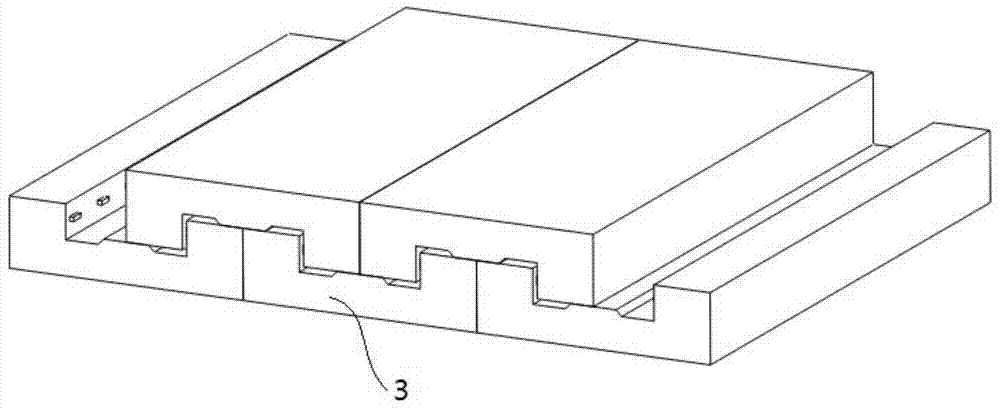

[0042] A lock type building combination thermal insulation component, including a main body 3, the outer surface of the main body 3 is rectangular, and a groove 1 is provided in the middle of one end surface of the main body 3, and the width of the groove 1 is half of the width of the rectangle, so as to prevent the components from There is an excessively large gap between the grooves. The side of the groove 1 is provided with a row of locks 2. The distance between adjacent locks 2 is greater than the length of the locks 2 itself, and the distance between the locks 2 and the top surface of the groove 1 is smaller than that of the locks. 2 and the bottom surface of the groove 1, so that when the upper and lower components are locked, the lock catches 2 are staggered from each other, and the bottom surface of the groove 1 is provided with two bosses.

[0043] Considering actual needs, the groove 1 is a rectangular groove, and the lock catch 2 is arranged on the left and right sid...

Embodiment 3

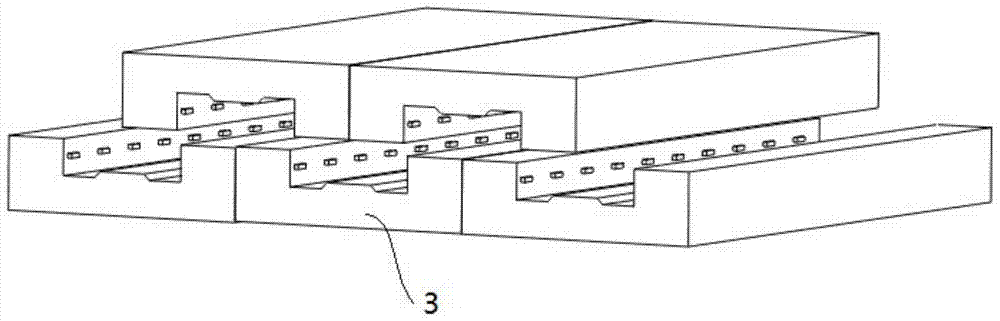

[0049] A lock type building combination thermal insulation component, including a main body 3, the outer surface of the main body 3 is rectangular, and a groove 1 is provided in the middle of one end surface of the main body 3, and the width of the groove 1 is half of the width of the rectangle, so as to prevent the components from There is an excessively large gap between the grooves. The side of the groove 1 is provided with a row of locks 2. The distance between adjacent locks 2 is greater than the length of the locks 2 itself, and the distance between the locks 2 and the top surface of the groove 1 is smaller than that of the locks. 2 and the bottom surface of the groove 1, so that when the upper and lower components are locked, the lock catches 2 are staggered from each other, and a boss 4 is provided on the bottom surface of the groove 1.

[0050] Considering actual needs, the groove 1 is a rectangular groove, and the locks are arranged on the left and right sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com