Intelligent control system and method for combustion process of hot-blast stove

An intelligent control system and combustion process technology, applied in the control of combustion, fluid heaters, lighting and heating equipment, etc., can solve the problems of violent changes, difficult to establish mathematical models, large amplitude, etc., to achieve the effect of flow optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

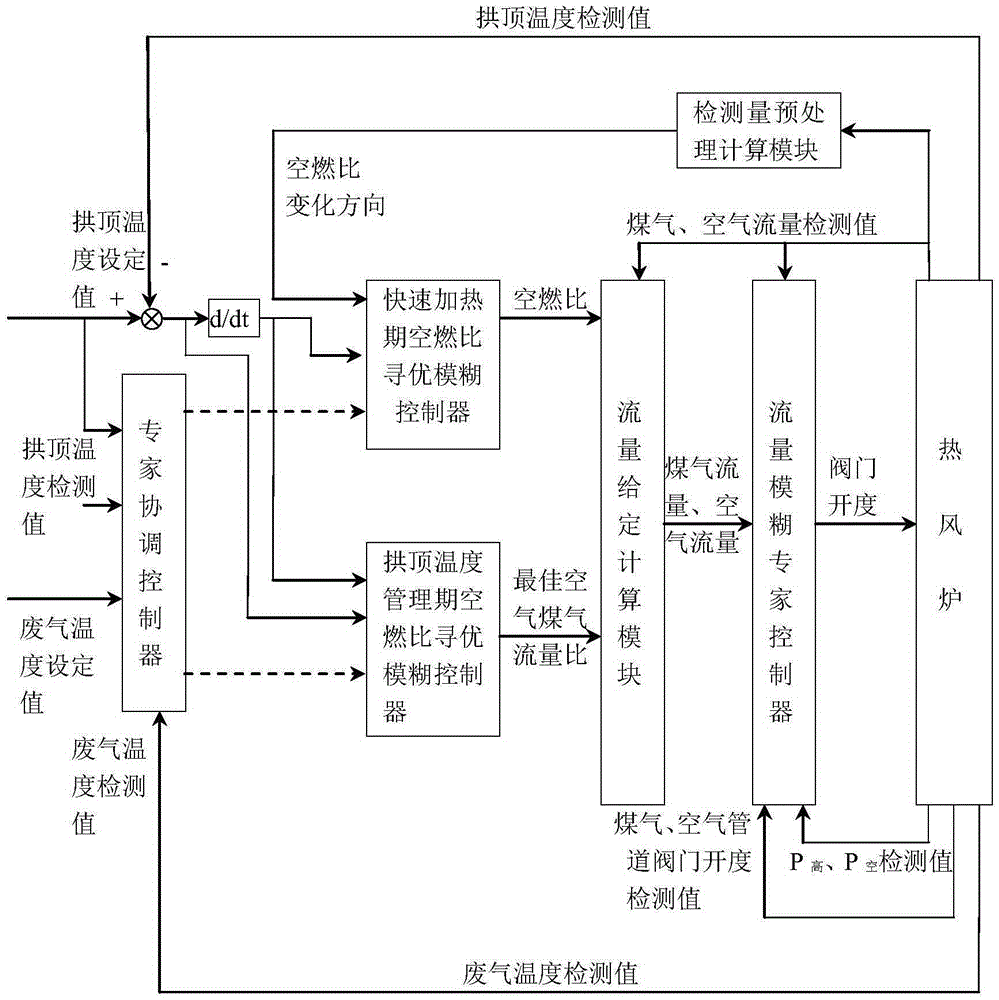

[0071] Such as figure 1 As shown, an intelligent control system for the combustion process of a hot blast stove includes:

[0072] The expert coordination controller is used to identify the combustion state by judging the vault temperature detection value and setting value and the exhaust gas temperature detection value and setting value, and at the same time to select the fuzzy controller for different combustion stages.

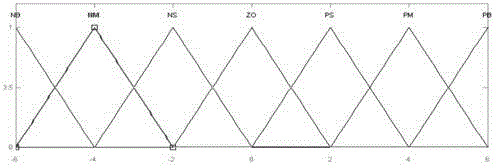

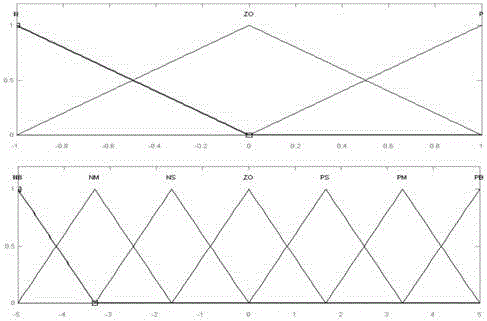

[0073] The air-fuel ratio optimization fuzzy controller in the rapid heating period is used to use the dual-input and single-output control structure during the rapid heating period to calculate the difference e between the current time period and the previous time period rise rate of the vault temperature and the change direction of the air-fuel ratio r is used as the input value, and the adjustment increment of the air-fuel rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com