Supercharged boiler test stand

A pressurized boiler and test bench technology, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of high energy consumption, single function, and imperfect adjustment methods, so as to save production costs and energy The effect of changing consumption and adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

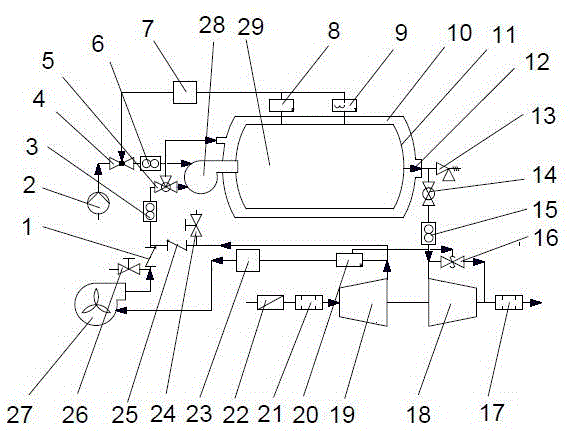

[0028] With reference to accompanying drawing, booster boiler test bench is made up of Roots blower 27, burner 28, boiler 29, turbocharger and fuel pump 2; Turbocharger comprises turbine 18 and compressor 19.

[0029] The Roots fan is connected to the inlet of the burner 28 through the check valve 1, the three-way, the air flow meter 3, and the three-way diverter valve 5 in sequence;

[0030] The inlet of the compressor 19 is connected with a filter 22 and a muffler 21, and the outlet of the compressor is connected to one of the inlets of the tee through a check valve 23;

[0031] The other outlet of the three-way diverter valve is connected to the cooling wind jacket 10;

[0032] The fuel pump 2 is connected to the burner 28 through the flow regulating valve 4 and the fuel flow meter 6;

[0033] The furnace liner of the boiler is connected with a pressure sensor 8 and a thermocouple 9, and the output values of the pressure sensor and the thermocouple are connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com