Engine combined-cooling system on small single-rotor-wing unmanned helicopter

An unmanned helicopter and hybrid cooling technology, applied in machine/engine, engine components, engine sealing devices, etc., can solve the problems of single engine cooling method and good heat dissipation effect, and achieve extended flight time, excellent heat dissipation effect, etc. Optimum cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

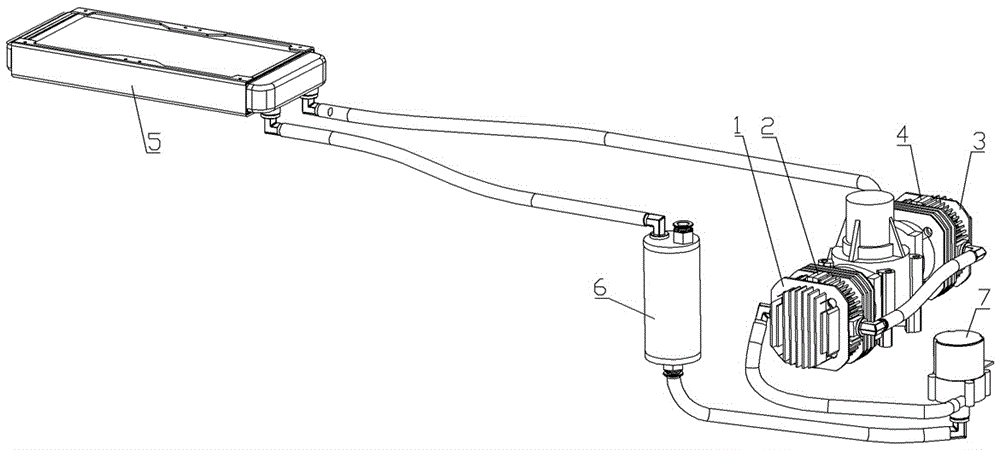

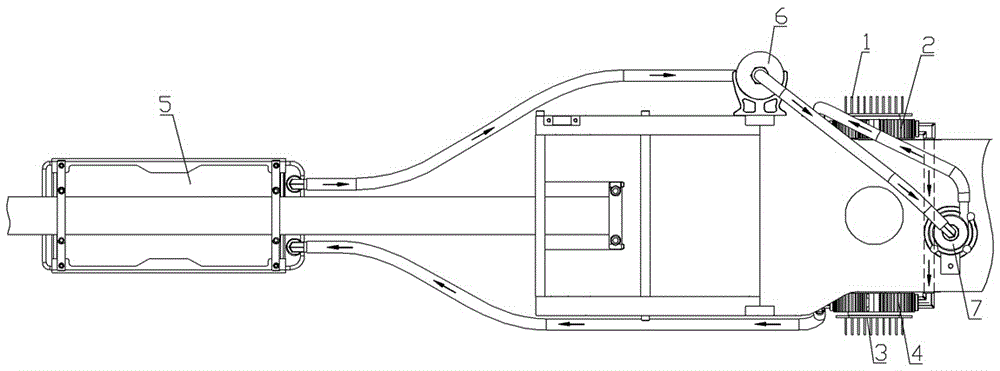

[0029] Such as figure 1 , 2 Shown: The hybrid engine cooling system on a small single-rotor unmanned helicopter, including cylinder block A1, water cooling jacket A, cylinder block B3, water cooling jacket B, water cooling evaporator 5, water storage tank 6 and water pump 7;

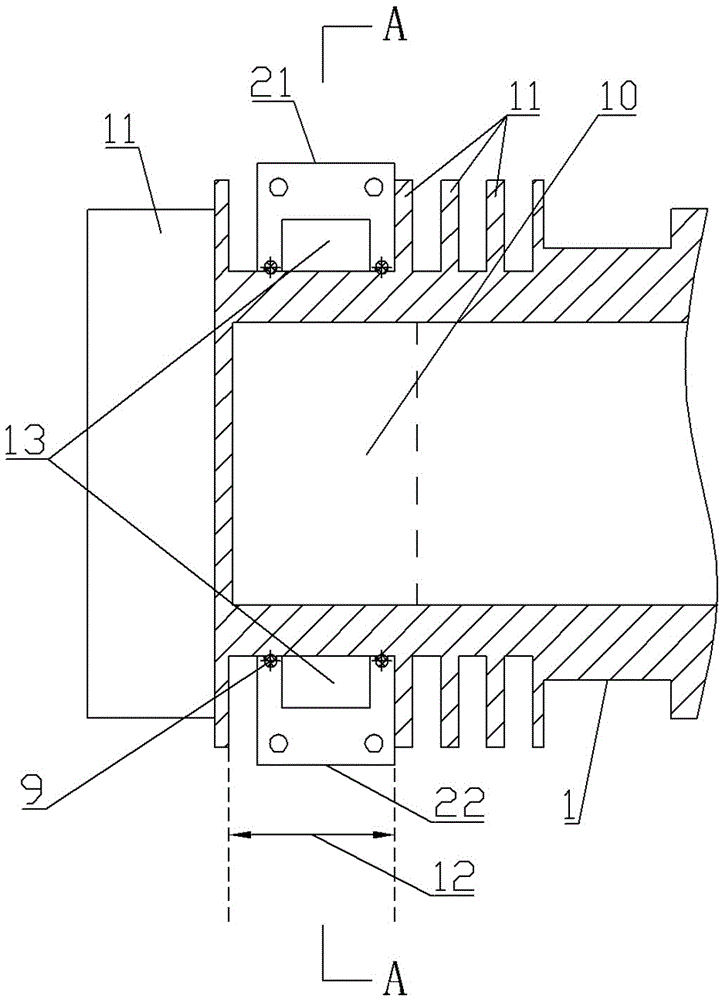

[0030] The outer wall of the cylinder body A1 is provided with a plurality of heat dissipation fins 11, and the outer wall of the cylinder body A1 is provided with an annular vacancy zone 12 that is not connected to the heat dissipation fins (such as image 3 , 4 shown). The water-cooling jacket A includes an upper arc-shaped sleeve 21 and a lower arc-shaped sleeve 22; the upper and lower arc-shaped sleeves are installed on the annular vacant belt 12 of the cylinder A1 and connected into a ring by bolts, and the water tanks on the inner arc surfaces of the two are connected. An annular water tank is formed, and an annular water cavity A13 is formed between the annular water tank and the cylinder A1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com