Method for manufacturing three-dimensional joint-fissure cylindrical rock sample

A technology of joint fissures and rock samples, applied in the field of rock engineering, to achieve reasonable test results, convenient operation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Taking granite taken from a project site as an example, a method for making three-dimensional jointed and fractured cylindrical rock samples is introduced, which includes the following steps:

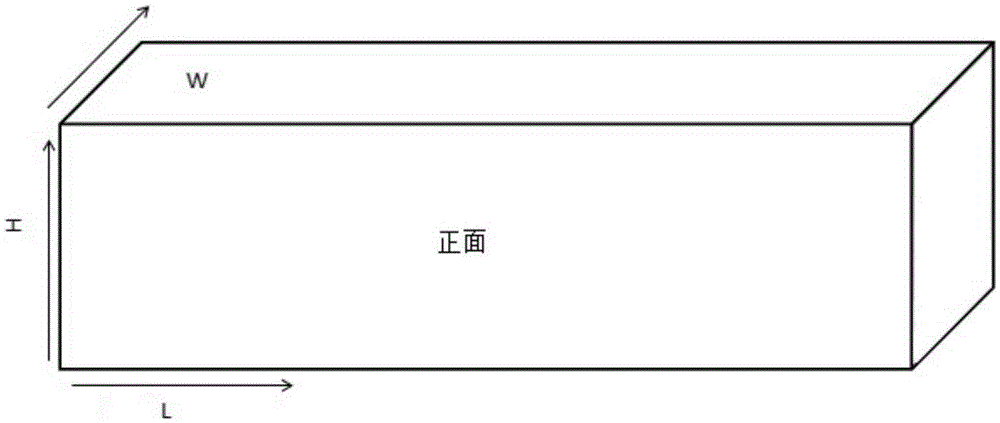

[0036] a. First, sample the engineering rock mass to be tested, and cut the irregular rock blocks obtained from the project site into cuboid-shaped regular rock blocks. The processed rectangular parallelepiped regular granite stones such as figure 1 As shown, the width L of the sample is about 200mm, the height H is about 85mm, and the thickness W is about 50mm;

[0037] b. Place the processed cuboid-shaped regular rock block on the "Yongda" brand high-pressure water jet cutting machine, and cut through-type joint fissures according to the designed geometric parameters. The cut regular cuboid granite blocks with penetrating joints and fissures are as follows: figure 2 As shown, there are single fissure 1, parallel distribution of double fissures 2, parallel distribution of thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com