Hydraulic automatic blowout control controller

An automatic controller and hydraulic technology, applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as complex operation process of blowout prevention tools, impact on production efficiency, surface pollution, etc., to ensure The effect of green and environmental protection operation construction, efficient well cleaning, and prevention of energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

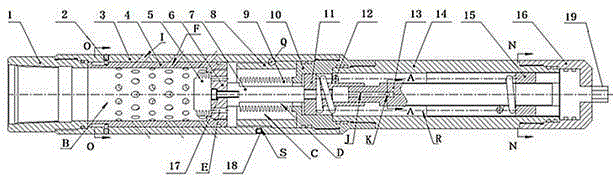

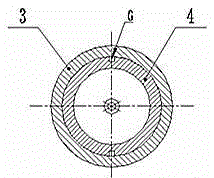

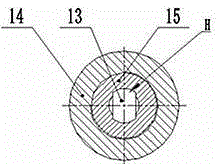

[0012] See Figure 1-4 , the specific structure of the present invention is as follows: the external thread of the lower end of the upper joint 1 is connected with the internal thread of the upper end of the outer sleeve 3 and sealed by an O-shaped rubber ring, the piston 4 is housed in the outer sleeve 3, and the piston 4 and the circumferential surface of the outer sleeve 3 are provided with Corresponding to a plurality of inclined holes I, F, the inclined hole I on the outer sleeve 3 communicates with the inclined hole F on the piston 4; The lower end of the piston 4 is connected to the piston plug 6 through threads, and there are two liquid inlet holes E on the piston plug 6. The polytetrafluoro bellows 5 is connected to the upper end of the piston plug 6, and the piston plug 6 and the transmission shaft 7 are connected by screws. 17 connection; the transmission shaft 7 is fitted with a bellows 9 to form an air cavity D, the upper end of the bellows is sealed and connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com