An automatic detection device and method for locomotive screw looseness

An automatic detection and screw technology, applied in optical testing flaws/defects, image data processing, instruments, etc., can solve the problems of high risk of missed detection and false detection, high unreliability, and reduce locomotive management costs, low costs, and reduced effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

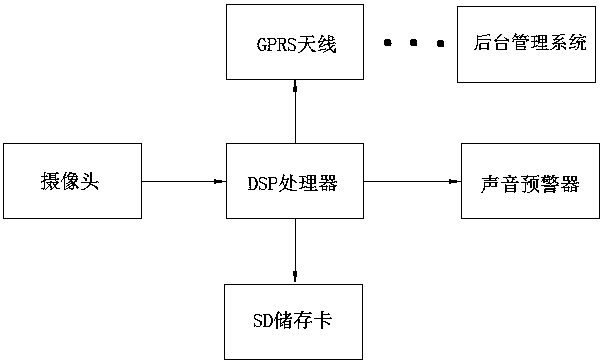

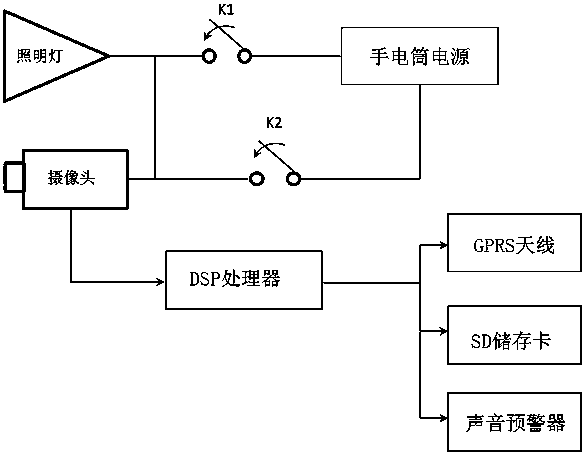

[0036] Such as figure 1 and 2 As shown, the automatic detection device for locomotive screw loosening disclosed by the present invention includes a DSP processor and a camera connected to it respectively, a sound early warning device, a GPRS antenna and an SD memory card, and the automatic detection device for loose screw of a locomotive is assembled on a flashlight , wherein the camera is placed at the position of the lamp holder of the flashlight, and the DSP processor, sound warning device, GPRS antenna and SD memory card are placed inside the cylinder of the flashlight, and the automatic detection button K2 is connected to the camera, and the automatic detection button is connected with the flashlight The lighting switch button K1 is separated. specific:

[0037] The camera is used to collect the anti-loosening marking image of the screw and the corresponding digital identification image, and send it to the DSP processor; such as image 3 As shown, the number identifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com